High-efficient stone breaking machine for drilling and production

A high-efficiency, stone-breaking technology, applied in grain processing, etc., can solve problems such as inability to function, consume a large amount of labor, and inconvenient movement, etc., to achieve fast and convenient crushing and cleaning, reduce work intensity, and use well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

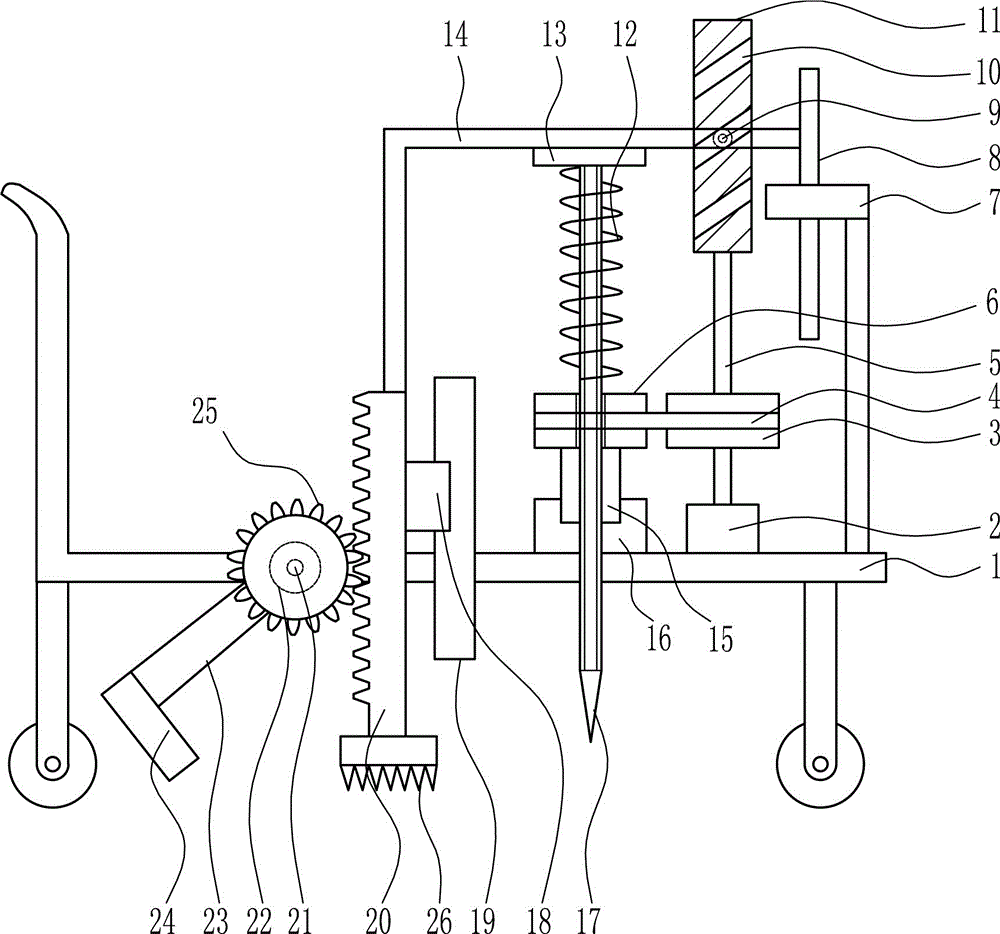

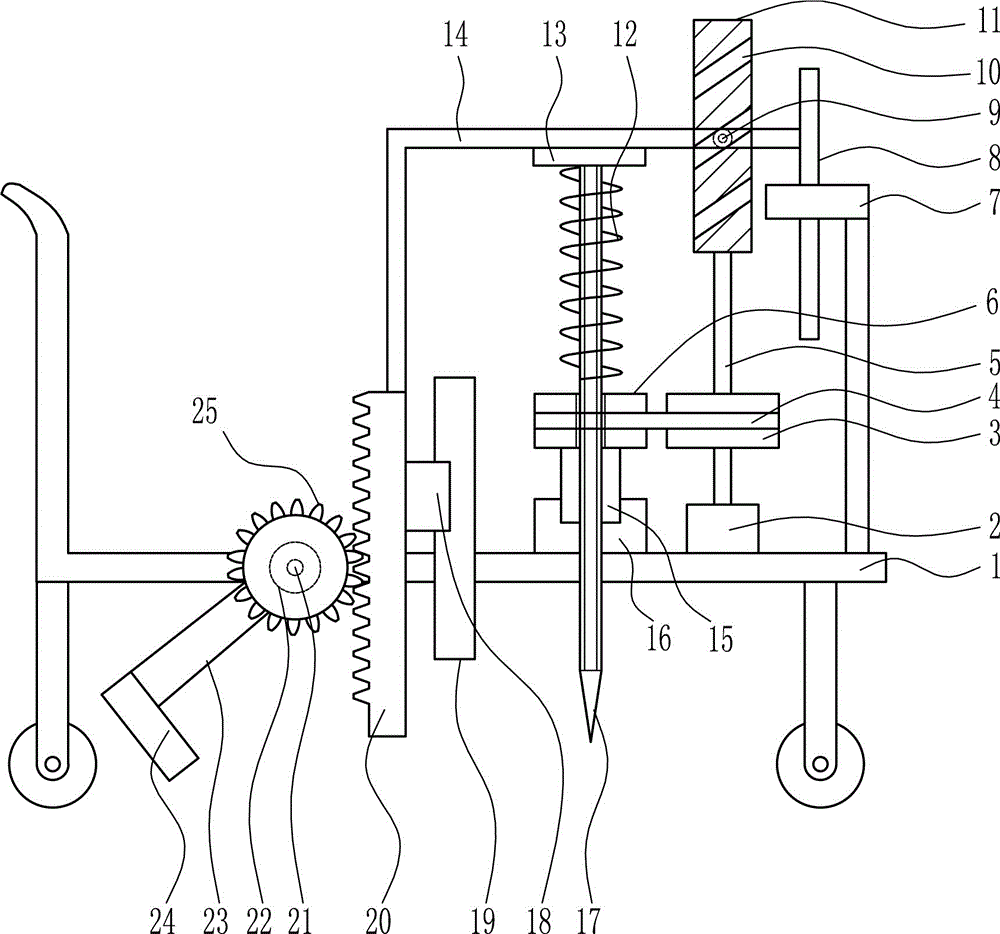

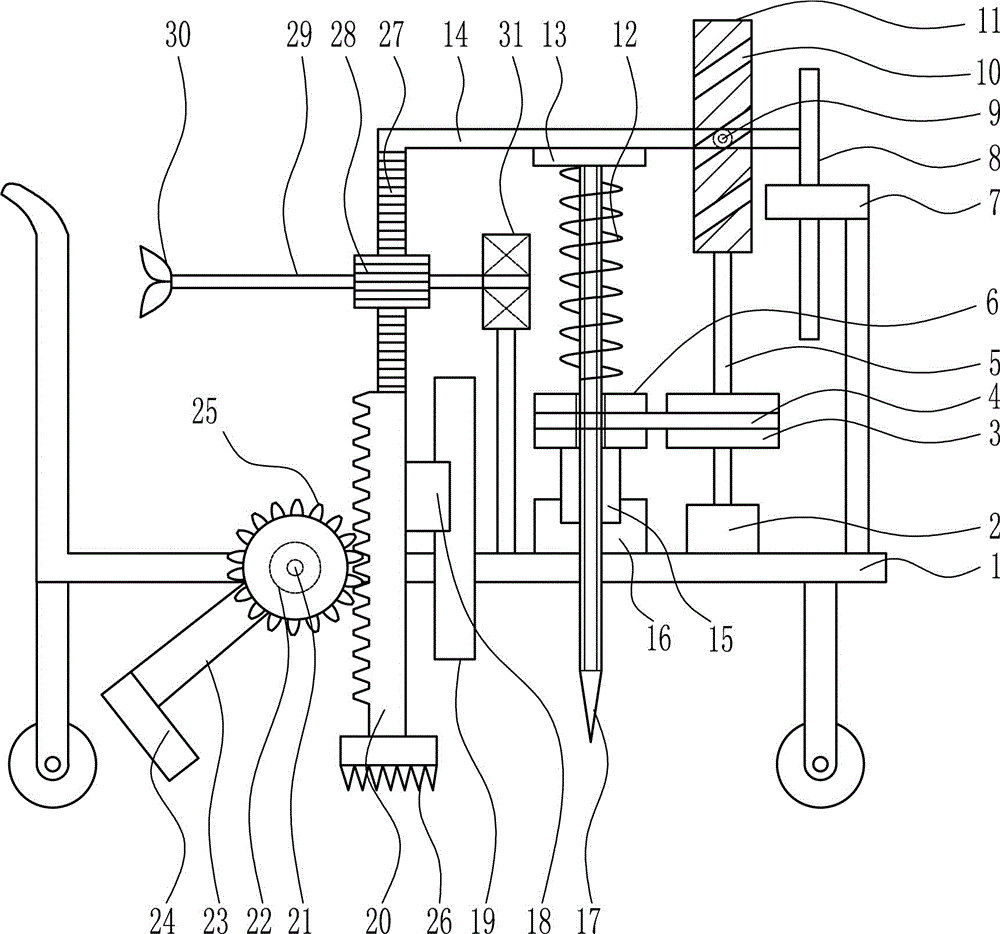

[0025] A kind of drilling adopts high-efficiency rock-breaking equipment, such as Figure 1-3 As shown, it includes a trolley 1, a motor 2, a second pulley 3, a connecting belt 4, a second rotating shaft 5, a first pulley 6, a guide rail 7, a lifting rod 8, a roller 9, a drum 11, a spring 12, and a connecting plate 13. Connecting rod 14, connecting disc 15, second bearing seat 16, drill bit 17, slider 18, slide rail 19, first rack 20, first rotating shaft 21, first bearing seat 22, swing rod 23, hammer head 24 and the first gear 25; the top of the trolley 1 is provided with the second bearing seat 16, the motor 2 and the guide rail 7 successively from left to right, the second bearing seat 16 is provided with a connection plate 15, and the top of the connection plate 15 is provided with a first Pulley 6, the first pulley 6 is provided with a drill bit 17, the first pulley 6 is provided with a keyway, the drill bit 17 is provided with splines, the splines cooperate with the key...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com