A high-efficiency paint spraying device for zinc alloy tubes

A technology of zinc alloy and tube height, which is applied in the field of high-efficiency painting equipment for zinc alloy tubes, can solve the problems of low painting efficiency and achieve high painting efficiency

Active Publication Date: 2022-05-31

WUXI TONGXIN PLASTIC PROD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In order to overcome the shortcomings of low painting efficiency of the existing zinc alloy pipe painting device, the technical problem to be solved by the present invention is to provide a high-efficiency painting device for zinc alloy pipe with high painting efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

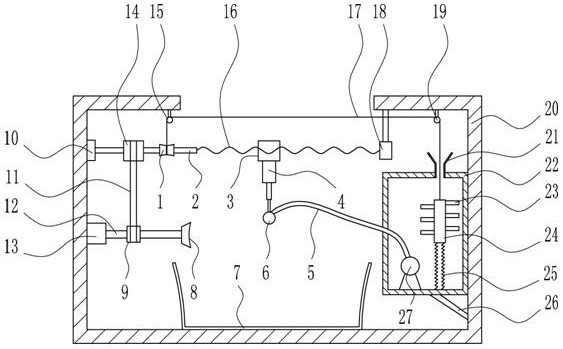

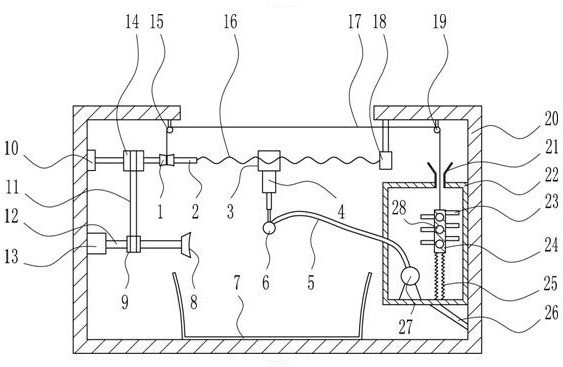

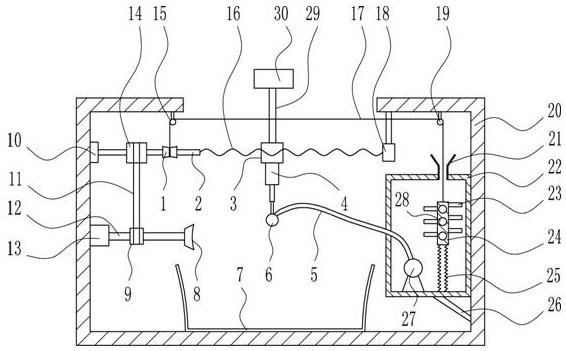

The invention relates to a painting device, in particular to a high-efficiency painting device for zinc alloy tubes. The technical problem to be solved by the invention is to provide a high-efficiency painting device for zinc alloy tubes with high painting efficiency. In order to solve the above technical problems, the present invention provides such a high-efficiency paint spraying device for zinc alloy tubes, which includes a winding wheel, a second rotating shaft, a nut, an electric push rod, a hose, a spray head, a collection tank, an electric suction cup, and a small pulley , left bearing seat, flat belt, first rotating shaft, etc.; there is a collecting tank in the middle of the inner bottom of the bracket, the left bearing seat and servo motor are arranged on the inner left wall of the bracket, and the left bearing seat is set above the servo motor, and the right end of the servo motor is connected to There is a first rotating shaft, and a small belt pulley is arranged on the first rotating shaft. The invention achieves the effect of high painting efficiency, adopts a rotating and moving painting method during the painting process, carries out all-round painting treatment on the zinc alloy pipe, and collects redundant paint materials.

Description

A high-efficiency paint spraying device for zinc alloy pipes technical field The present invention relates to a kind of paint spraying device, relate in particular to a kind of high-efficiency paint spraying device of zinc alloy pipe. Background technique [0002] Zinc alloy is an alloy composed of other elements based on zinc. Commonly added alloying elements are aluminum, copper, magnesium, cadmium, Low temperature zinc alloys such as lead and titanium. Zinc alloy has low melting point, good fluidity, easy fusion welding, brazing and plastic processing, corrosion resistance in the atmosphere, Residual waste is easy to recycle and remelt, but it has low creep strength and is prone to dimensional changes caused by natural aging. Fusion method, die casting Or pressure processed into wood. According to the manufacturing process, it can be divided into cast zinc alloy and deformed zinc alloy. The main added elements of zinc alloys are Aluminum, Copper and Magnesium e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B05B13/02B05B9/04B05B13/04B05B15/25B05B14/00B05B15/00

CPCB05B9/0403B05B13/0207B05B13/041B05B14/00B05B15/00B05B15/25Y02P70/10

Inventor 钱嘉良

Owner WUXI TONGXIN PLASTIC PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com