Punching synchronous burr removing equipment

A deburring and equipment technology, which is applied in the field of edge and burr removal devices and stamping synchronous deburring equipment, can solve the problems of burrs reappearing, and achieve the effects of increasing mechanical properties, improving wear resistance, and improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

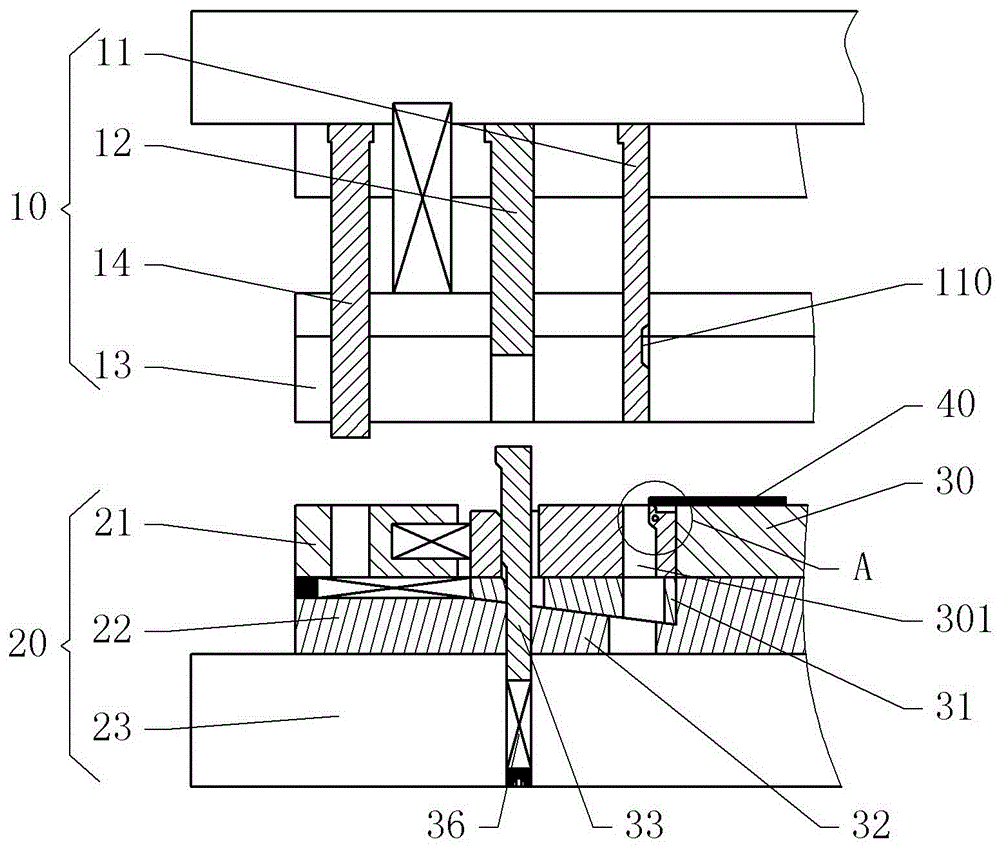

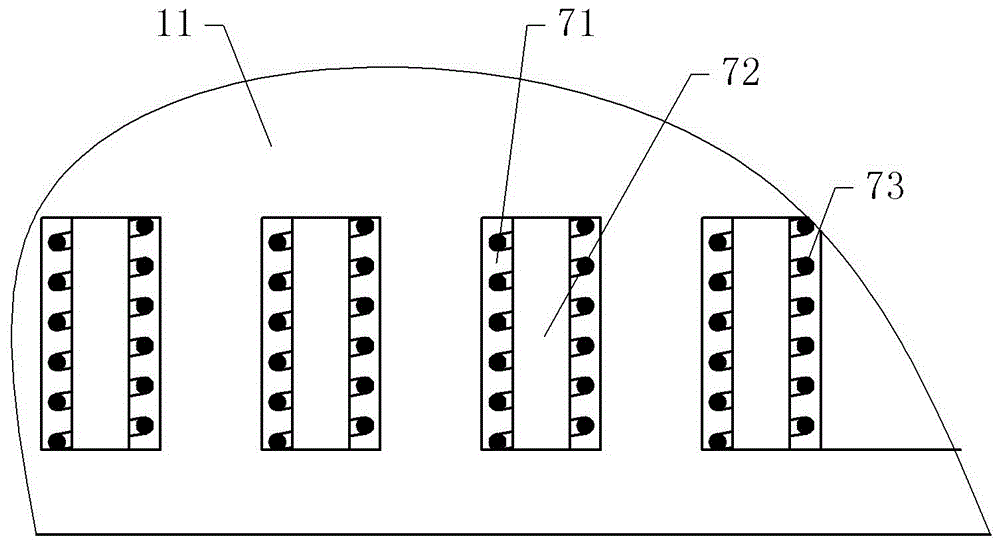

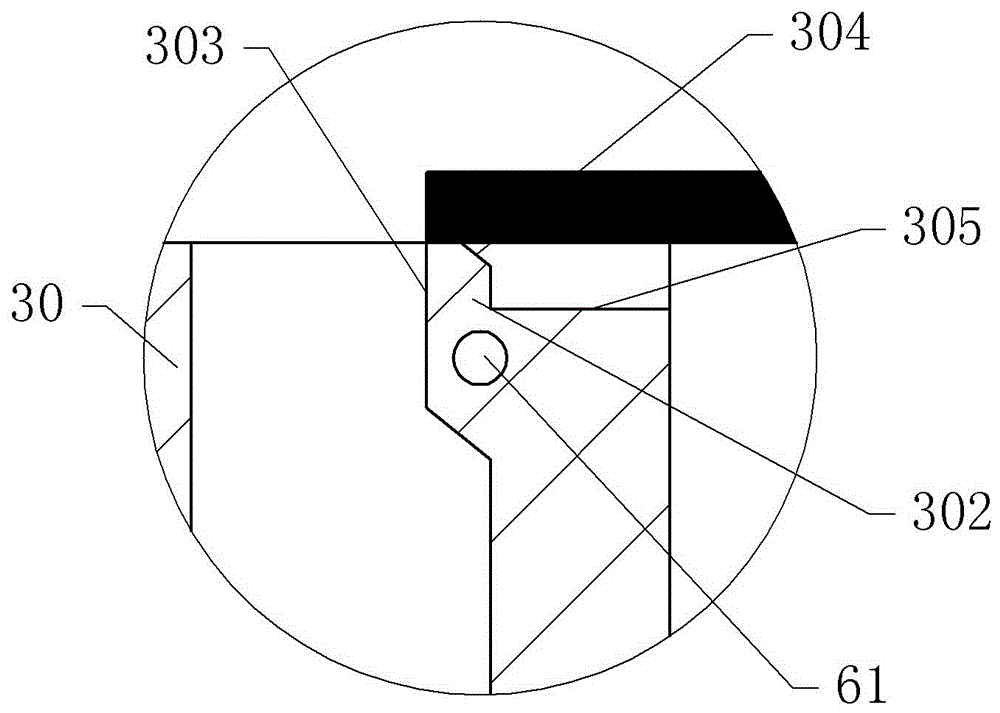

[0024] The reference signs in the drawings of the description include: upper die 10, notch punch 11, avoidance groove 110, wedge punch 12, stripper plate 13, small guide post 14, lower die 20, concave template 21, Lower backing plate 22, lower die base 23, die slider 30, punching hole 301, burr step 302, punching notch 303, chamfer 304, accommodation platform 305, upper and lower floating slider 31, slider pad 32 , oblique wedge 33, channel 34, return elastic member 36, workpiece 40, edge connecting material 41, cooling device 60, cooling channel 61, medium storage pipe 62, medium delivery pipe 63, pump 64, mounting hole 71, iron core 72 , Helical coil 73 .

[0025] Such as figure 1 , image 3As shown, the stamping synchronous deburring equipment of the present embodiment includes an upper die 10 and a lower die 20, two punches are arranged in the upper die 10, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com