Preparation method of sphere-like alpha-phase nano aluminum oxide

A nano-alumina, spherical-like technology, applied in chemical instruments and methods, alumina/aluminum hydroxide, nanotechnology, etc. The effect of mass production, reduced size, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing spherical α-phase nano-alumina provided by the present invention comprises the following steps:

[0037] (a), ultrasonically treating the mixture of ground industrial alumina, water, ammonium citrate and ammonium fluoride to obtain alumina precursor slurry;

[0038] (b) performing solid-liquid separation on the alumina precursor slurry obtained in step (a), and drying the separated solid at 80-110°C to obtain a solid alumina precursor;

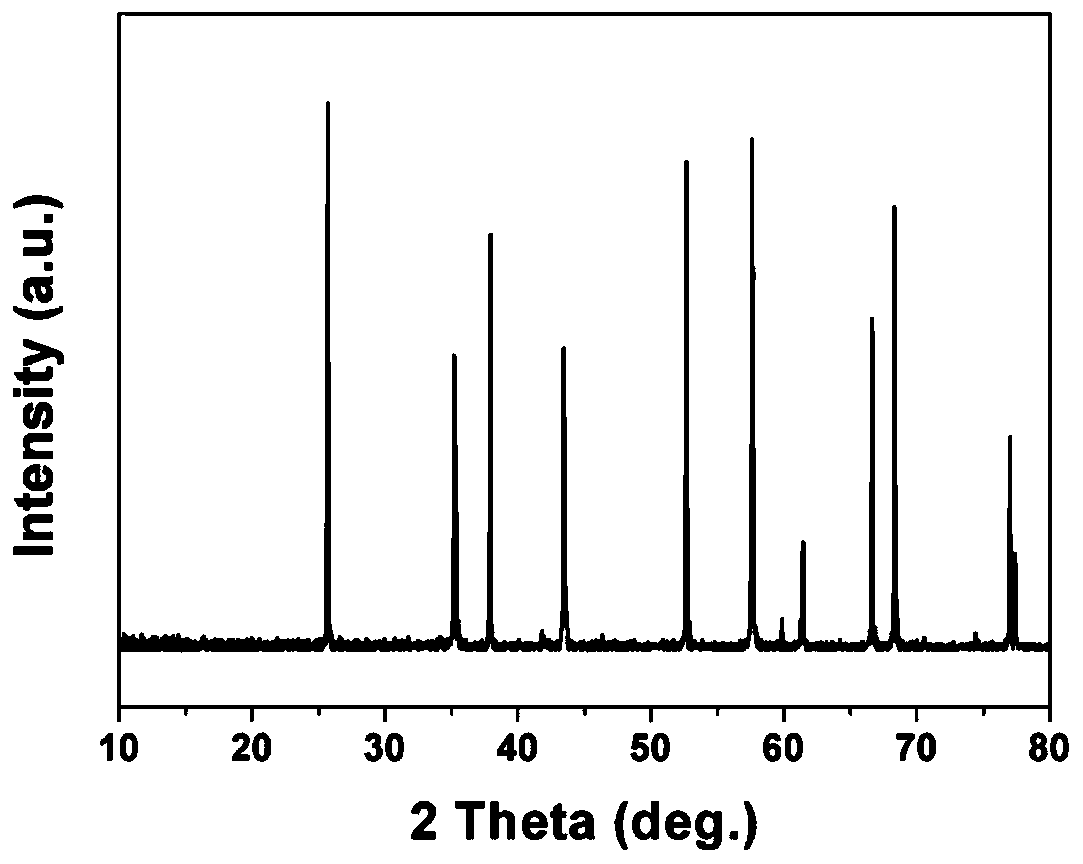

[0039] (c) Calcining the solid alumina precursor obtained in step (b) at 1200-1300° C. to obtain the spherical α-phase nano-alumina.

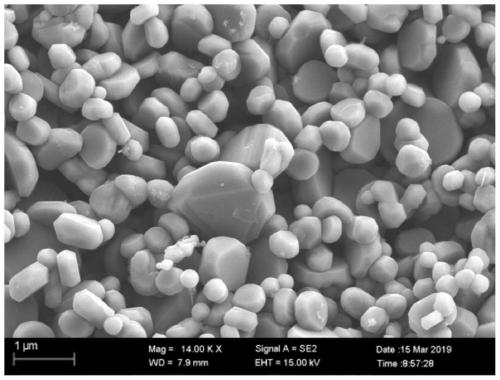

[0040] The preparation method provided by the present invention uses industrial alumina as a raw material, and prepares spherical α-phase nano-alumina powder by means of grinding, adding additives, ultrasonication, pre-calcination, calcination, etc., and the alumina powder Na 2 The O content is less than 0.02%, which solves the problem that the existing technology cannot simultan...

Embodiment 1

[0060] The preparation method of low-sodium spherical alpha-phase nano-alumina of the present invention comprises the following steps:

[0061] (1) Put industrial alumina raw materials into a planetary ball mill for ball milling, the medium of ball milling is zirconia balls, the diameter of zirconia balls is 1mm, and the grinding time is 3h;

[0062] (2) mixing the aluminum oxide prepared in step (1) with deionized water, the addition of deionized water is equivalent to 1 times the weight of industrial alumina, and it is made into a 50% aluminum oxide suspension;

[0063] (3) add composite additive to the alumina suspension that step (2) makes, the addition of ammonium citrate is 1% of alumina weight in the composite additive, and the addition of ammonium fluoride is 1% of alumina weight, Prepared as an alumina precursor;

[0064] (4) Reacting the alumina precursor prepared in step (3) under the action of ultrasound at a water bath temperature of 60° C. and a frequency of 80 ...

Embodiment 2

[0071] The preparation method of low-sodium spherical alpha-phase nano-alumina of the present invention comprises the following steps:

[0072] (1) put the industrial alumina raw material into a planetary ball mill for ball milling, the medium of the ball mill is a zirconia ball, the diameter of the zirconia ball is 2mm, and the grinding time is 5h;

[0073] (2) mixing the aluminum oxide prepared in step (1) with deionized water, the addition of deionized water is equivalent to 1 times the weight of industrial alumina, and it is made into a 50% aluminum oxide suspension;

[0074] (3) add composite additive to the alumina suspension that step (2) makes, the addition of ammonium citrate is 1% of alumina weight in the composite additive, and the addition of ammonium fluoride is 1% of alumina weight, Prepared as an alumina precursor;

[0075] (4) Reacting the alumina precursor prepared in step (3) under the action of ultrasound at a water bath temperature of 60° C. and a frequenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com