Guide wheel base numerical control turning technology method

A processing technology and a technology of guide wheel seat, applied in the field of mechanical parts processing, can solve the problems of cumbersome processing technology of guide wheel seat, high use cost and production cost, poor versatility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

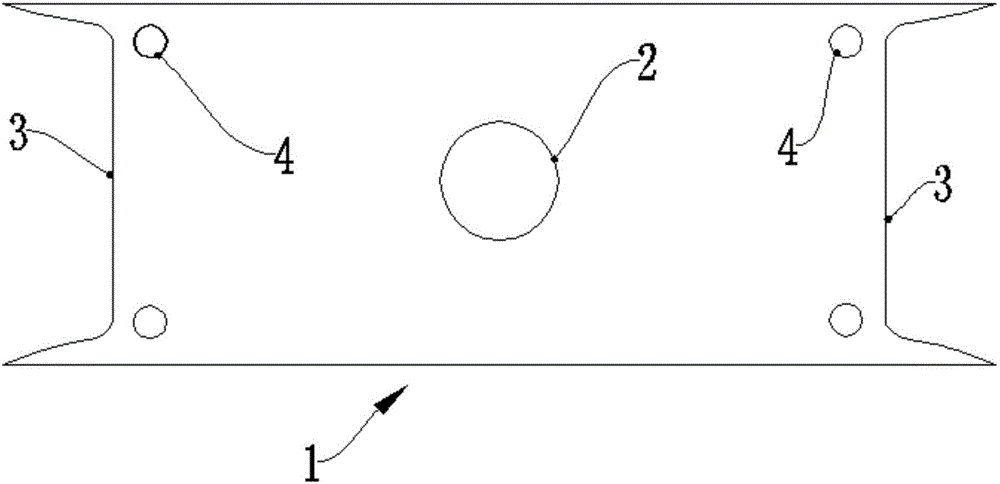

[0027] The numerical control turning process method of the guide wheel base of the present embodiment, such as figure 1 As shown, the middle part of the guide wheel seat 1 is provided with a positioning through hole 2, the two ends of the guide wheel seat 1 are provided with U-shaped grooves 3, and the periphery of the guide wheel seat 1 is provided with installation through holes 4, and the guide wheel seat 1 is processed. Include the following steps:

[0028] Step A, blanking, process a blank according to the specification blanking of the guide wheel seat 1, the length of the selected blank is 225mm, the width is 85mm, and the height is 30mm, and the material of the blank is No. 45 steel. The jaw chuck clamps the blank;

[0029] Step B, rough turning the surface of the blank on the CNC lathe, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com