Combined electric appliance flange glue filling sealing detection method

A technology for sealing detection and combination electrical appliances, which can be applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

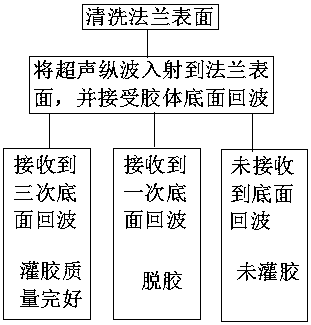

[0032] Such as figure 1 As shown: this embodiment provides a method for detecting the glue filling and sealing of the flange of a combined electrical appliance, including the following steps:

[0033] S1. Clean the surface of the flange to ensure that the surface of the flange on which the ultrasonic longitudinal wave will be incident is a plane;

[0034] S2. Inject the ultrasonic longitudinal wave into the cleaned flange surface, and accept the colloidal bottom surface echo;

[0035] S3. Judging the construction quality of glue filling by the echo of the bottom surface of the colloid. When the quality of the glue filling is intact, there will be three colloid bottom surface echoes; in the case of degumming, there will be one colloid bottom surface echo, and the echo height will be reduced. To 40%-60%; in the case of unfilled, no colloidal back-wall echo will be produced.

[0036] Generally, in a homogeneous material, the existence of defects will cause the discontinuity of ...

Embodiment 2

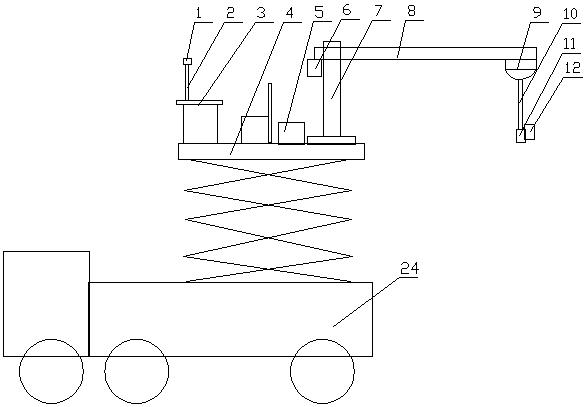

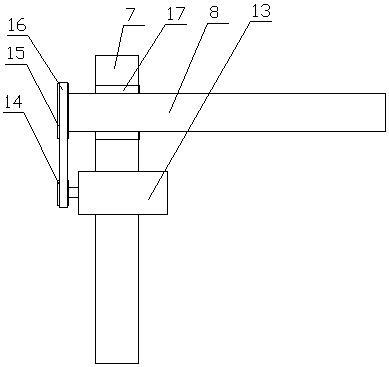

[0062] Such as figure 2 and image 3 As shown: this embodiment provides a high-voltage combined electrical appliance flange glue sealing detection device, including a base 24, a lifting platform 4 is set on the base 24, and a lifting rod 7 is installed on the lifting platform 4 to rotate. The top of the rod 7 is provided with a cross arm 8 through the rotation mechanism 6, and the front end of the cross arm 8 is provided with a two-axis cloud platform 9, the direction of the two-axis cloud platform 9 is perpendicular to the axis of the cross arm 8, and the two-axis cloud platform The top of the table 9 is provided with a first telescopic rod 10, and the front end of the first telescopic rod 10 is provided with an ultrasonic sensor 11, and a vertical calibration mechanism 12 is provided on the ultrasonic sensor 11, and a controller 3, an ultrasonic Generator 5, oscilloscope 2, alarm 1, described ultrasonic sensor 11, ultrasonic generator 5, controller 3, alarm 1 are connected...

Embodiment 3

[0068] Such as Figure 5 Shown: its difference with embodiment two is:

[0069] The second telescopic link 20 is also set on the two-axis platform 9, and the electric grinding mechanism is arranged at the front end of the second telescopic link 20. Sandpaper 23 provided on the surface of disc 22. Because the surface of the flange has been exposed to the air for a long time, although it is protected by a paint layer, it cannot be guaranteed that the surface is free of rust or debris. Therefore, the surface of the flange is cleaned by an electric grinding mechanism before ultrasonic testing to ensure that the surface is clean. plane, will not affect the detection results. The electric grinding mechanism includes a grinding motor that drives the rotating disk at the front end to rotate, thereby driving the sandpaper on the rotating disk to rotate to achieve grinding. After the detection position is determined during use, the second telescopic rod is aligned with the position th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com