A two-chamber double-layer support structure integrating positioning and centring functions

A support structure and centering technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of long switching time between atmosphere and vacuum, low equipment production capacity, etc., and achieve simple and reliable structure, low manufacturing cost, Accurate and reliable positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment, the present invention is further described in detail, but the protection content of the invention is not limited to described embodiment:

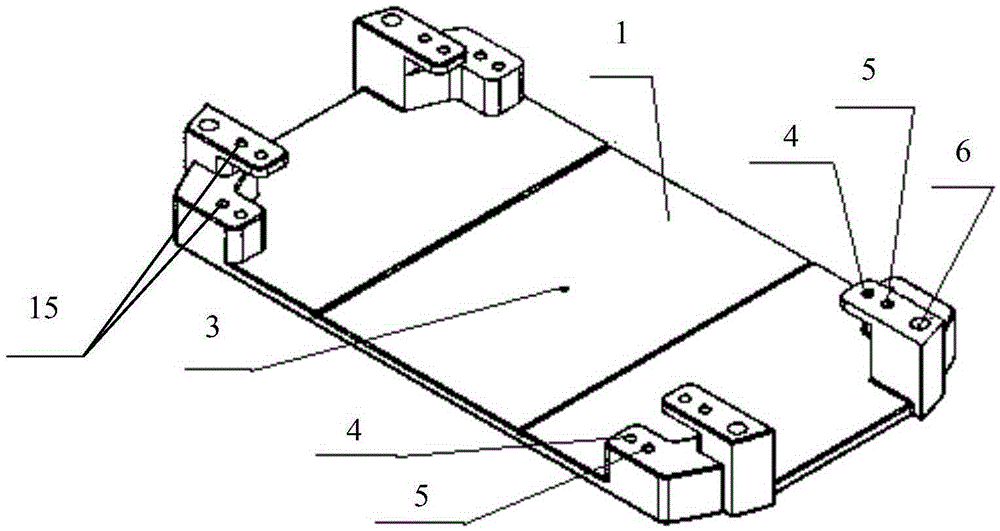

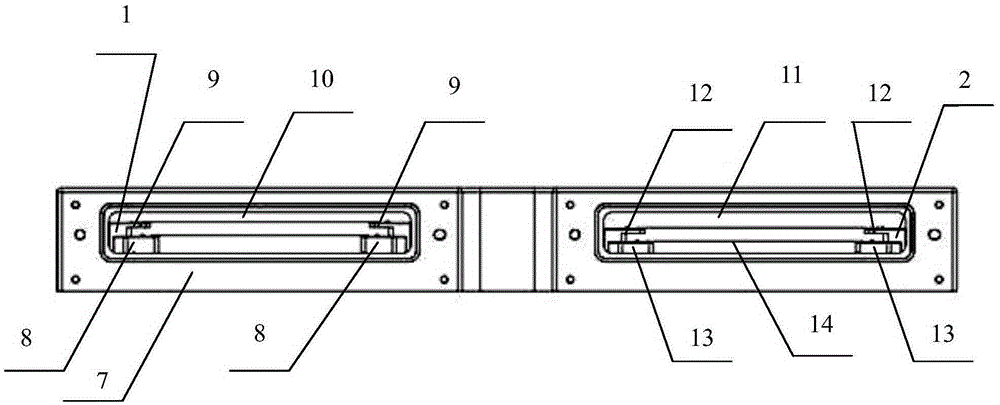

[0017] like Figure 1-2 As shown, a two-chamber double-layer support structure integrating positioning and centering functions, the support structure includes a high-level double-layer wafer support 1 and a low-level double-layer wafer support 2; the high-level double-layer wafer support 1. There is a high-level first layer 8 of a wafer support and a high-level second layer 9 of the wafer support. The low-level double-layer wafer support 2 is provided with a low-level first layer 12 of the wafer support and a low-level second layer 13 of the wafer support. ; The wafer support high first layer 8, the wafer support high second layer 9, the wafer support low first layer 12 and the wafer support low second layer 13 are respectively provided with sapphire balls 4 for supporting the wafer, The limiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com