Roller brake

A technology of brakes and rollers, which is applied in the direction of hydraulic brakes, brake actuators, gear transmission mechanisms, etc., can solve the problem that the controllable braking of belt conveyors cannot be realized, the idler rollers do not have a braking function, and the safety of equipment is reduced and other problems, to achieve the effects of small braking impact, reliable braking, and controllable braking acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

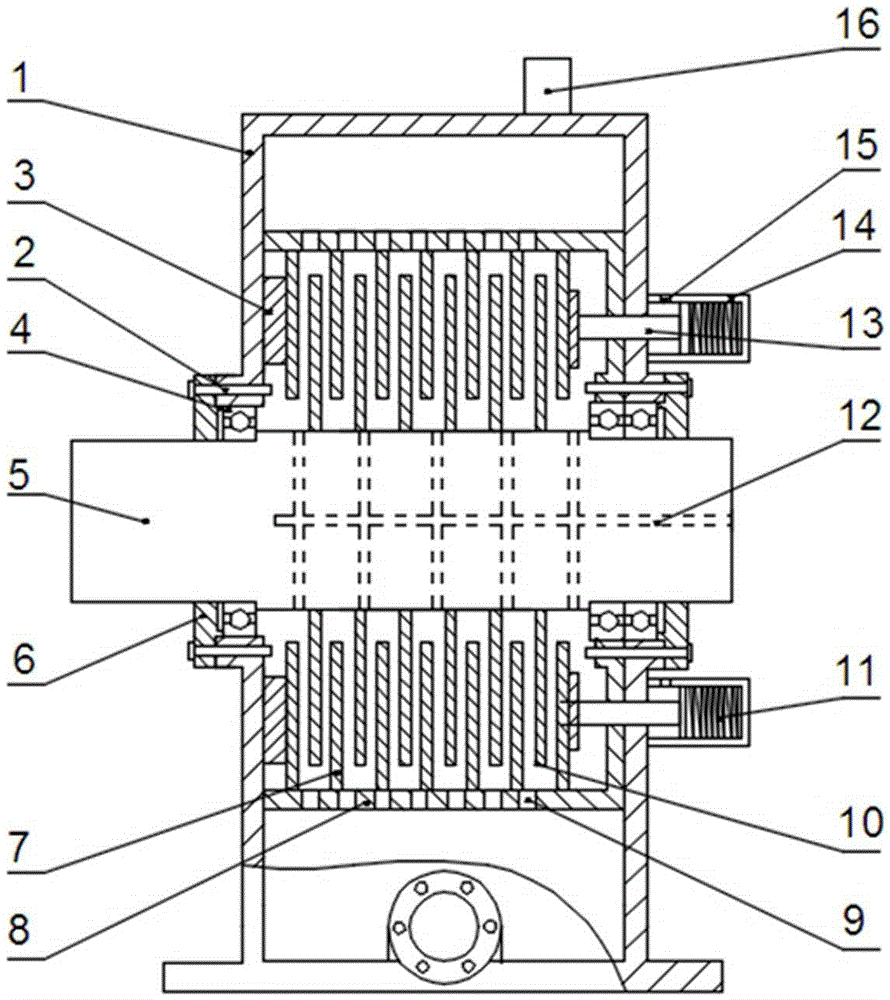

[0015] Roller brake, including box body, connecting bolts, backing plate, bearing, shaft, sealing cover, passive friction plate, passive drum, passive drum oil port, active friction plate, disc spring, brake oil passage, piston push rod, hydraulic red , Hydraulic red oil inlet and venting components.

[0016] The box is connected to the ground through anchor bolts; the brake oil passage is connected to the brake oil pump; the oil inlet of the hydraulic cylinder is connected to the control oil pump; the passive drum is connected to the box through bolts The two ends of the friction plate are made of powder metallurgy material, and oil grooves are arranged on it to facilitate the passage of brake oil and lubricate the cooling disc surface; the shaft is processed with axial oil passages and radial oil passages to make the brake oil It enters between the active and driven friction plates; a high-pressure sealing ring is installed between the sealing cover and the shaft to ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com