Power transmission system

A technology of power transmission and power input shaft, applied in transmission, fluid transmission, belt/chain/gear, etc., can solve problems such as waste of environment, emission, impact on engine life and efficiency, and achieve good load response and efficient utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

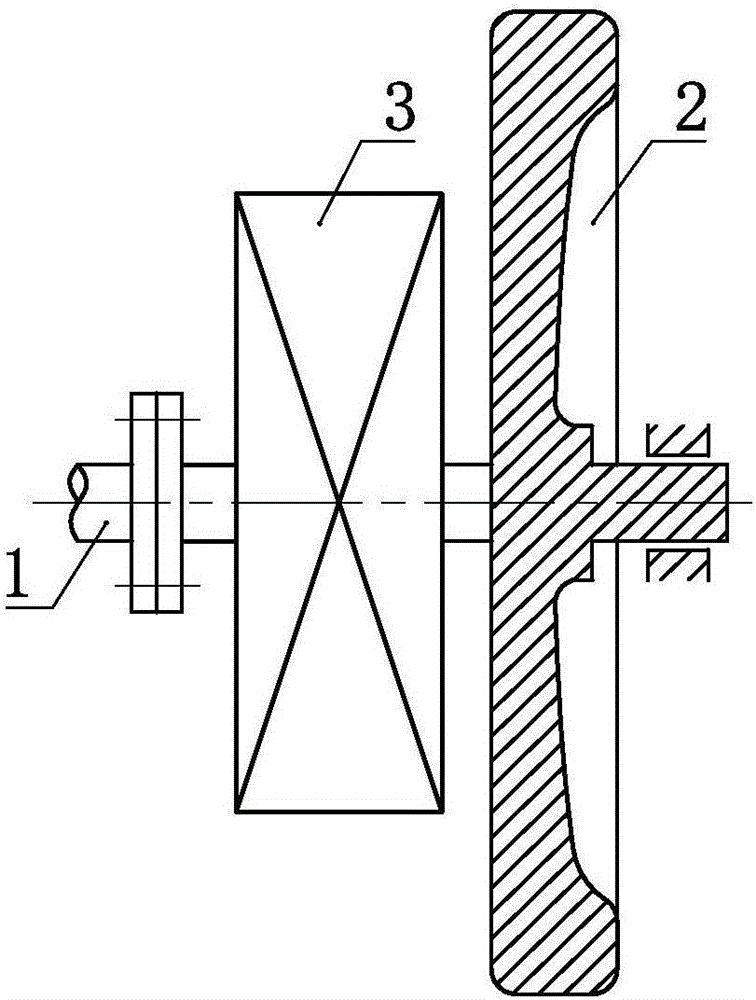

[0047] A power transmission system such as figure 1 As shown, a power input shaft 1 and a flywheel 2 are included, and the power input shaft 1 and the flywheel 2 are set through a transmission ratio device 3 .

[0048] As a convertible implementation mode, in Embodiment 1 of the present invention, the variable ratio device 3 can be further selectively selected as a fluid variable ratio device, an electromagnetic variable ratio device, or a mechanical variable ratio device. Furthermore, the variable ratio device 3 can be further selectively configured as a mechanical continuously variable transmission device.

Embodiment 2

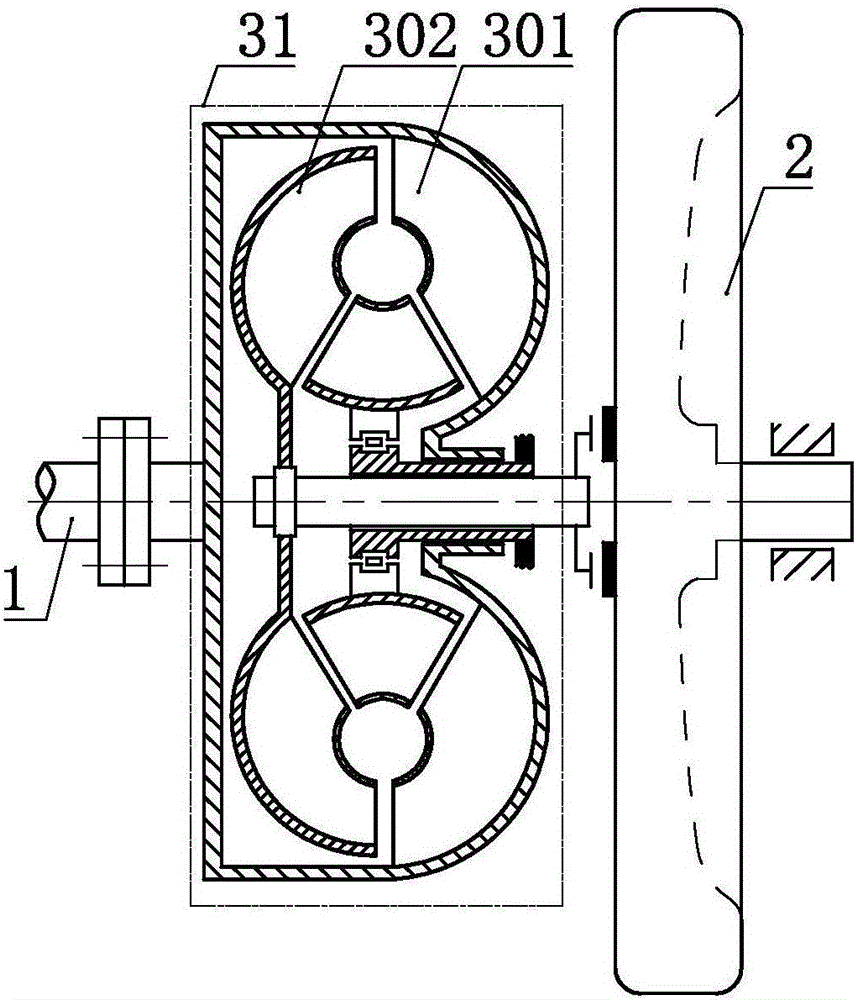

[0050] A power transmission system such as Figure 2.1 and 2.2 As shown, on the basis of Embodiment 1, the ratio ratio device 3 is further set as a fluid torque converter 31, and the power input shaft 1 is fixedly connected to the pump wheel 301 of the fluid torque converter 31. The flywheel 2 and the turbine 302 of the fluid torque converter 31 are arranged in clutch transmission.

[0051]As a convertible implementation, in Embodiment 2 of the present invention, the power input shaft 1 and the pump wheel 301 of the fluid torque converter 31 can also be selectively arranged in an integrated, transmission or clutch transmission; and / or Or, selectively choose to make the flywheel 2 and the turbine 302 of the fluid torque converter 31 be arranged in transmission, fixed connection or integrated.

[0052] As a transformable embodiment, the embodiment 2 and its transformable embodiments can further selectively choose to make the pump wheel 301 as axial flow or radial flow; and / or ...

Embodiment 3

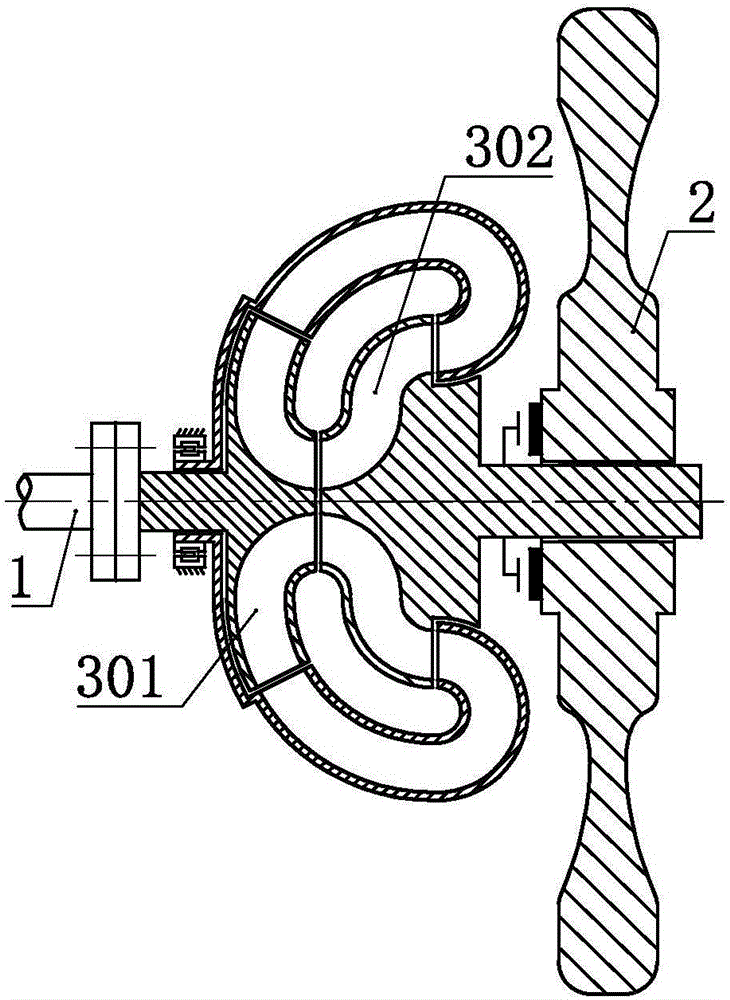

[0055] A power transmission system such as image 3 As shown, on the basis of Embodiment 1, the ratio ratio device 3 is further set as a fluid torque converter 31, and the fluid torque converter 31 is set as a displacement type hydraulic torque converter, and the displacement type hydraulic torque converter The torque converter includes a displacement fluid pump 7 and a displacement fluid motor 8, the displacement fluid pump 7 is fixedly connected to the power input shaft 1, and the displacement fluid motor 8 is connected to the flywheel 2 for clutch transmission. .

[0056] As a changeable implementation mode, in Embodiment 3 of the present invention, the positive displacement fluid pump 7 and the power input shaft 1 can also be selected to be integrated, driven or clutched; and / or further selected Optionally, the volumetric fluid motor 8 and the flywheel 2 are fixedly connected, integrated or transmitted.

[0057] As a transformable embodiment, the volume-type hydraulic to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com