Beverage ingredient storage container with piston dynamic piercing outlet

A technology for beverage ingredients and storage containers, which is applied in the field of beverage ingredient storage containers, can solve the problems of not involving liquid ingredients, weakened pressure, inconsistent products, etc., so as to avoid taste influence and cross-contamination, prevent splashing, and prevent turbulent flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

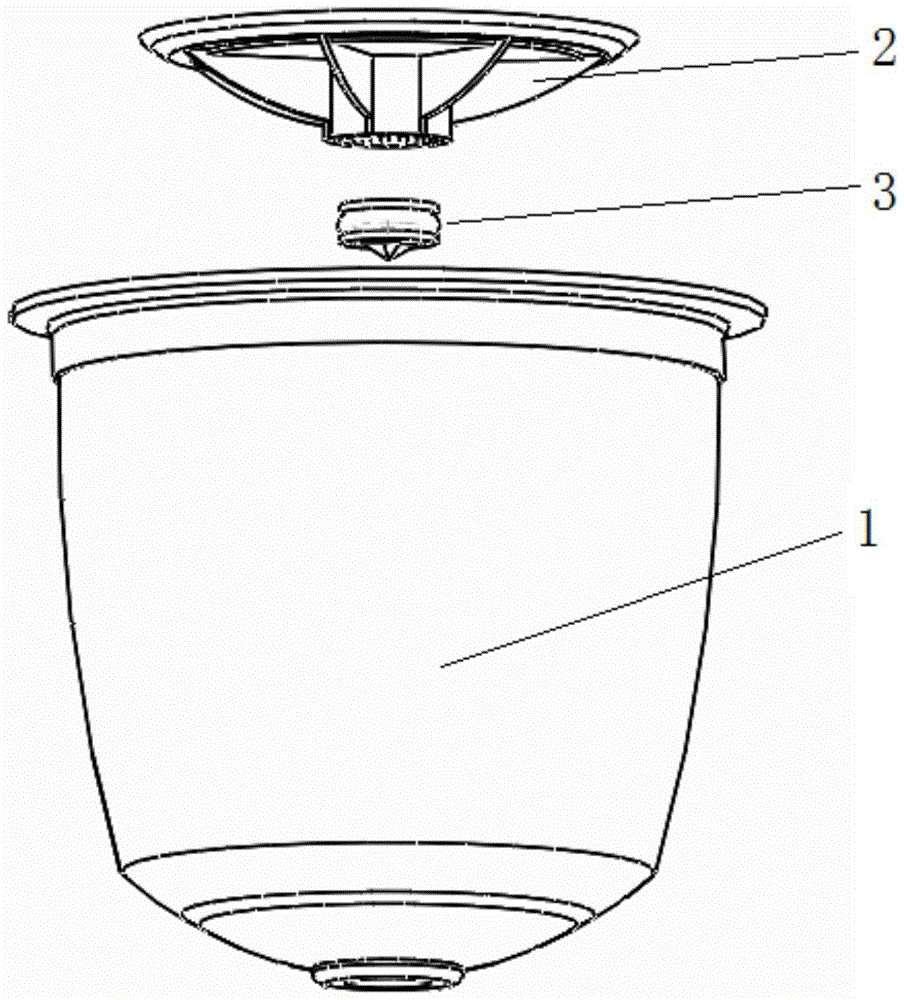

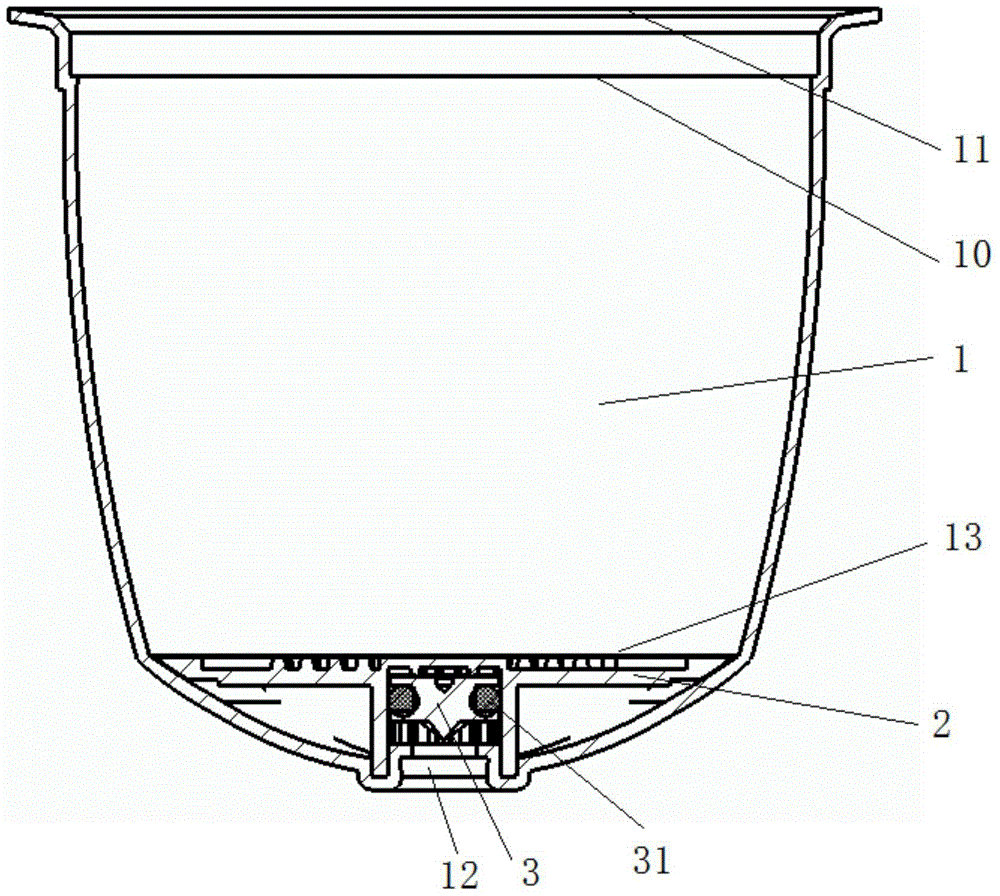

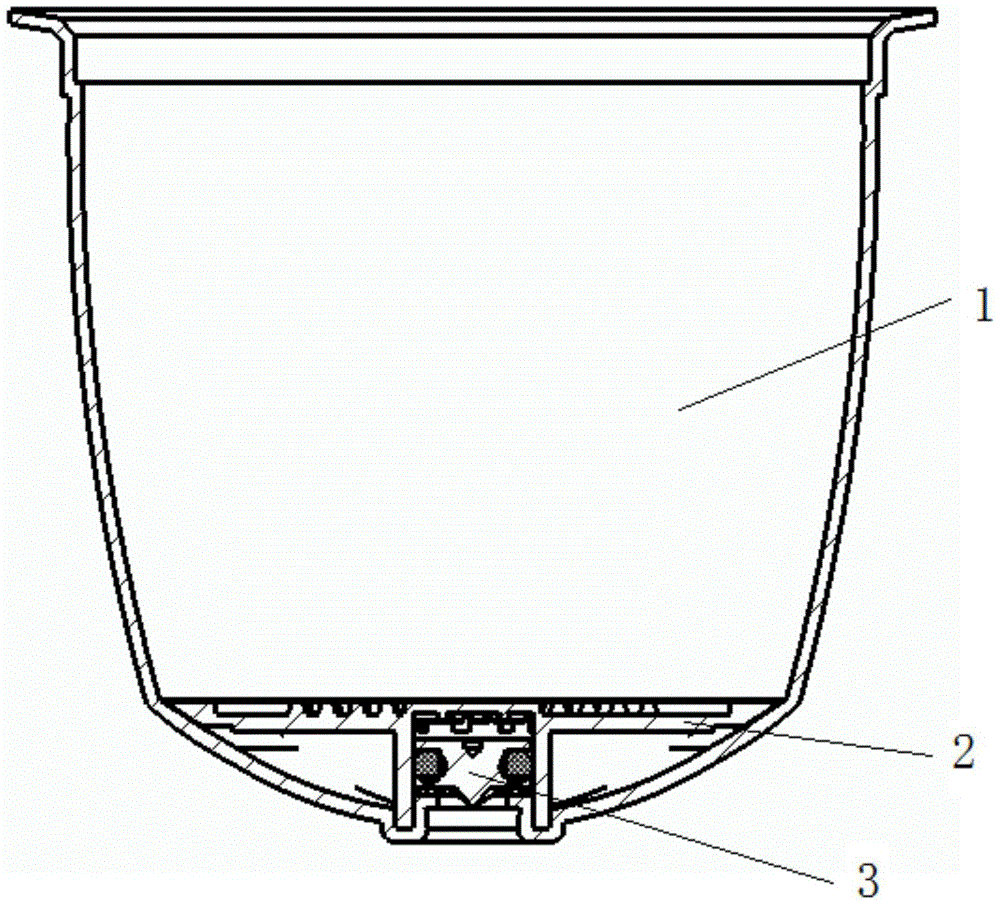

[0043] Such as Figure 1 to Figure 6 As shown, the beverage ingredient storage container with the dynamic puncture outlet of the piston includes an ingredient container 1, a deflector 2 and a piston body 3, and the deflector 2 and the piston body 3 are both located inside the ingredient container 1; Described batching container 1 comprises the upper end opening 11, the lower end opening 12 of composite film sealing respectively, and the size of described upper end opening 11 is greater than the size of described lower end opening 12; The upper filter membrane 10 and the lower filter membrane 13 of the middle and lower parts, a material bin filled with beverage ingredients is formed between the lower filter membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com