Optical fiber monitoring and checking system

A technology of optical fiber and judgment module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

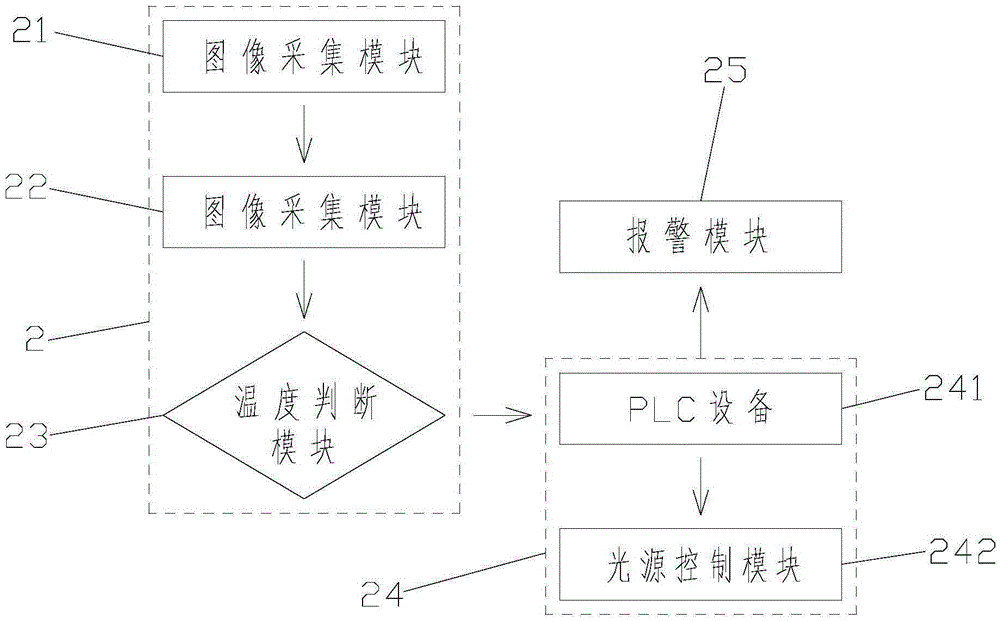

[0039] Embodiment 1: as attached figure 2 The shown optical fiber monitoring and breaking system includes: image acquisition module 21: used to collect image information within the monitoring range; image processing module 22: used to convert the collected image information into temperature distribution information; temperature judgment module 23: It is used to judge whether there is an abnormal temperature point exceeding the set value in the temperature distribution information; the signal control module 24: judges the alarm signal for transmitting the abnormal temperature point, and controls the switch state of the light source; the alarm module 25: judges the module or the signal control module according to the temperature The abnormal temperature information fed back will be sent to the police. When the temperature judging module 23 sends temperature abnormal point information to the signal control module 24 ; the temperature judging module 23 is disconnected from the al...

Embodiment 2

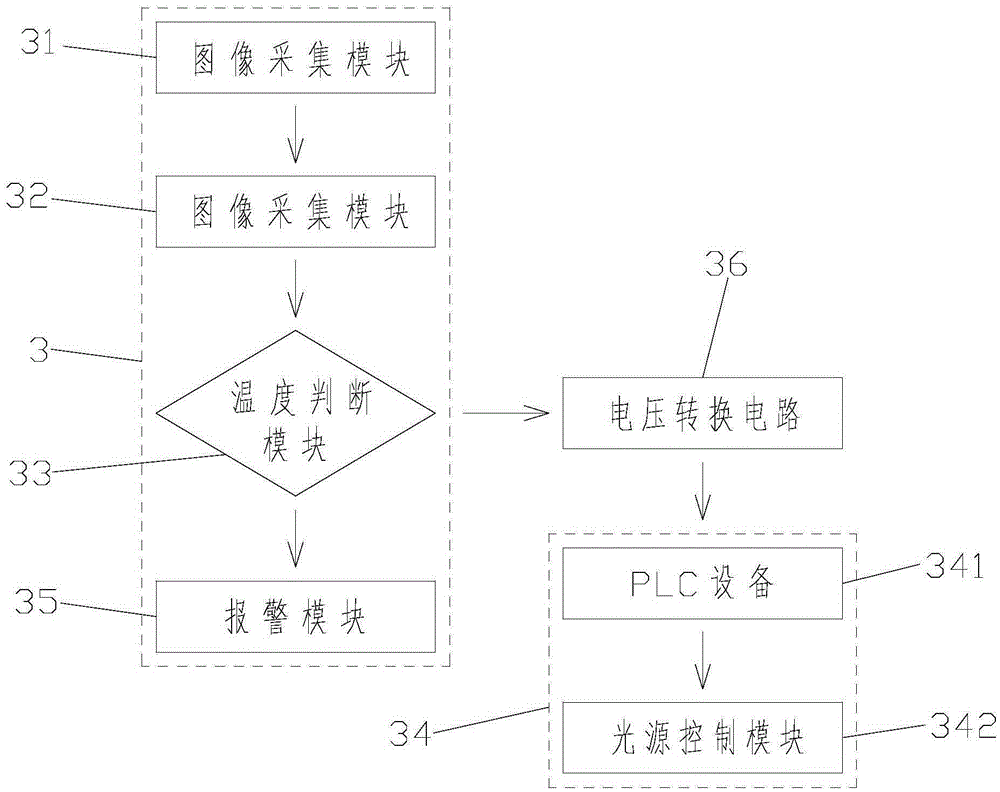

[0043] Embodiment 2: as attached image 3 The shown optical fiber monitoring and detection system includes: image acquisition module 31: used to collect image information within the monitoring range; image processing module 32: used to convert the collected image information into temperature distribution information; temperature judgment module 33: It is used to judge whether there is an abnormal temperature point exceeding the set value in the temperature distribution information; the signal control module 34: judges the alarm signal for transmitting the abnormal temperature point, and controls the switch state of the light source; the alarm module 35: judges the module or the signal control module according to the temperature The abnormal temperature information fed back will be sent to the police. When the temperature judging module 33 sends temperature abnormal point information to the alarm module 34 and the signal control module 35 , the signal control module 34 is disco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com