Practical bi-directional drill machine tool

A drilling mechanism and two-way technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problems of complex drilling process and low drilling efficiency, and achieve easy promotion, The effect of improving drilling efficiency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

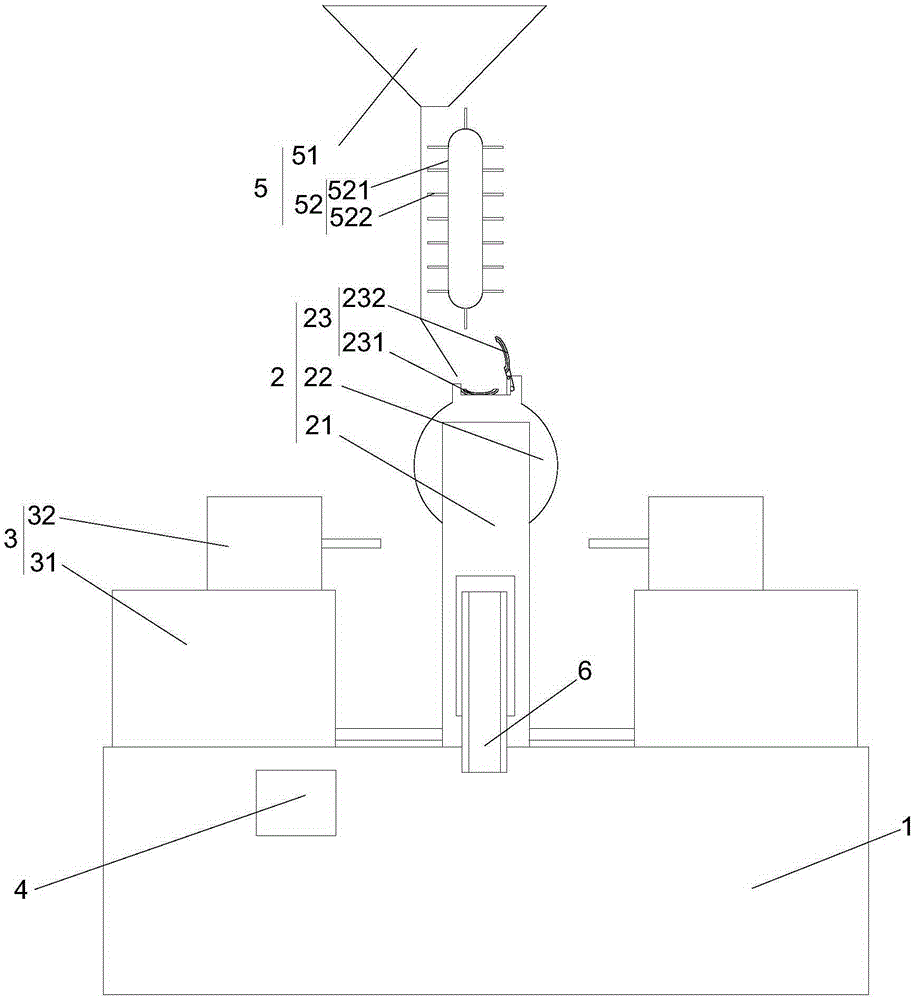

[0015] refer to figure 1 As shown, a kind of practical two-way drilling machine tool that the present invention proposes, comprises frame 1, clamping mechanism 2 and two drilling mechanisms 3;

[0016] Two drilling mechanisms 3 are installed on both sides of the frame 1 respectively, and the clamping mechanism 2 is fixedly installed between the two drilling mechanisms 3; the drilling mechanism 3 includes a mobile device 31 and a drilling device 32, and the mobile device 31 is movable Installed on the frame 1, the drilling device 32 is installed on the moving device 31; the clamping mechanism 2 includes a supporting device 21, a clamping device 22 and two fixed clips 23, and the clamping device 22 is rotatably installed on the supporting device 21 Above, the fixing clips 23 are installed on the clamping device 22 and evenly distributed.

[0017] In this embodiment, when the clamping device 22 is not rotated against the supporting device 21, the two fixing clips 23 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com