Water-based bi-component polyurethane finishing coat and preparation method thereof

A polyurethane topcoat, water-based two-component technology, applied in polyurea/polyurethane coatings, radiation-absorbing coatings, coatings, etc., can solve the problems of low gloss, poor weather resistance, poor water resistance, etc., and achieve simple operation and coating Layers for a smooth, high-gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

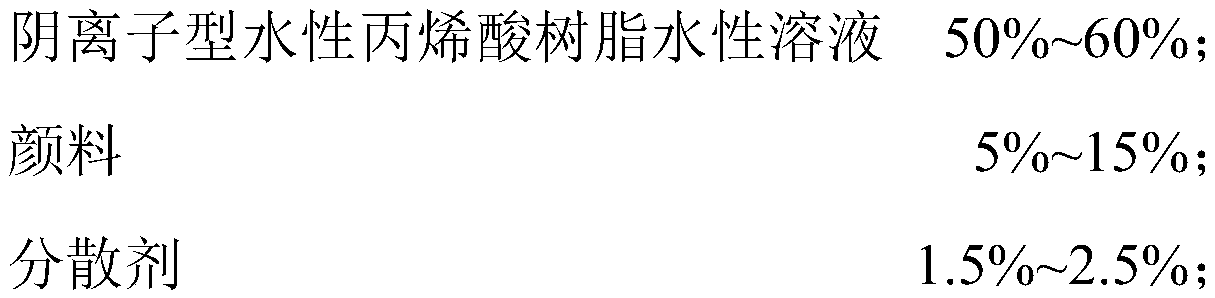

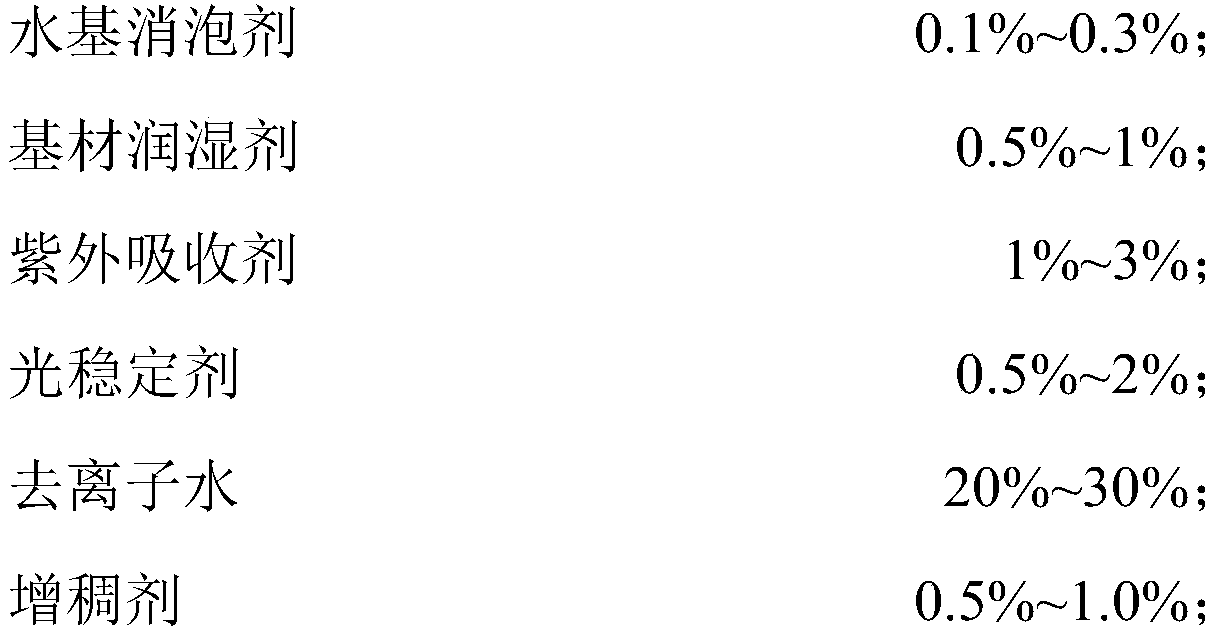

[0032] Embodiments of the present invention provide a water-based two-component polyurethane topcoat and a preparation method thereof, comprising the following raw materials in parts by weight:

[0033] A component:

[0034]

[0035] B component:

[0036] Polyisocyanate curing agent 10%.

[0037] Among them, the anionic water-based acrylic resin is the water-based hydroxyl acrylic resin Bayhydrol A145 of German Bayer Chemical and the water-based acrylic resin Maincote of American Dow Chemical. TM HG-54C is a mixture mixed in a mass ratio of 2:1, the pigment is TR92 from Huntsman in the United States, the dispersant is HLD-18 / AJ from Silcona in Germany, and the water-based defoamer is Surfynol MD-20 from Gas Chemical in the United States. The substrate wetting agent is C-600 from Silcona in Germany, the UV absorber is TINUVIN 1130 from BASF, the light stabilizer is TINUVIN 292 from BASF, the thickener is Tego 3010, and the polyisocyanate curing agent is N3390 from Bayer. ...

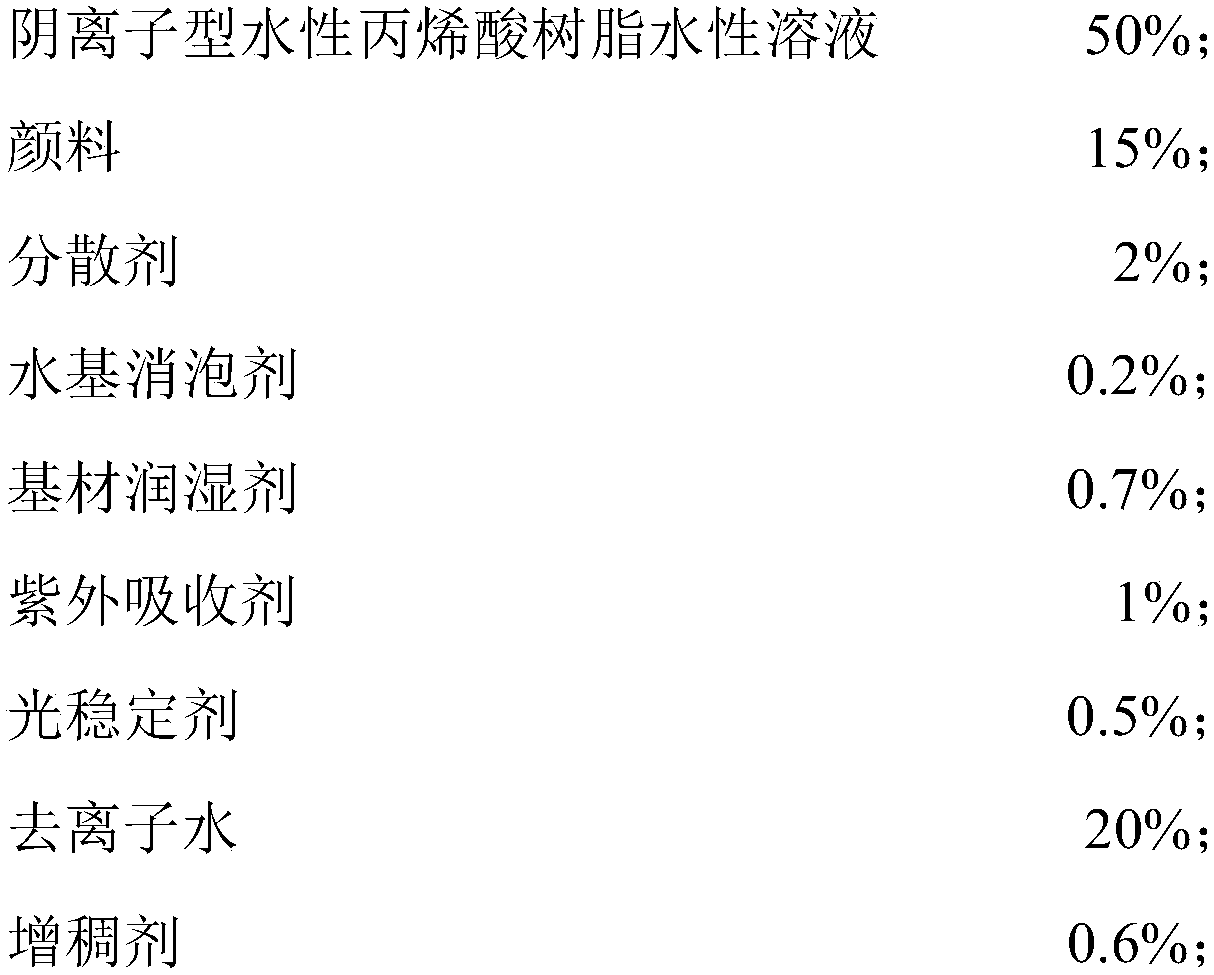

Embodiment 2

[0044] Embodiments of the present invention provide a water-based two-component polyurethane topcoat and a preparation method thereof, comprising the following raw materials in parts by weight:

[0045] A component:

[0046]

[0047] B component:

[0048] Polyisocyanate curing agent 15%.

[0049] Among them, the anionic water-based acrylic resin is the water-based hydroxyl acrylic resin Bayhydrol A145 of German Bayer Chemical and the water-based acrylic resin Maincote of American Dow Chemical. TM HG-54C is a mixture mixed in a mass ratio of 2.5:1, the pigment is TR92 from Huntsman in the United States, the dispersant is HLD-18 / AJ from Silcona in Germany, and the water-based defoamer is Surfynol MD-20 from Gas Chemical in the United States. The substrate wetting agent is C-600 from Silcona in Germany, the UV absorber is TINUVIN 1130 from BASF, the light stabilizer is TINUVIN 292 from BASF, the thickener is Tego 3010, and the polyisocyanate curing agent is N3390 from Bayer...

Embodiment 3

[0056] Embodiments of the present invention provide a water-based two-component polyurethane topcoat and a preparation method thereof, comprising the following raw materials in parts by weight:

[0057] A component:

[0058]

[0059]

[0060] B component:

[0061] Polyisocyanate curing agent 10%.

[0062] Among them, the anionic water-based acrylic resin is the water-based hydroxyl acrylic resin Bayhydrol A145 of German Bayer Chemical and the water-based acrylic resin Maincote of American Dow Chemical. TM HG-54C is a mixture mixed in a mass ratio of 3:1, the pigment is TR92 from Huntsman in the United States, the dispersant is HLD-18 / AJ from Silcona in Germany, and the water-based defoamer is Surfynol MD-20 from Gas Chemical in the United States. The substrate wetting agent is C-600 from Silcona in Germany, the UV absorber is TINUVIN 1130 from BASF, the light stabilizer is TINUVIN 292 from BASF, the thickener is Tego 3010, and the polyisocyanate curing agent is N3390 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com