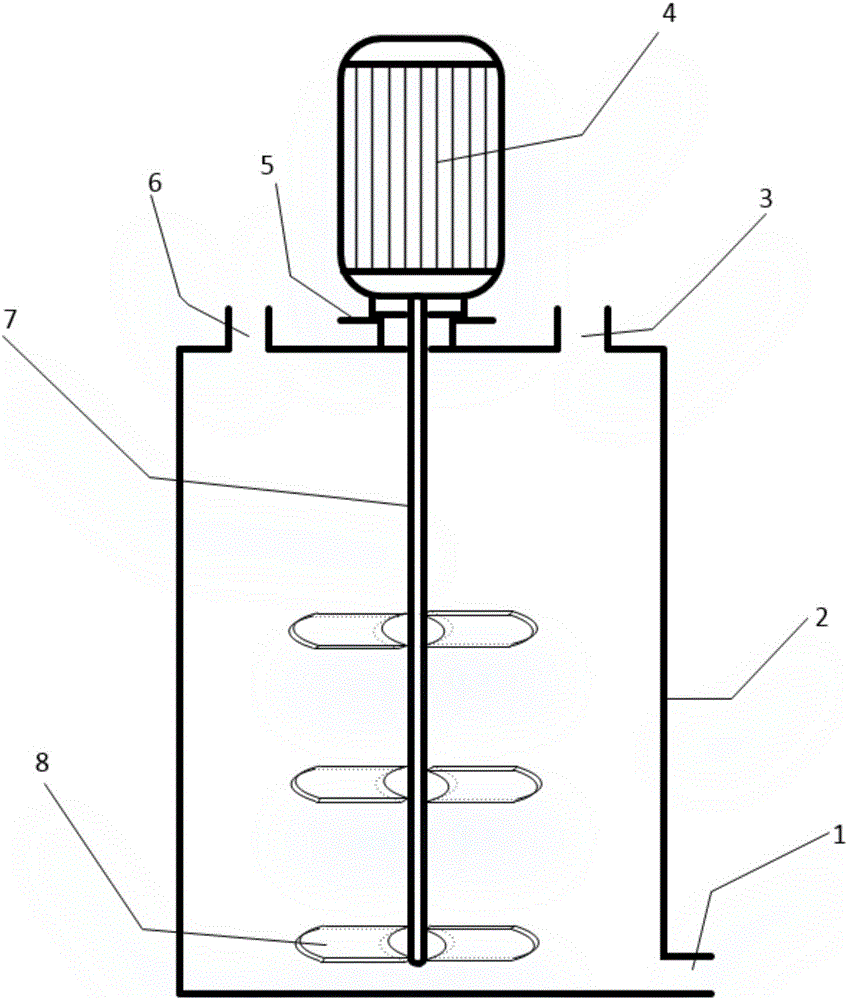

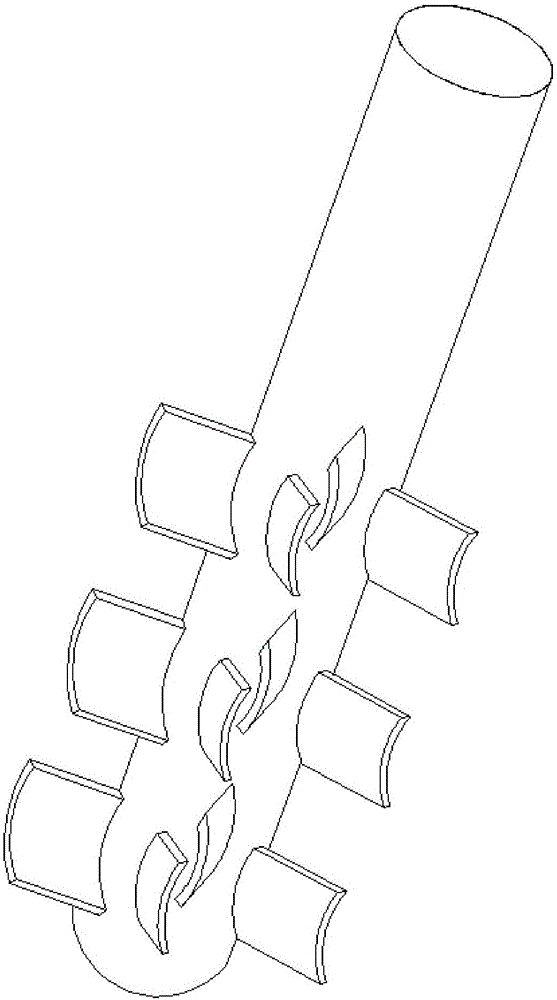

LED phosphor stirring device with multiple layers of vanes

A stirring device and phosphor powder technology, applied in mixers with rotating stirring devices, transportation and packaging, dissolving and other directions, can solve the problem of powder glue full of air bubbles, unfavorable uniform mixing of phosphor powder glue, and inability to guarantee the quality of LED lights, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiment of the present invention provides a multi-blade LED phosphor stirring device, which is used to solve the problem that the stirring blades of the traditional phosphor stirring device are all at the bottom of the stirring barrel, so it can only be stirred at the bottom of the barrel and on the upper layer of the container. The phosphor powder cannot be sufficiently stirred, which is not conducive to the uniform mixing of the phosphor glue, and the powder glue must be stirred in a vacuum environment. If the vacuum stirring effect is not good, the powder glue will be full of bubbles and the powder glue will also If the mixing is not sufficient, the quality of the LED lamp cannot be guaranteed.

[0028] In order to make the objectives, features, and advantages of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com