Flow amplifying valve and loading machine variable steering hydraulic system

A flow amplification and flow control valve technology, which is applied in the direction of fluid pressure actuators, mechanical equipment, servo motors, etc., can solve the problem that the flow amplification valve cannot directly use the variable hydraulic system, so as to improve the self-protection ability and simplify the hydraulic system , Improve the effect of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

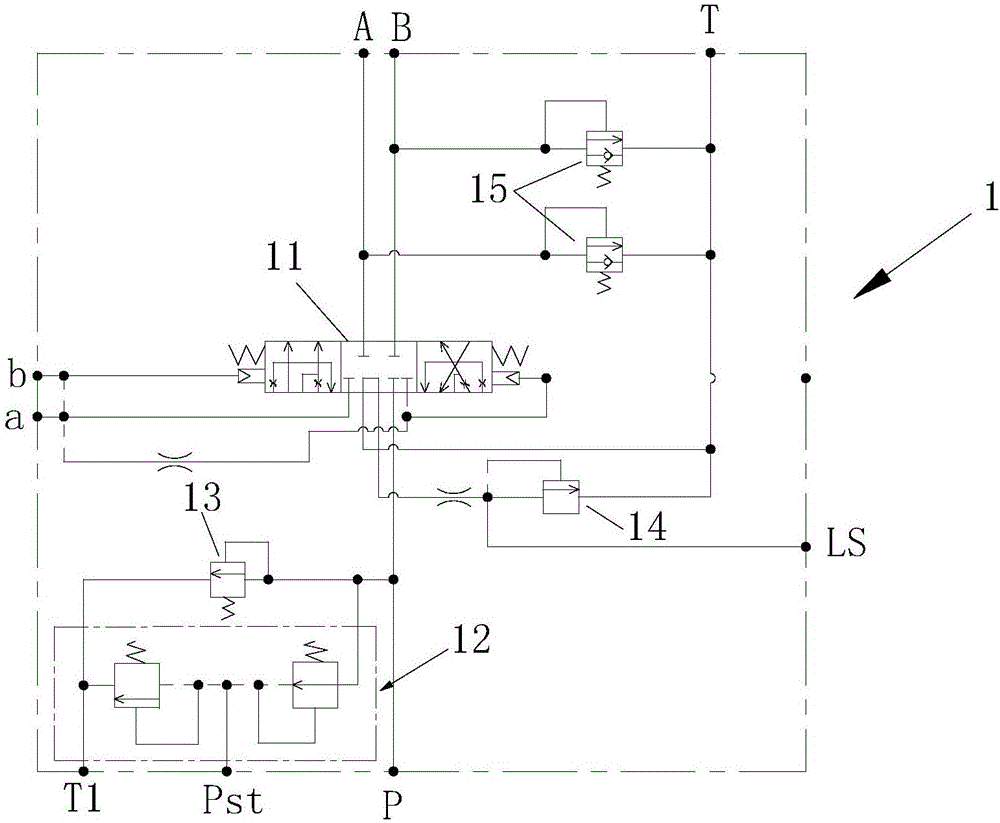

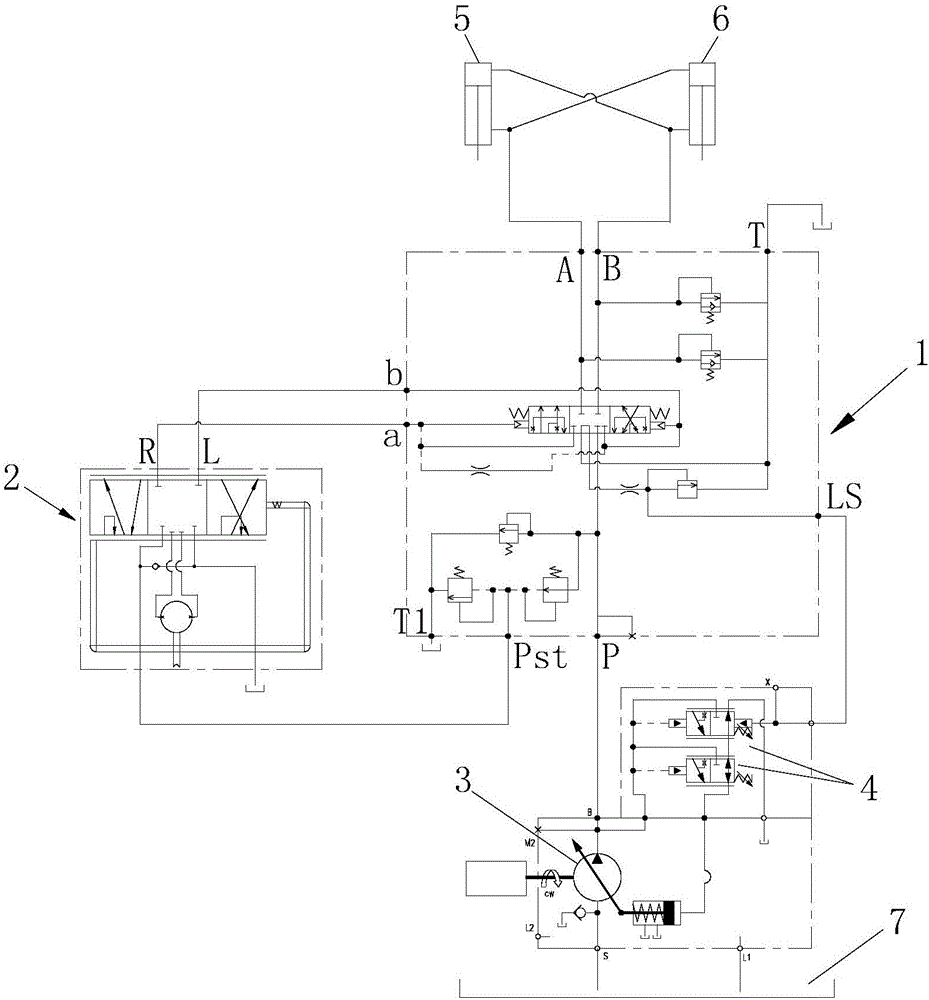

[0027] Such as figure 1 As shown, a flow amplifying valve includes a connected flow control valve 11 and a pilot oil supply module 12. For the convenience of description, the flow amplifying valve is used as figure 1 The big dotted line box in the periphery indicates that the pilot oil supply module 12 is used figure 1 The small dotted line box in shows that the flow amplifying valve 1 also includes a first oil outlet A, a second oil outlet B, a first pilot oil port a, a second pilot oil port b and a third pilot oil port Pst, The first and second pilot oil ports and the first and second oil outlets are respectively connected to the flow control valve 11 , and the third pilot oil port Pst is connected to the pilot oil supply module 12 . The flow control valve 11 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com