Energy-saving method for successive heating and successive stopping of heating in tunnel furnace

A technology of stopping heating and sequential heating, which is applied in the field of sequential heating in tunnel furnaces and energy-saving by sequential stopping of heating, which can solve the problems of long heating time, large energy consumption and energy waste in tunnel furnaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific examples are given and described in detail as follows.

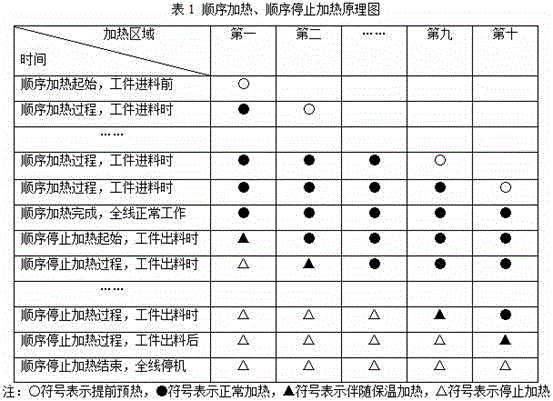

[0016] Please refer to Table 1, an energy-saving method for sequentially heating and sequentially stopping heating of a tunnel furnace, including the following steps:

[0017] S1. In the tunnel furnace, set up at least three independently working heating areas along its length, that is, each heating area is equipped with an independently working heating device, such as an electric heating tube;

[0018] S2. Start the tunnel furnace. Before the workpiece enters each heating zone in turn, control at least one heating zone close to the workpiece to preheat in advance as the preheating zone in advance; and when the workpiece reaches the corresponding preheating zone in advance, the preheating zone in advance The heating area reaches the set temperature; and so on, realize sequential heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com