Functional cable magnetic snap

A multi-functional and cable technology, applied in the field of cable magnetic buckle, can solve the problems of difficult adaptation, incompatibility, limited promotion and application, etc., and achieve the effects of low manufacturing cost, easy operation and wide versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

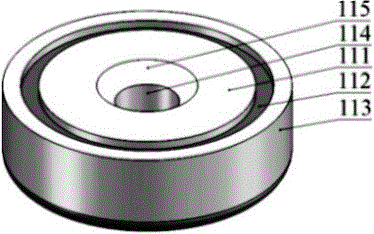

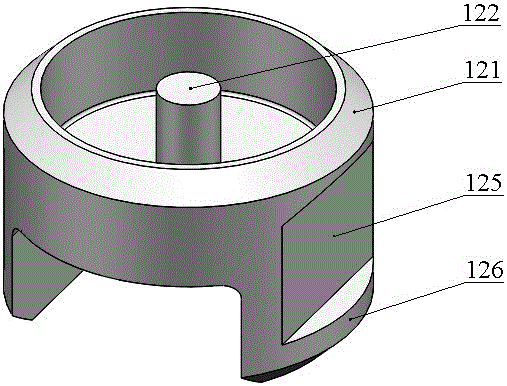

[0017] exist Figure 1-10 In the shown embodiment, the present invention is mainly composed of two components, an inner fastener (1) and an outer fastener (2). The inner fastener is mainly composed of a pot magnet (11) and a non-magnetic inner fastener (12). The fastener is mainly composed of a magnetic conductor (21) and a non-magnetic outer buckle (22). Among them: the pot magnet is a cylindrical structure, and its structural components mainly include a permanent magnetic column (111), a non-magnetic ring (112) and a magnetic pot (113) from the inside to the outside. The annular gap between the permanent magnetic post and the magnetic pot passes through Glue is injected to form a non-magnetic ring; a through hole (114) for penetrating the fastening connector is provided in the center, and a counterbore (115) is provided at the end of the through hole near the pot mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com