Forging and stamping device of reducing tank

A reduction tank and forging technology, which can be applied to other household appliances, household appliances, applications, etc., can solve problems that affect the output and quality of metal magnesium crystallization bodies, raw material loss, fracture, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

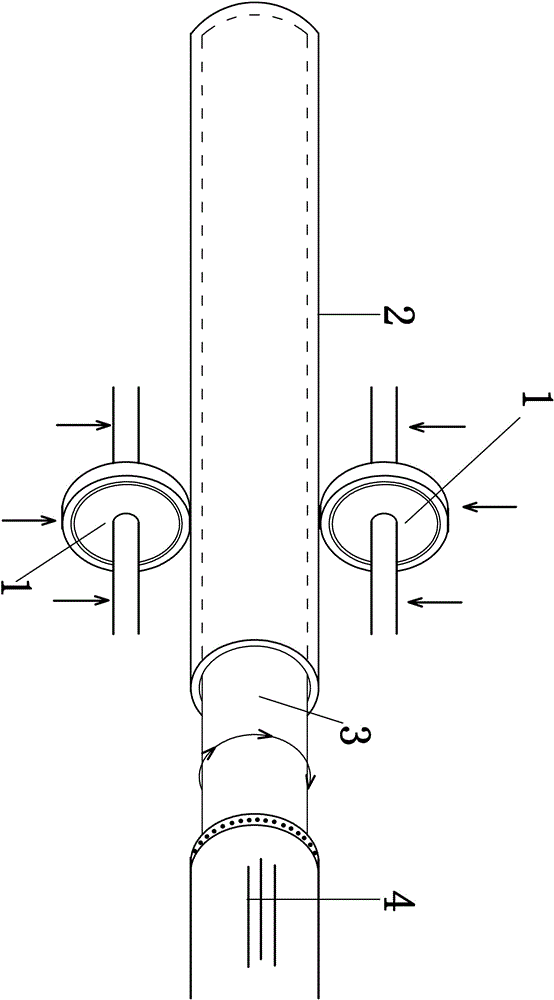

[0005] In the figure, a forging device for a reduction tank is used. After the cast reduction tank body (2) is heated, it is placed on the continuously rotating circular inner bracket (3). The circular inner bracket (3) and the rotating power (4) is linked, (4) is the rotating power device of the circular inner bracket (3); driven by the rotation of the circular inner bracket (3), the reduction tank ( 2) It also rotates together. At this time, the upper forging wheel (1) and the lower forging wheel (1) apply pressure to the surface of the reduction tank body (2) at the same time, and the forging pressure is dense, so that the pressure reduction tank body (2) is continuously and repeatedly discharged. ), so that the tank body of the reduction tank (2) is pressurized and densified, thereby increasing the strength and density of the reduction tank body, thus improving the service life of the reduction tank and the quality of the extraction and collection of metal magnesium crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com