Device and method for detecting interior trim conveying line drive rack

A detection device and conveying line technology, applied in mechanical measuring devices, measuring devices, using mechanical devices, etc., can solve the problems of dimensional accuracy consistency cannot be effectively guaranteed, accuracy cannot be effectively guaranteed, and can solve the problem of on-site installation. The effect of debugging, stable welding quality and stable dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

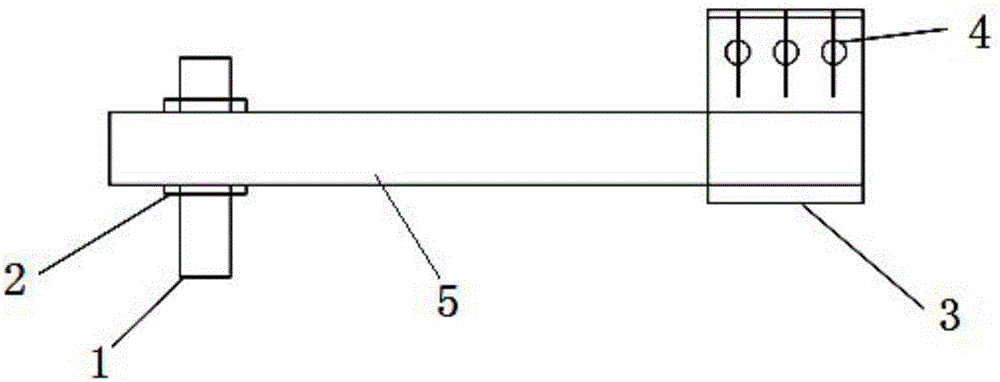

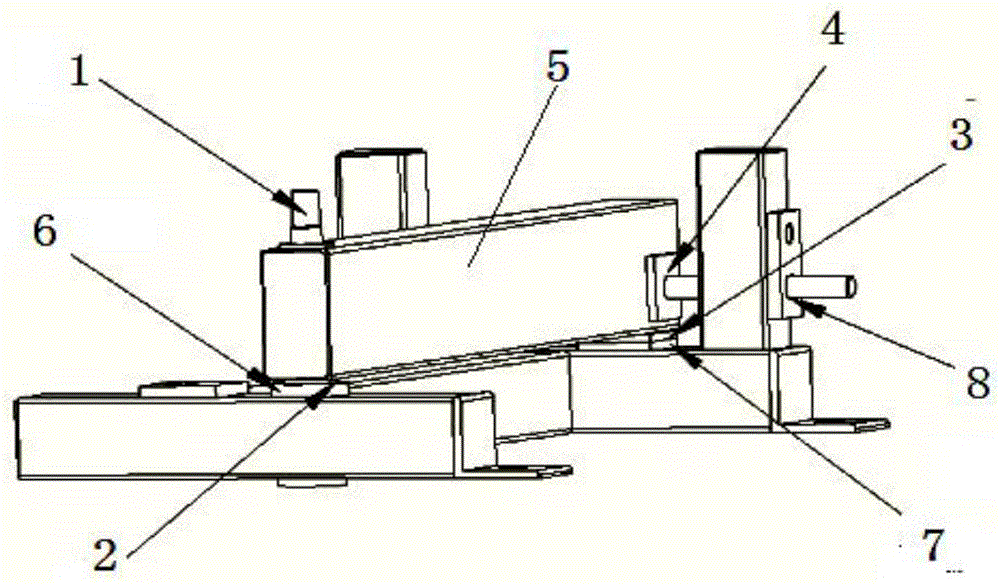

[0020] A frame detection device driven by an interior conveying line, which is composed of a horizontal frame plate 5, a guide sleeve detection shaft 1, a frame end face detection surface 2, a frame nylon block detection surface 3, and a detection tool plate hole 4. One end of the plate is vertically fitted with the detection shaft of the guide sleeve, and the detection shaft of the guide sleeve protrudes from the lower end of the horizontal frame plate. The bottom surface of one end is made with a testing surface of a nylon block of a frame, and a hole of a checking tool plate is fixed on the upper part of the testing surface of the nylon block of the frame, and a plurality of testing holes are formed on the holes of the checking tool plate. The axis cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com