Mulch slitting mechanism with accurate mulch cut-off function for mulch applicator

A laminating machine, precise technology, applied in plant protection cover, botany equipment and method, gardening, etc., can solve time-consuming and labor-intensive problems, and achieve the effect of convenient use, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

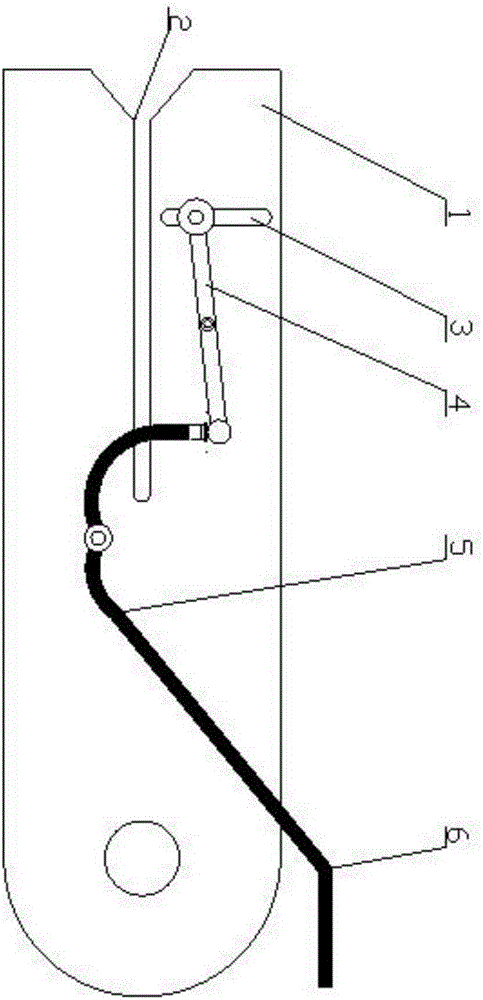

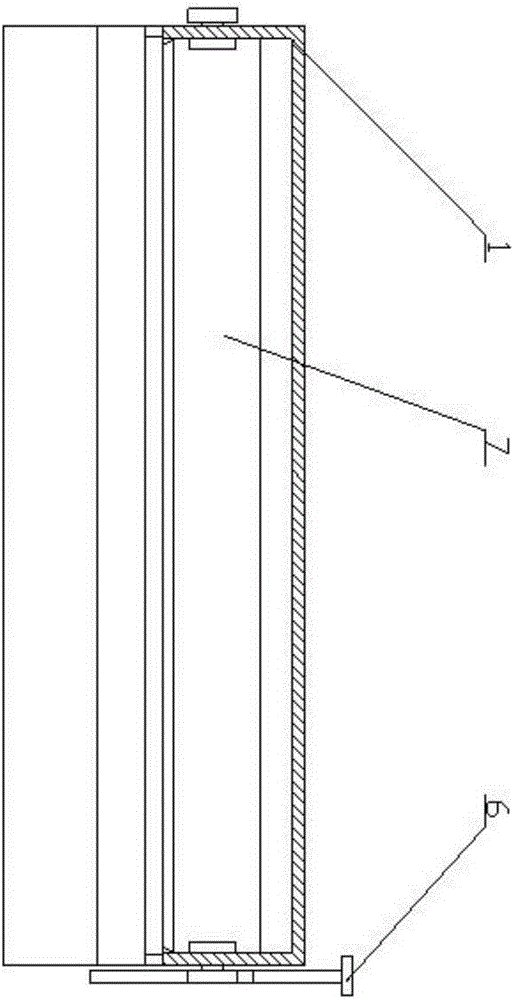

[0012] A film cutting mechanism of a film laminating machine capable of precisely cutting films, comprising a casing 1, a film outlet 2, a chute 3, a driving lever 4, a bending lever 5, a pedal 6, and a blade 7.

[0013] like figure 1 , figure 2 As shown, the shell 1 is a double-layer structure, and one side thereof is a film outlet 2, and one side of the shell 1 is provided with a film inlet, and the two ends of one side of the film inlet are respectively provided with connectors, so The above shell 1, its upper layer is a hollow structure, and the above shell 1 is specifically a C-shaped structure, and its two sides are respectively provided with chute 3, and the above shell 1, the two ends of the inner wall of its superstructure are respectively provided with The card slot, the blade 7 is arranged inside the upper layer of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com