Acidification blocking removal system and preparation method thereof

A system and volume ratio technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high ground injection pressure, high requirements for ground equipment, high viscosity, etc., and achieve increased seepage resistance and excellent interface properties , Improve the effect of shunting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present application provides a preparation method of an acidification plugging removal system, the acidification plugging removal system is a W / O / W type multiple emulsion, and the method includes the following steps:

[0050] (1) Oil phase preparation: ultrasonically disperse hydrophobic nano-silica particles and surfactants in oil to obtain an oil phase;

[0051] (2) Preparation of inner water phase: dissolving acid, corrosion inhibitor and chelating agent in water to obtain inner water phase;

[0052] (3) W / O type primary phase preparation: the oil phase of step (1) and the inner water phase of step (2) are mixed at a high speed and homogeneously in the ratio of volume ratio (5-2): (5-8), Get W / O type initial phase;

[0053] (4) Preparation of the external water phase: dissolving the water-soluble emulsifier in water to obtain the external water phase;

[0054] (5) The W / O type primary phase of step (3) and the external water phase of step (4) are mixed at a hig...

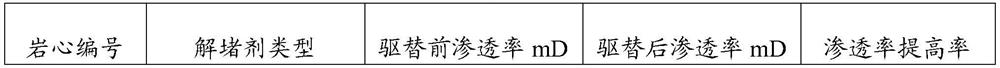

Embodiment 1

[0060] The preparation of the W / O / W type multiple emulsion acidification plugging removal system of this application includes the following steps:

[0061] (1) Oil phase preparation: the surfactant Span60 and hydrophobic nano-silica particles are dissolved in the oil by ultrasonic dispersion to obtain the oil phase; wherein, based on the total mass of the oil phase obtained, the mass fraction of Span60 is 3% , the mass fraction of the hydrophobic nano-silica particles is 0.3%, and the particle size of the hydrophobic nano-silica particles is 30nm; the oil is styrene tar;

[0062] (2) Preparation of internal water phase: based on the total mass of the internal water phase obtained, the mass fraction is 20% hydrochloric acid, 0.5% corrosion inhibitor and 0.5% hydroxyethylidene diphosphonic acid dissolved in water to obtain internal water phase; wherein, the hydrochloric acid is prepared by diluting with 38% analytically pure hydrochloric acid, the corrosion inhibitor is a commer...

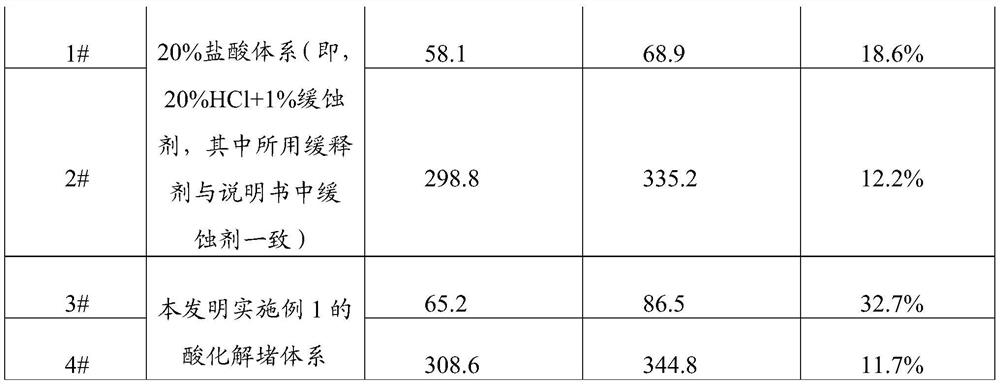

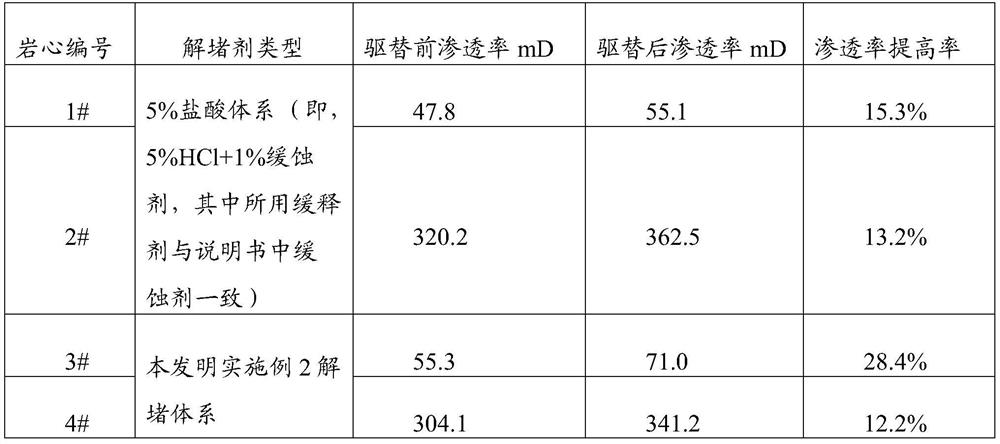

Embodiment 2

[0067] The preparation of the W / O / W type multiple emulsion acidification plugging removal system of this application includes the following steps:

[0068] (1) Oil phase preparation: the surfactant Span60 and hydrophobic nano-silica particles are dissolved in the oil by ultrasonic dispersion to obtain an oil phase; wherein, based on the total mass of the oil phase obtained, the mass fraction of Span60 is 1% 1. The mass fraction of the hydrophobic nano-silica particles is 0.3%, and the particle diameter of the hydrophobic nano-silica particles is 30nm; the oil is styrene tar;

[0069] (2) Preparation of internal water phase: based on the total mass of the internal water phase obtained, the mass fraction is 5% hydrochloric acid, 2% corrosion inhibitor and 2% hydroxyethylidene diphosphonic acid dissolved in water to obtain internal water Phase, wherein, the hydrochloric acid is prepared by diluting with 38% analytically pure hydrochloric acid, the corrosion inhibitor is a commerc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com