Method for predicting hot-spot temperature of transformer winding under low temperature

A technology of transformer winding and hot spot temperature, which is applied to thermometers, thermometers and instruments using electrical/magnetic components directly sensitive to heat, etc., can solve the problems of no transformer heat exchange process, temperature rise, etc., to improve safety and reliability. The effect of stability, hot spot temperature prediction is accurate and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] see figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , a method for predicting the hot spot temperature of transformer windings under low temperature conditions (-20°C to 0°C), comprising the following steps:

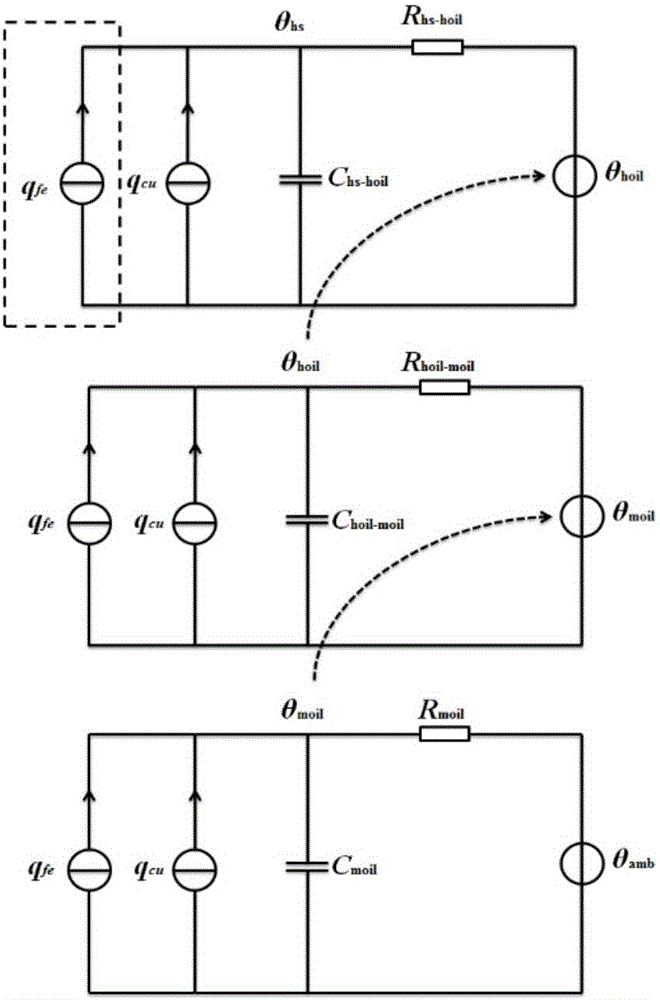

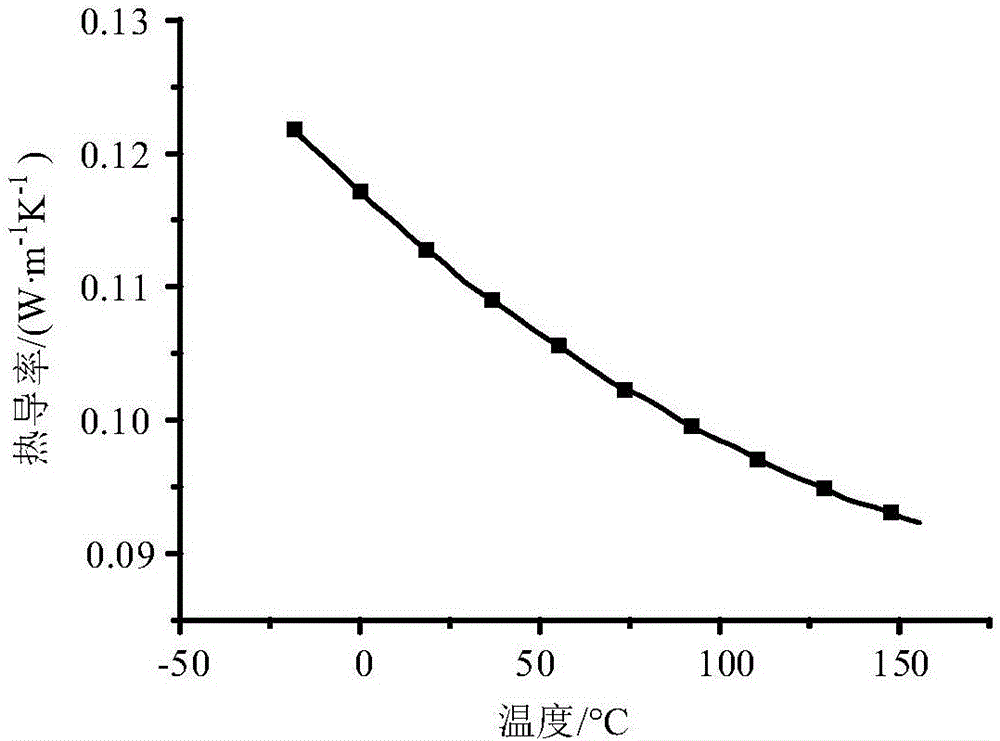

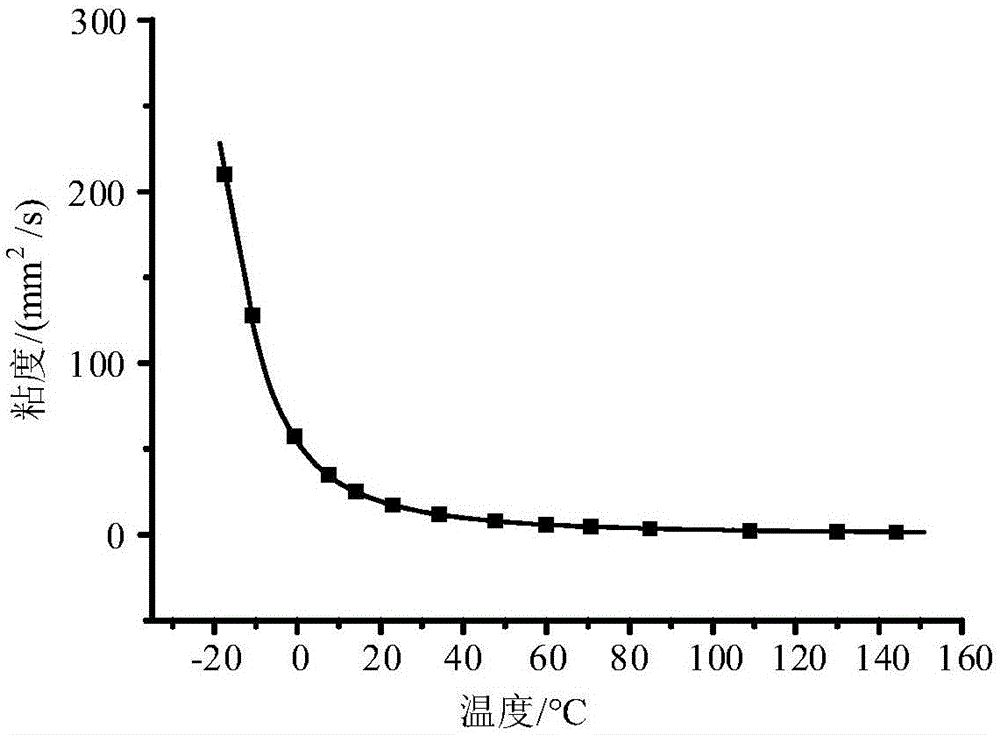

[0037] a. Since the nonlinear thermal resistance of the oil in the thermal circuit model is related to the density, viscosity, thermal conductivity, and specific heat capacity of the transformer oil, the change rule of the density, viscosity, thermal conductivity, and specific heat capacity of the transformer oil with temperature is measured and calculated. This law calculates the thermal resistance of transformer oil. The invention considers the influence of low temperature on the density, viscosity, specific heat capacity and thermal conductivity of transformer oil. The density, viscosity, specific heat capaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com