All-sealed corrugated board carriage

A corrugated board, fully sealed technology, applied to vehicle parts, upper structure of trucks, upper structure, etc., can solve problems such as burn-through, difficulty in achieving high-efficiency operations in large quantities, and poor surface quality of CO2 shielded welding. To achieve the effect of ensuring full sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

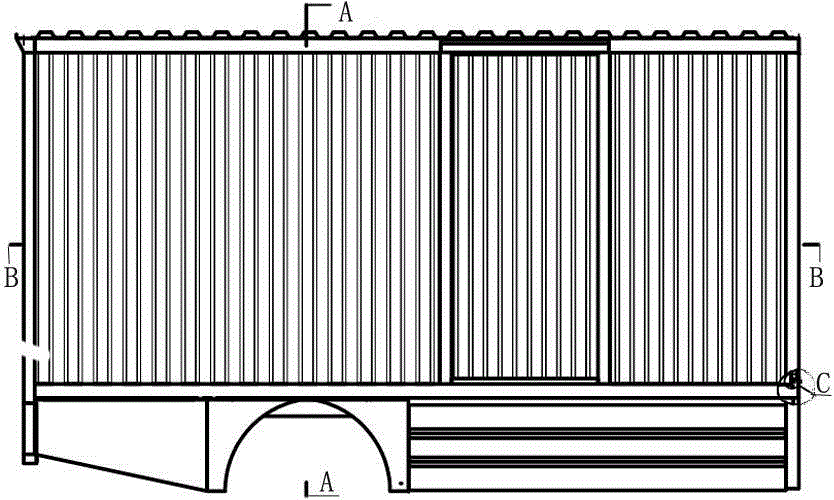

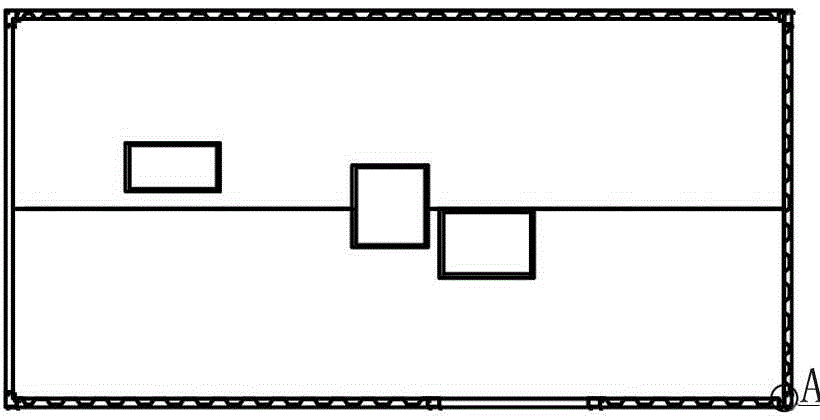

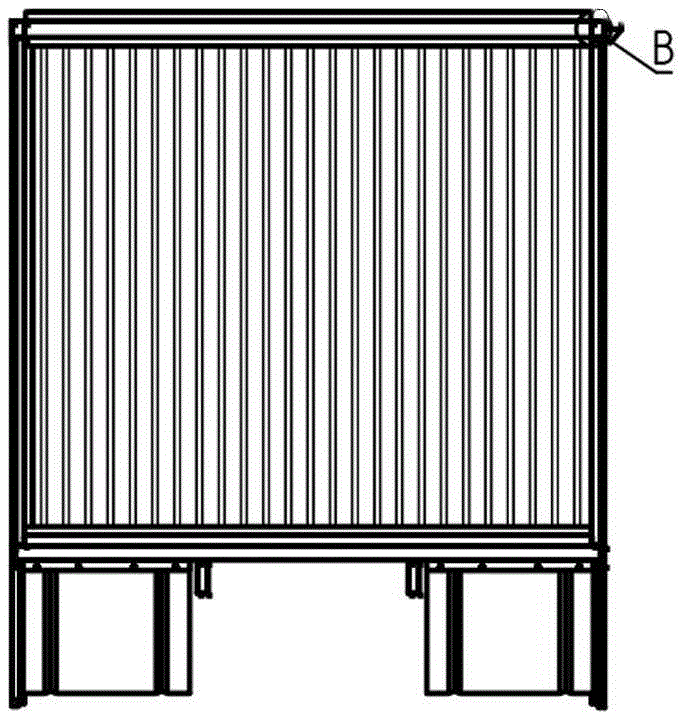

[0023] The present invention as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9.

[0024] A fully-sealed corrugated board compartment, including a corrugated board 3, the corrugated board 3 and the side wall front pillar 1, the corrugated board 3 and the front wall pillar 2 are respectively lapped and suspended by double-bending members 10 and welded into one body; the corrugated board 3 The right-angle inner gusset member 4 and the side wall upper beam 5 are overlapped for suspension spot welding, and the side wall upper beam 5 is suspended and spot welded outside the side wall upper beam 5 to make it integrated; the corrugated board 3 and the bottom plate front beam 8 1. The lower beam 9 of the dash 9 is integrated with the overlapping suspension spot welding of the base plate 7 through the labyrinth member 11, and finally becomes a fully sealed corrugated board compartment.

[0025] A suspension spot welding sealant is laid between the overlapping components of the corrugated board 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com