A processing die generation unit

A technology for generating units and processing molds, applied in simulators, instruments, computer control, etc., can solve problems such as manual input parameters are prone to errors, increase manufacturers' production costs, and have many defective products, so as to save time, cost and mistakes The effect of high rate, high accuracy and accurate characteristic parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

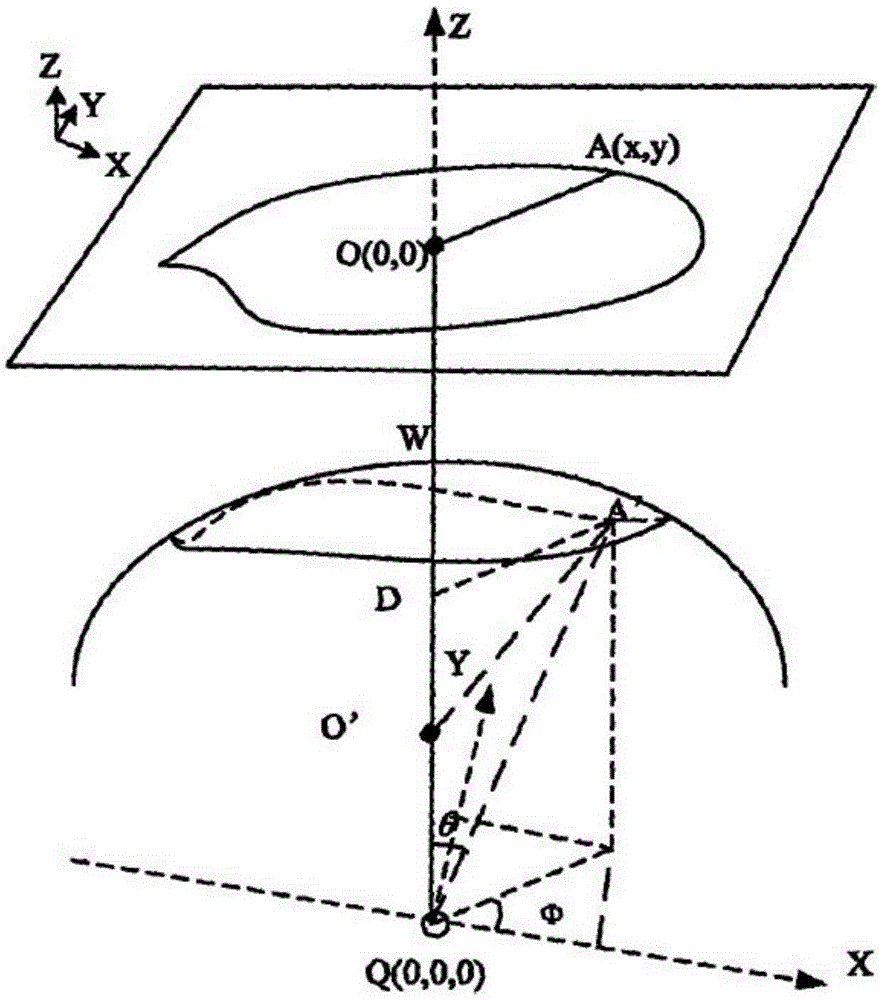

[0056] Scan graphics, orientation marks and other special marks on the first 2D drawing. Determine the direction mark of the 2D drawing, including radial mark, transverse mark and coordinate mark. Establish a three-dimensional space coordinate system according to the direction mark. Divide the graphics of a 2D drawing into several primitives. Use coordinates or functional equations to record the spatial area, shape and specific location of each primitive. Store the data information of each primitive in the primitive database. The database also includes a primitive database for classifying and storing primitives according to primitive types and coordinate areas.

[0057] Read graphics, orientation marks and other special marks on the second 2D drawing. If the second drawing belongs to the same plane as the first drawing, and the graphics are drawn in the same scale, use the coordinates or function equations of the same three-dimensional coordinate system to record the spati...

Embodiment 2

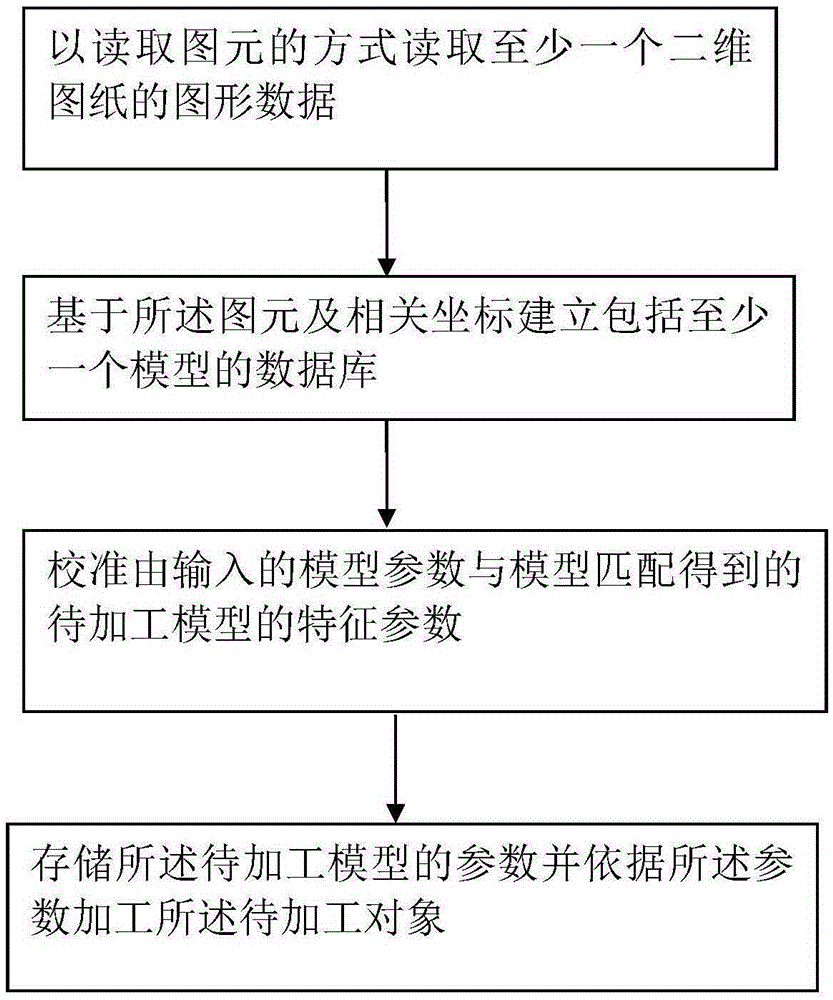

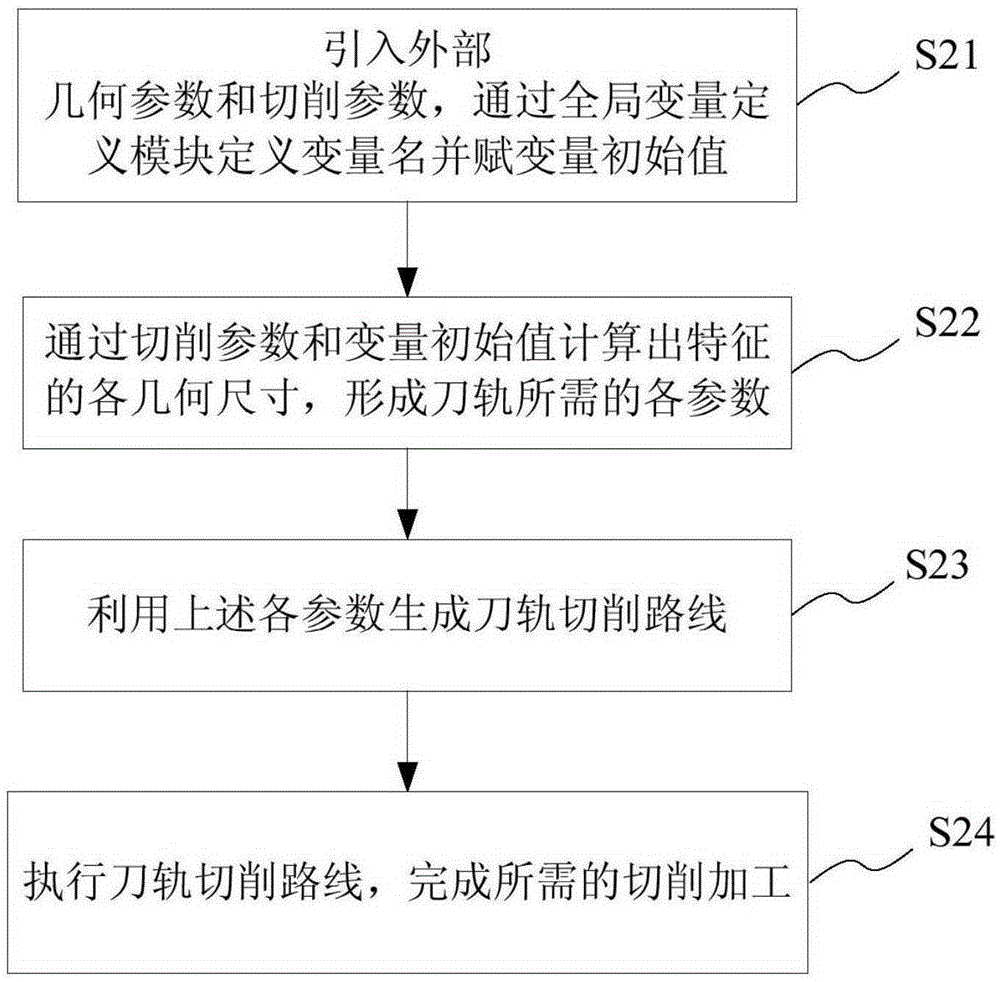

[0087] This embodiment also provides a device for parametrically processing objects based on multi-dimensional drawings, including a graphic input unit, a database unit, a coordinate conversion unit, a calibration unit, a storage unit, and a PLC-controlled processing unit. The graphic input unit reads graphic data of at least one two-dimensional drawing in the form of a graphic element. The database unit stores at least one model based on primitives and associated coordinates. The calibration unit calibrates the characteristic parameters of the model to be processed obtained by matching the input model parameters with the model. The storage unit stores the parameters of the model to be processed and enables the PLC to control the processing unit to process the object to be processed according to the parameters.

[0088] According to a preferred embodiment, the device further includes a coordinate transformation unit. The coordinate conversion unit establishes a three-dimensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com