Patents

Literature

65results about How to "Improve management accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

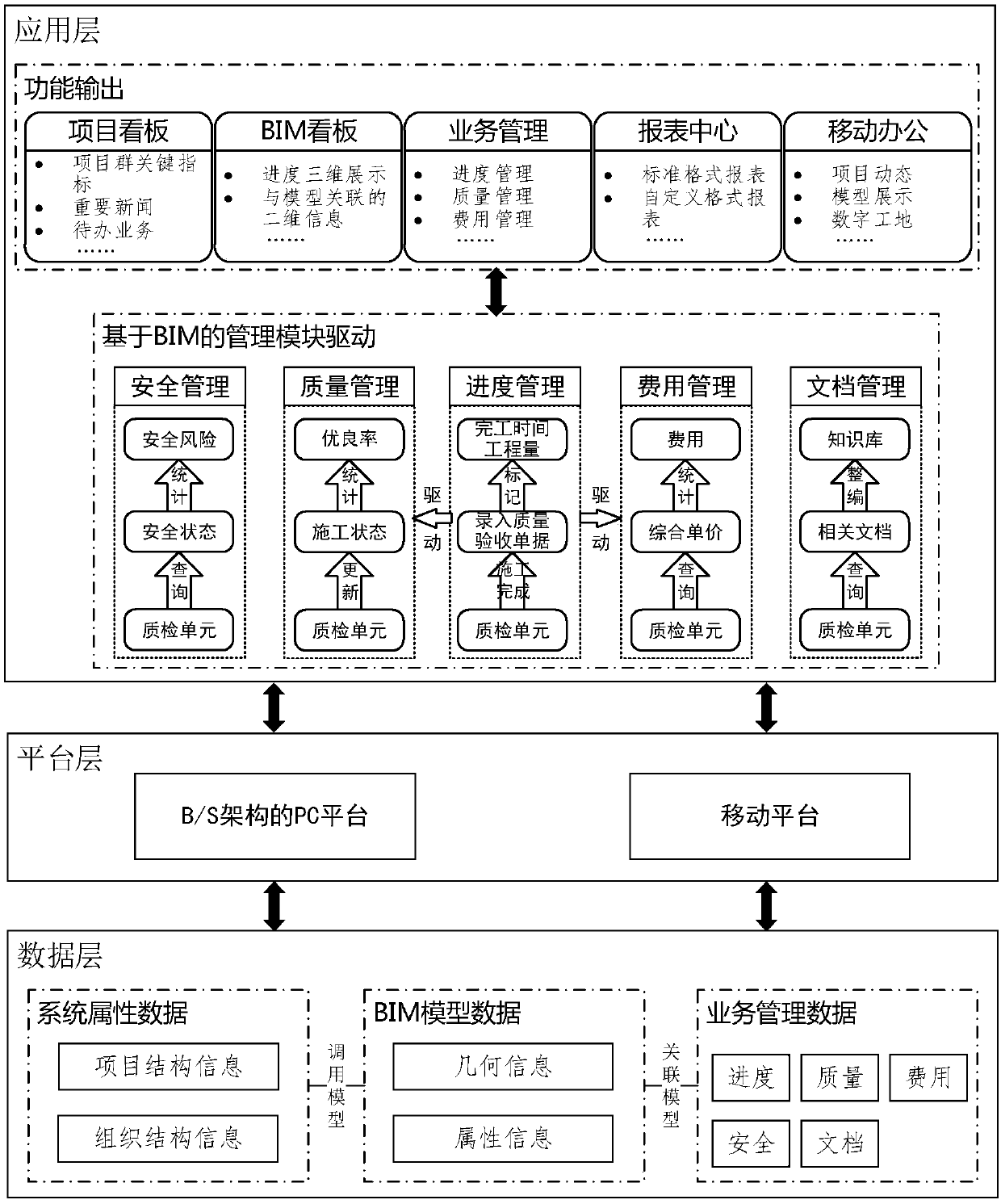

Digital management system and method for project construction processes

ActiveCN107622355AImprove acquisitionImprove circulation speedOffice automationResourcesBusiness managementProtocol Application

The invention discloses a digital management system for project construction processes. The system comprises a data layer, a platform layer and application layers, wherein the data layer comprises a BIM construction module which is created via a division principle of a construction quality management unit; the data layer comprises system attribute data, BIM model data and business management data;the platform layer consists of a B / S architecture-adopted PC platform and a mobile platform; the PC platform application layer consists of a project board module, a BIM board module, a business management module and a statement center module; a business management module comprises a progress management module, a quality management module, a safety management module, an expense management module and a document management module; and a mobile platform application layer is a mobile office layer which consists of a project dynamic module, a model display module and a digital construction site module. The system has the advantage of improving the management precision and efficiency of project construction processes.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

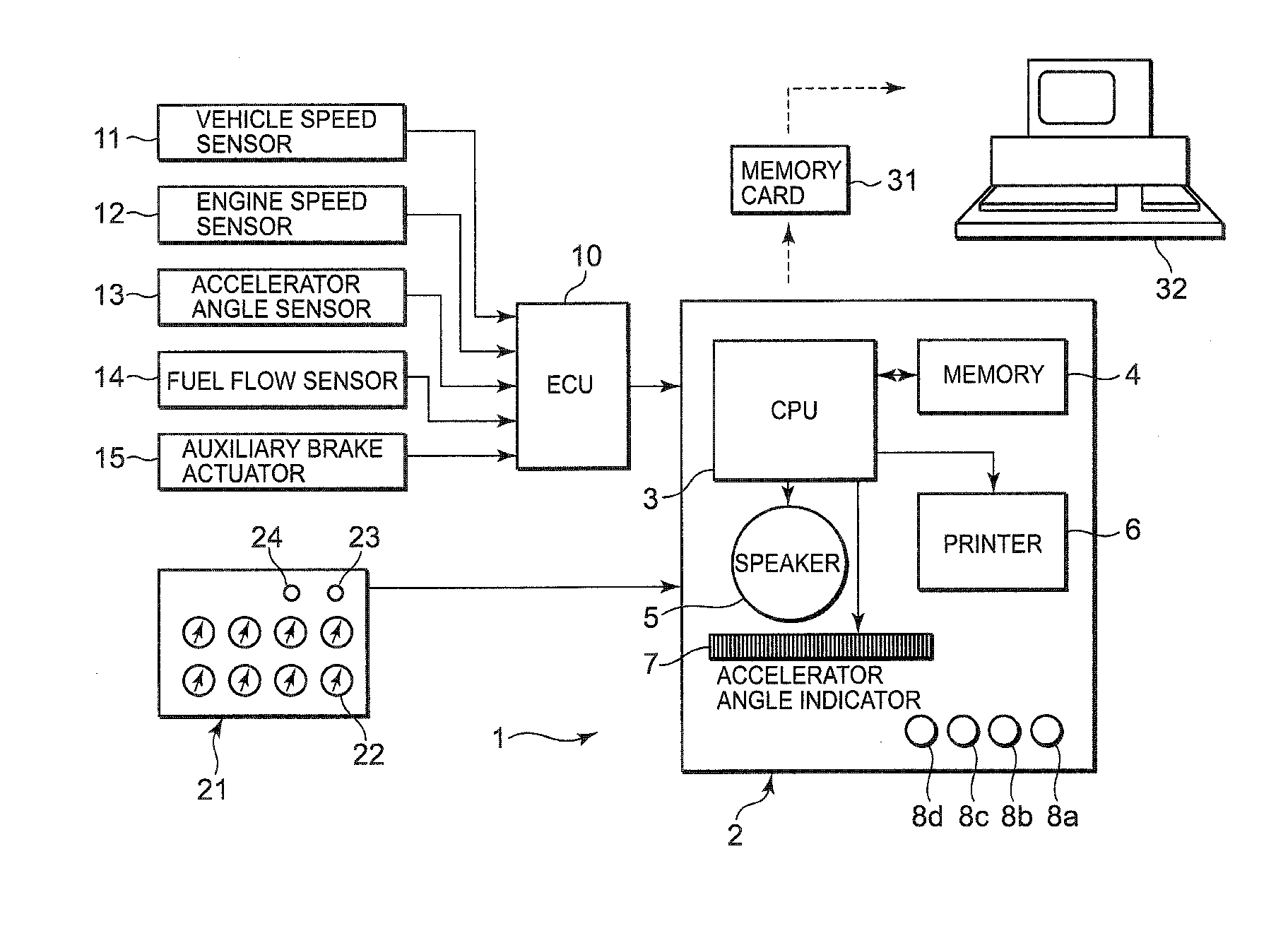

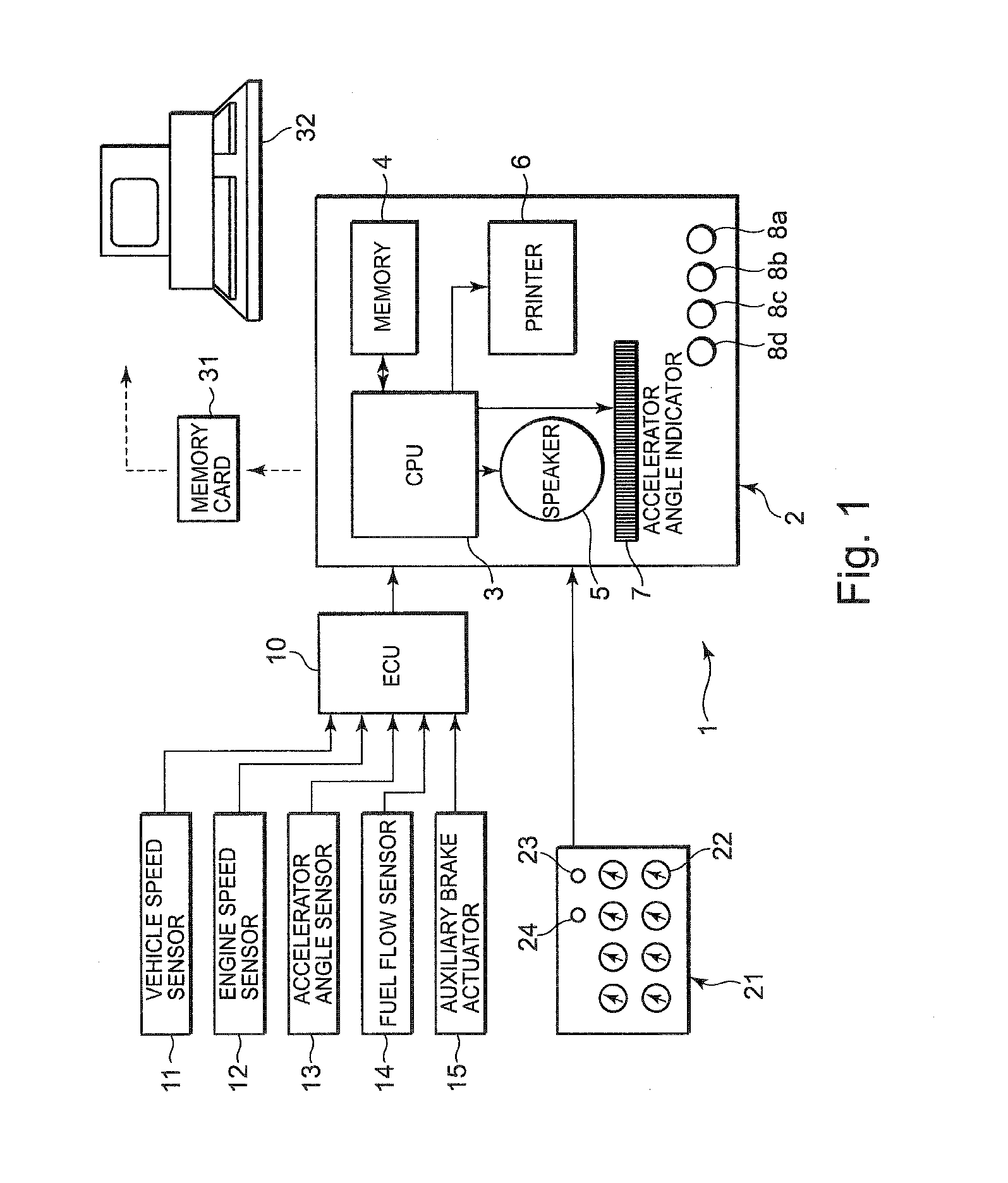

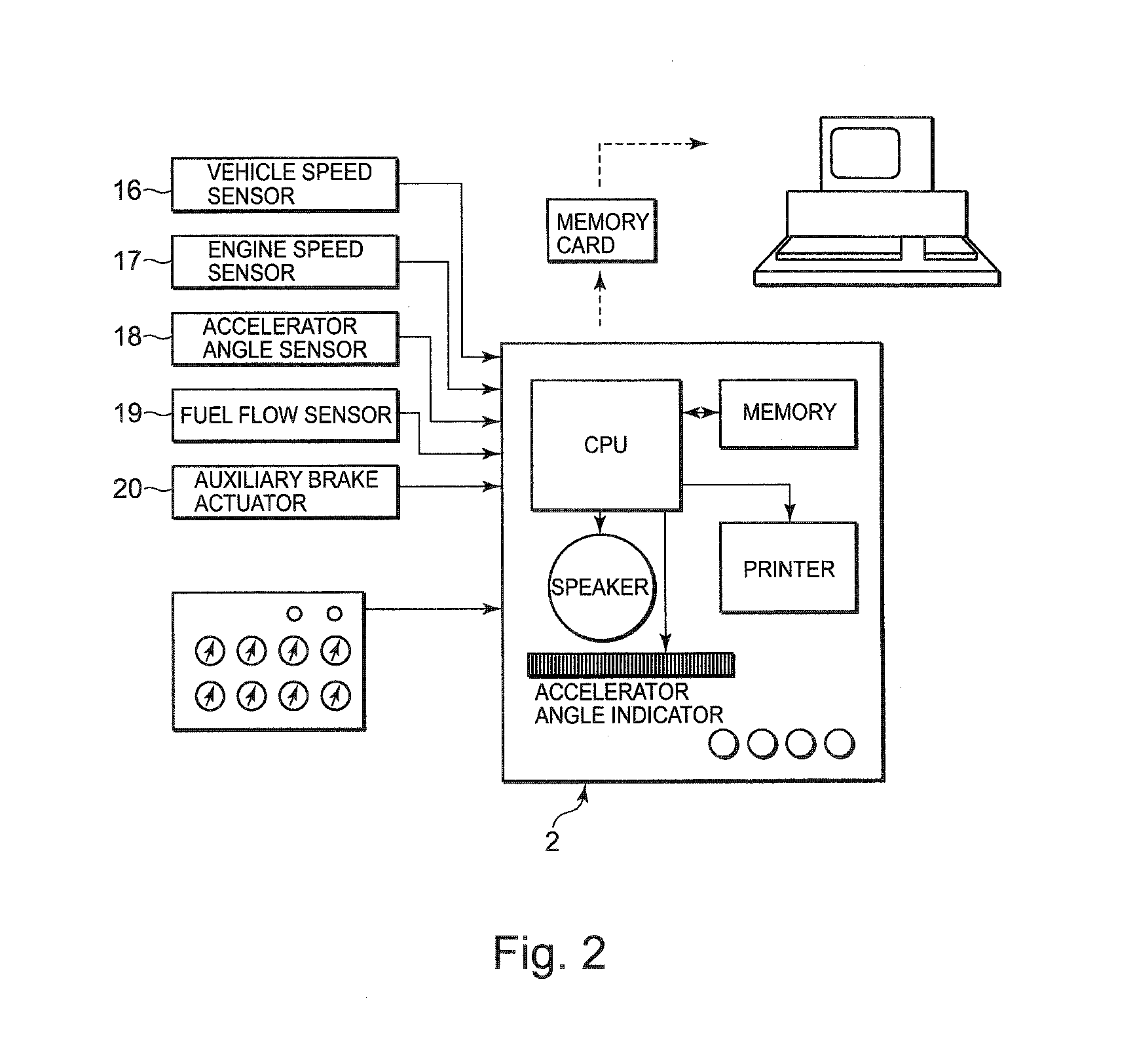

Fuel-saving management system

InactiveUS20070213920A1Reduce mental burdenEasy to set upVehicle testingAnalogue computers for vehiclesSystem configurationData profiling

This invention relates to a fuel-saving management system that allows fuel-saving management and associated driver assistance to be conducted very smoothly. The constituent elements of this system include the following mounted on a vehicle: information detectors (11 to 15) for detecting various information on the driving state of the vehicle, an information processor (3) for, in addition to processing the information detected by the information detectors, generating a warning when processed information satisfies required warning conditions, and an information storage device (4) for storing the processed information. In this system, when either a time during which the processed information is maintained to satisfy the required warning conditions, or an elapsed time of the processed information exceeds a previously set time, the information processor stores the occurrence of this overtime event into the information storage device. A setter (21) for allowing modification of the required warning conditions, and a printer (6) that can output the information relating to the processed information are also mounted. In a different system configuration, an information processor (3) for calculating the cumulative traveling distance through which without using an auxiliary brake, and an information storage device (4) for storing the cumulative traveling distance are mounted in a vehicle-mounted analyzer (1) and / or a vehicle owner / user company's data analyzer (32).

Owner:HINO MOTORS LTD

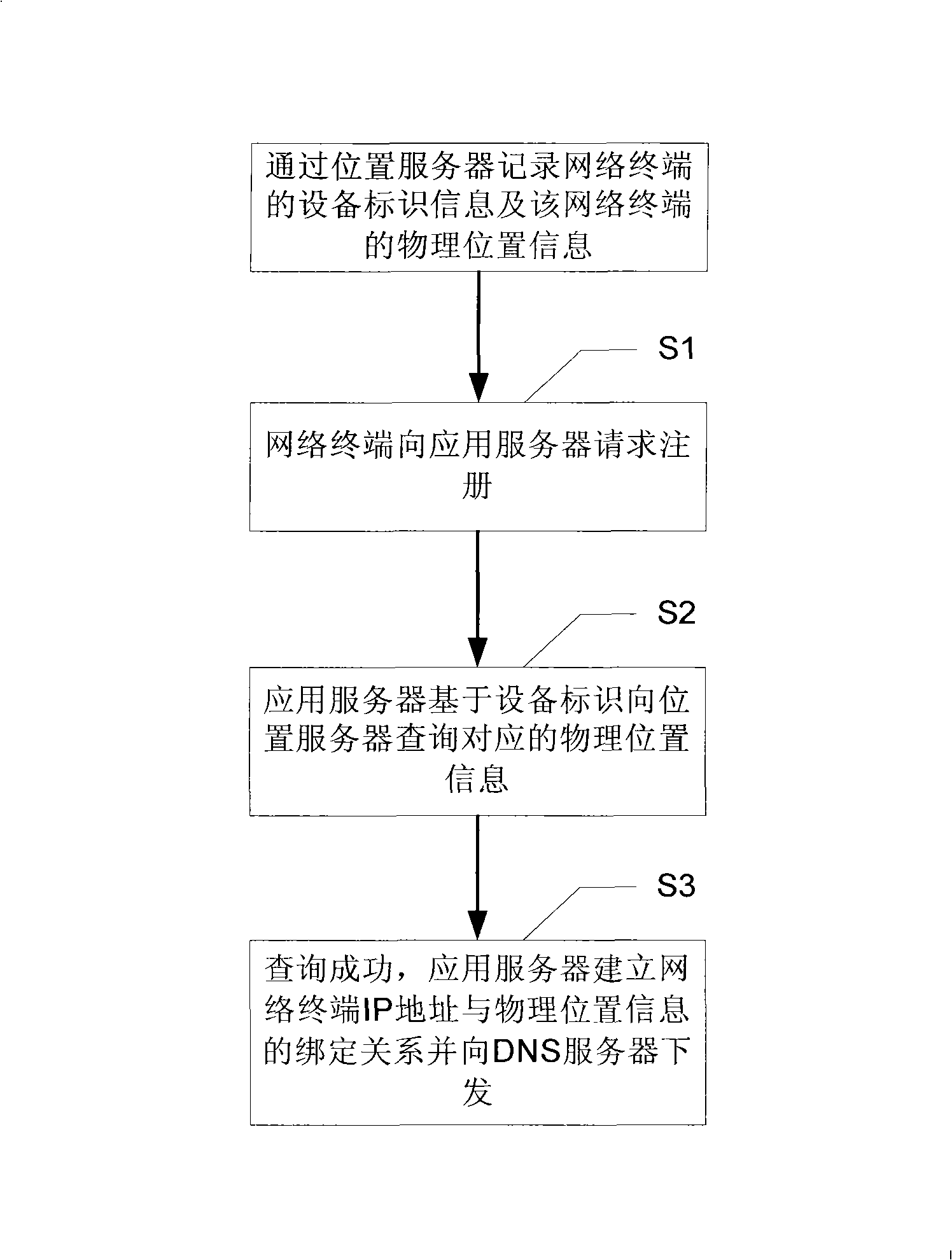

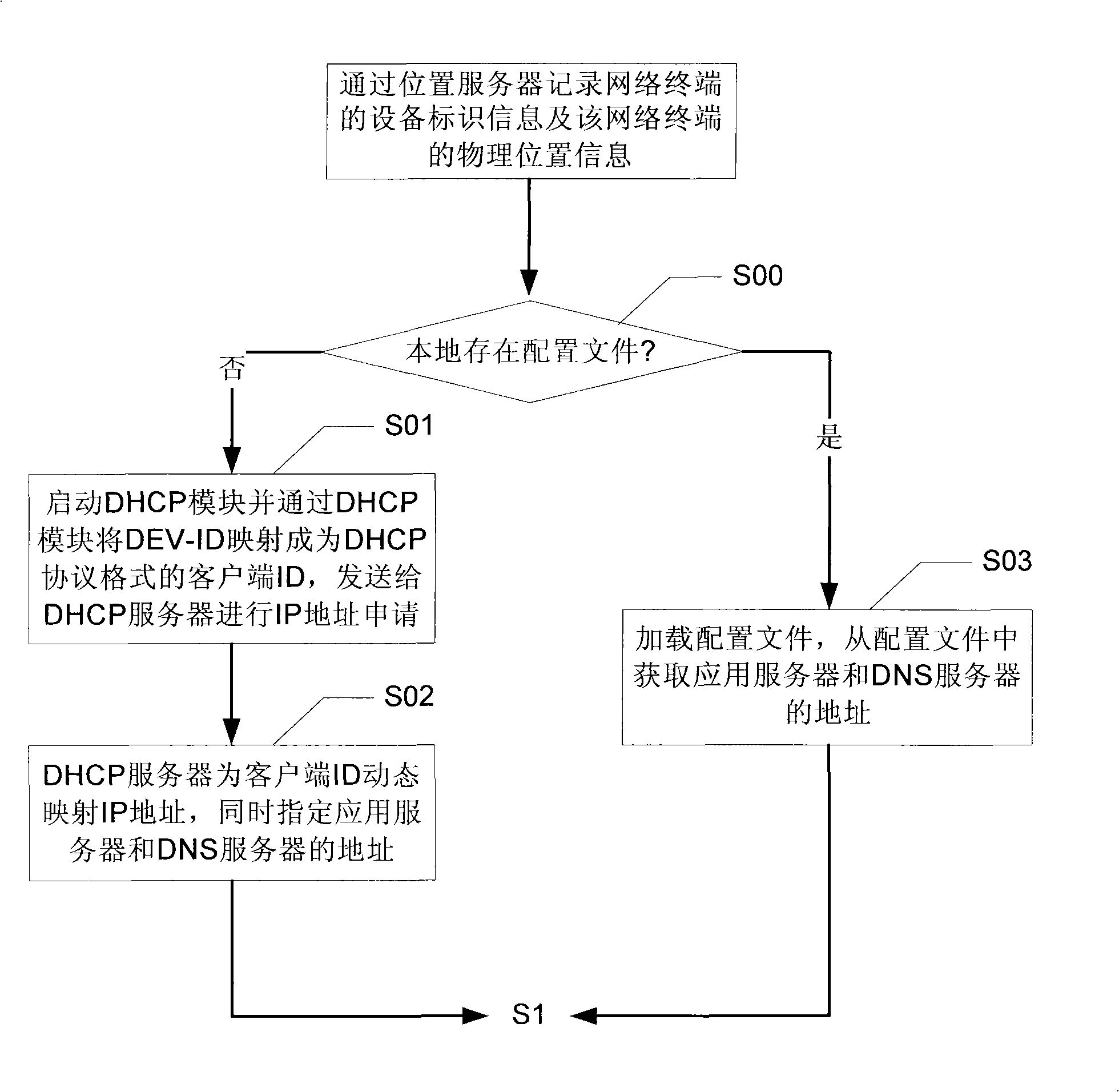

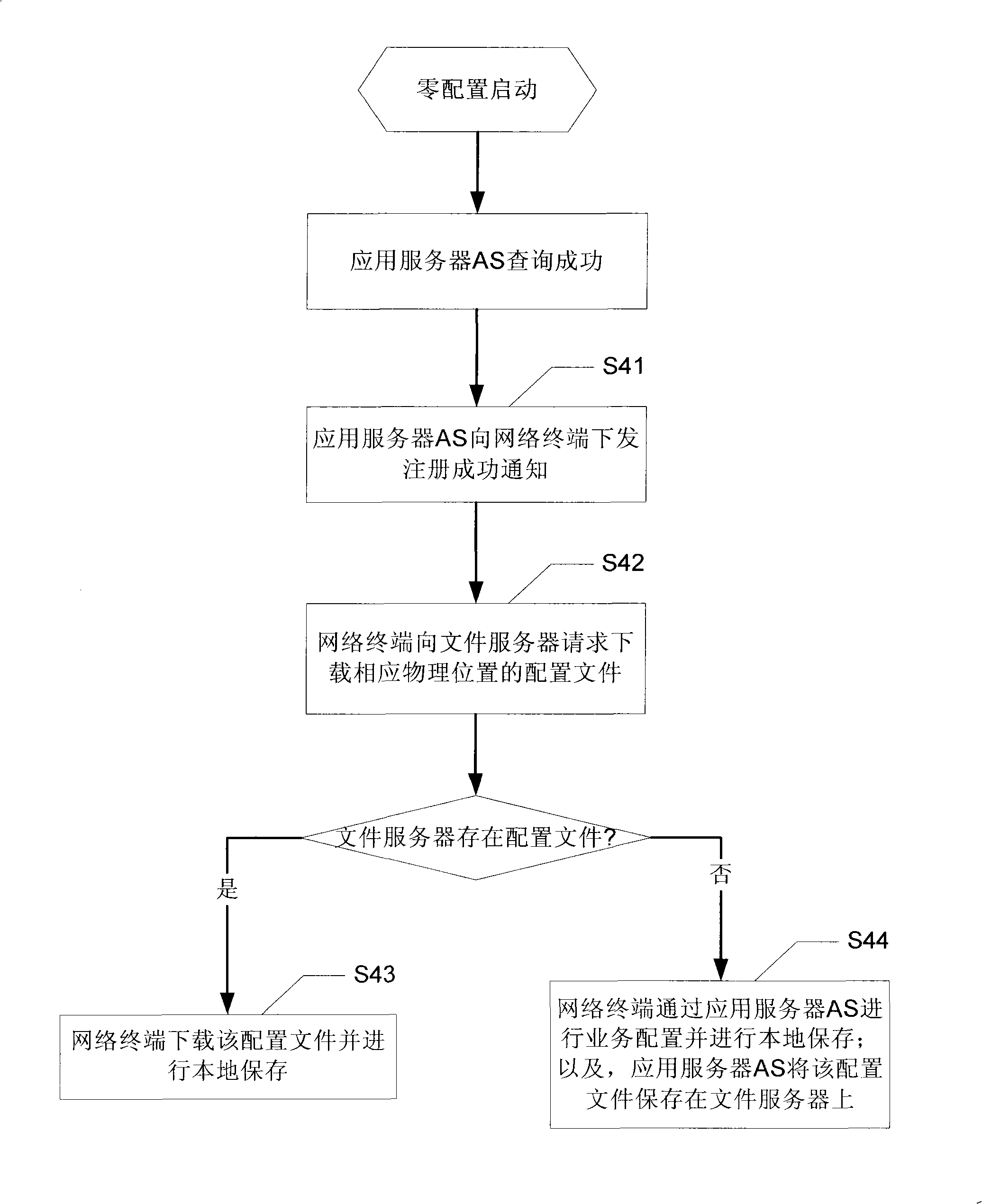

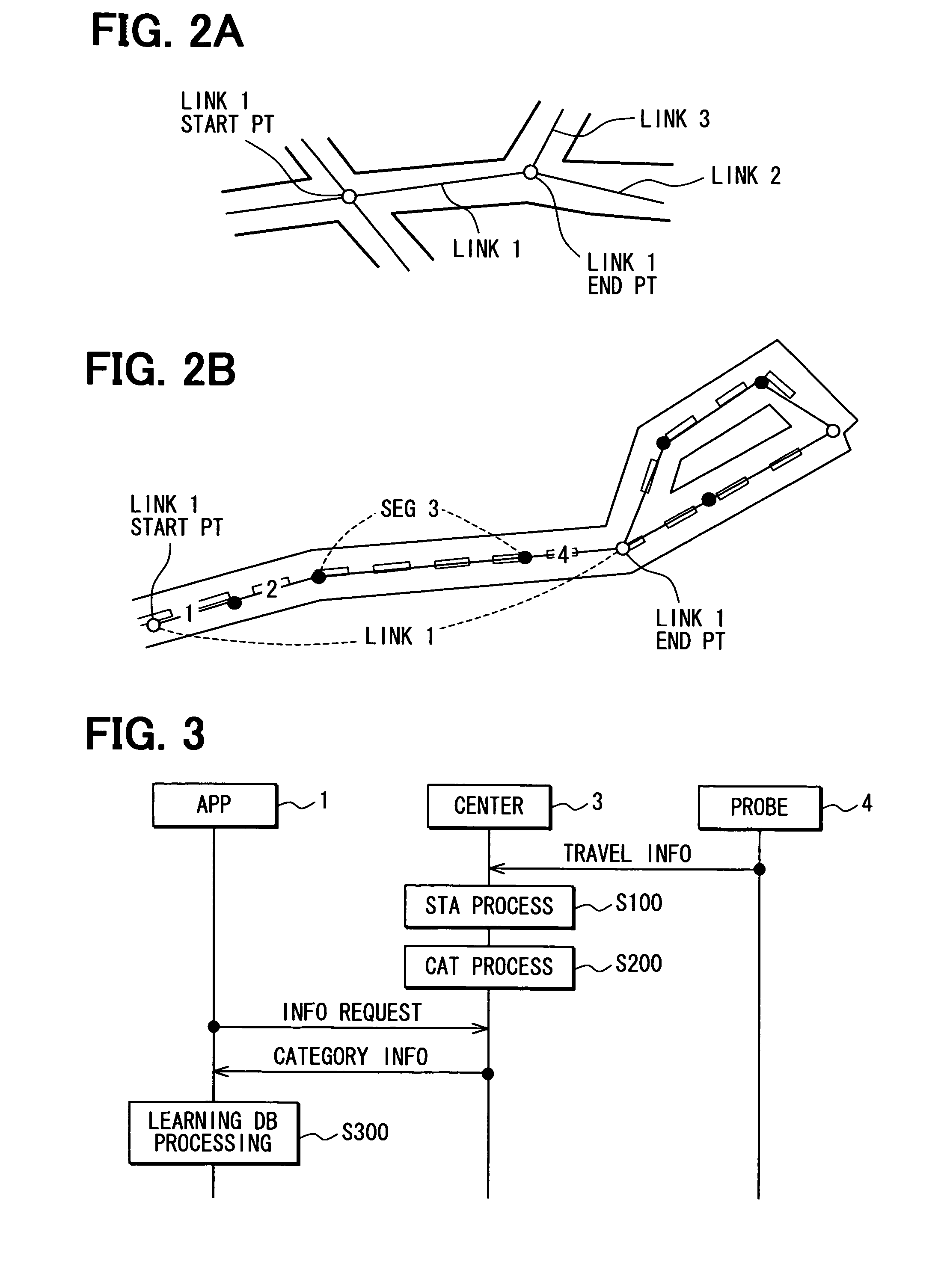

Network terminal control method and network terminal control system

InactiveCN101345659AEasy to deployEasy maintenanceData switching networksNetwork terminationControl system

The invention discloses a network terminal control method and a network terminal control system, comprising: recording device identification information of the network terminal and physical position information of the network terminal through a position server, and executing the steps after starting a network terminal: the network terminal request to register to an applying server, wherein the registering information is carried with ID address of the network terminal and the device identification information; the applying server inquires the physical position information corresponding to the network terminal to the position server based on the physical position information; if true, the applying server builds binding relation between the IP address of the network terminal and the physical position information and sends down to a DNS server, to perform visit on the network terminal based on the physical position information. According to the invention, it is in favor of disposition of larger network, thereby effectively reducing maintaining difficulty of the network terminal.

Owner:NEW H3C TECH CO LTD

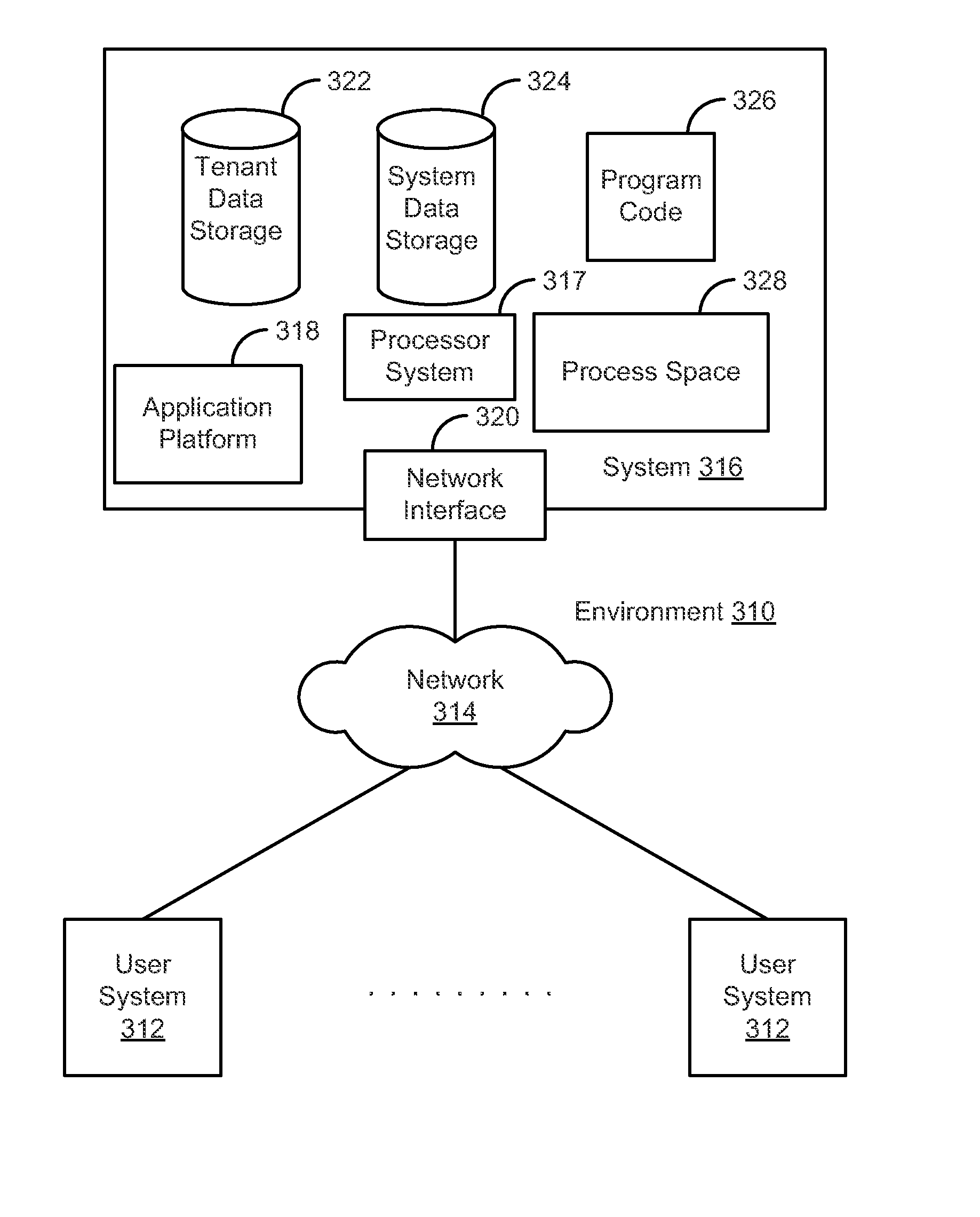

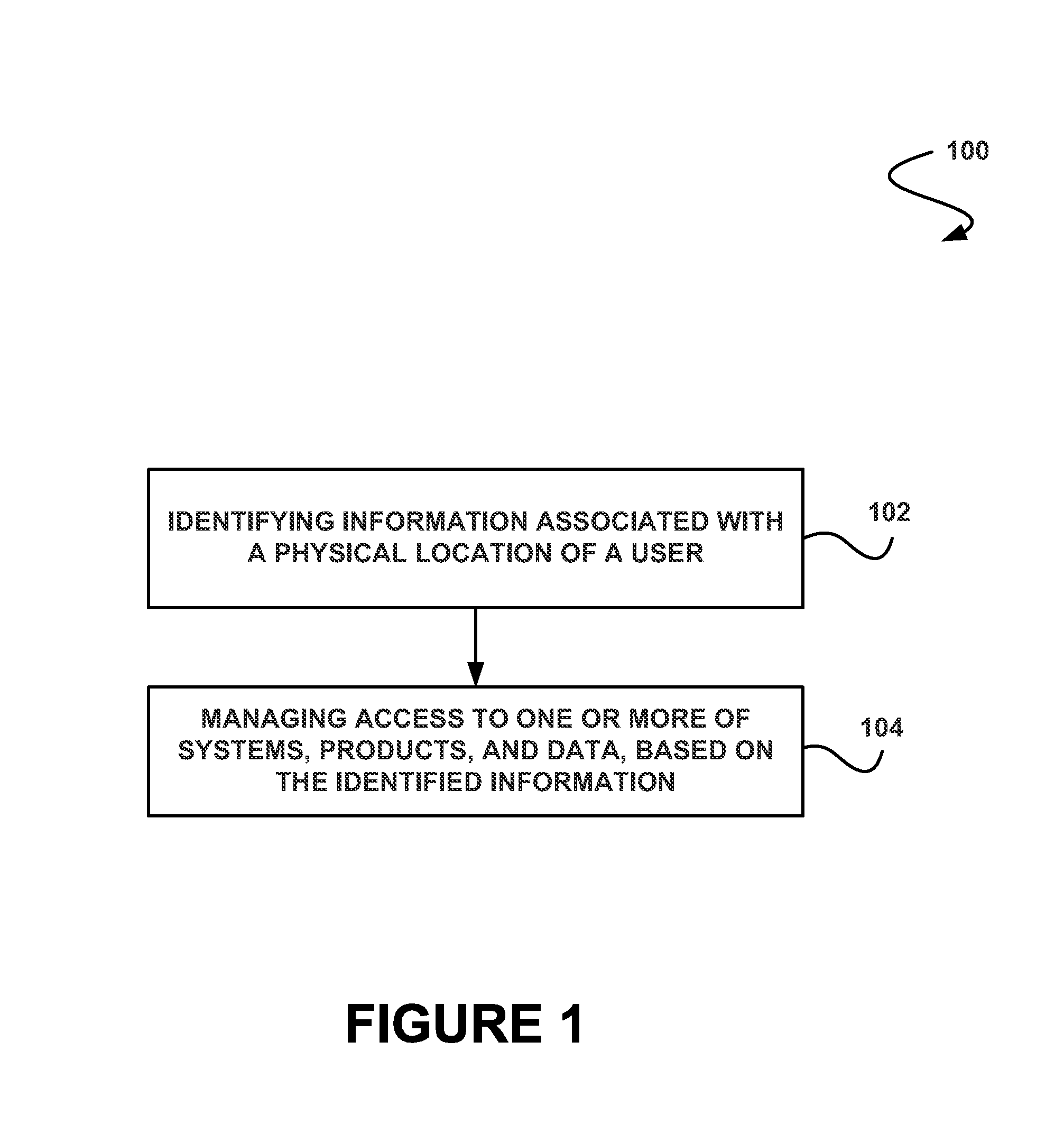

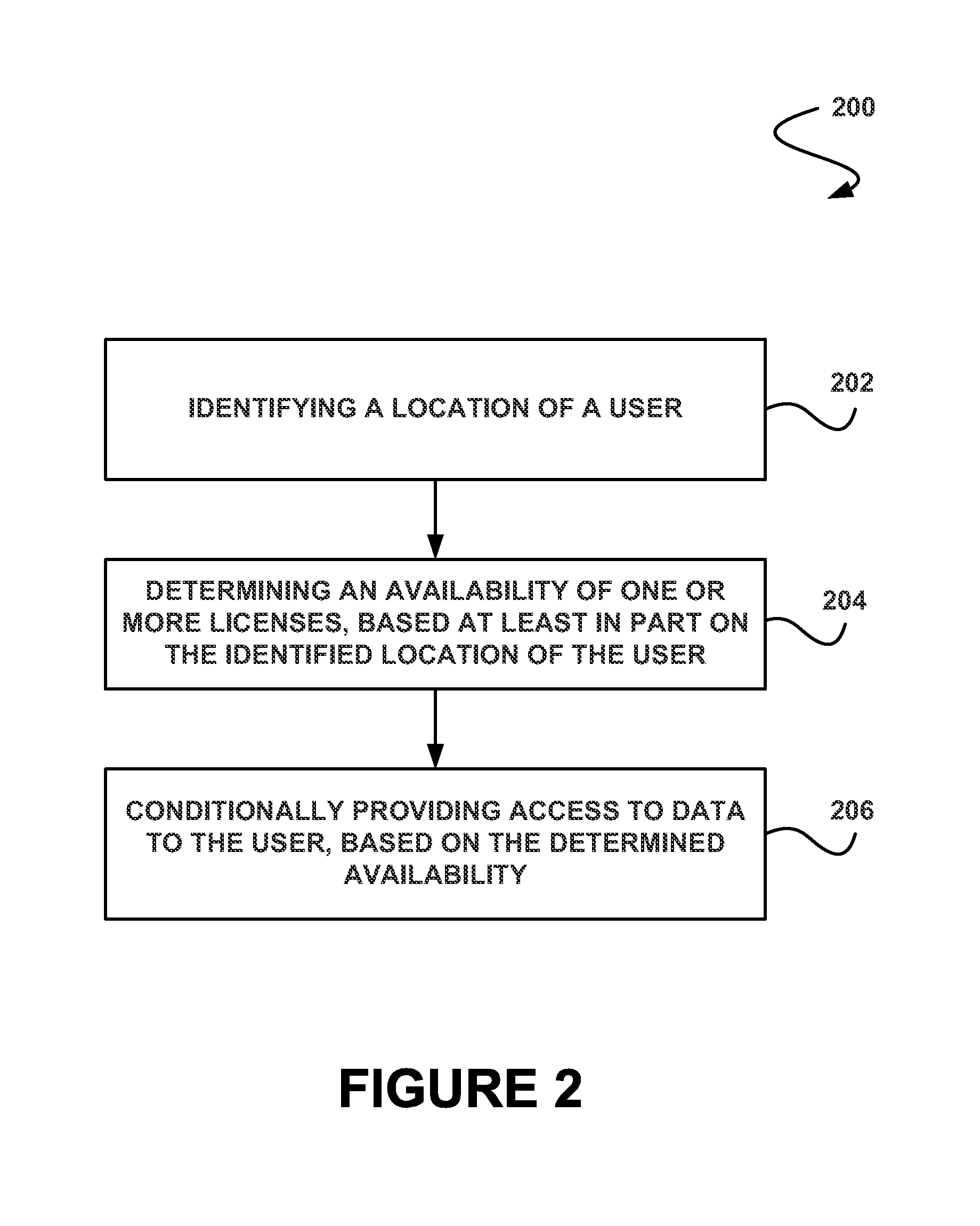

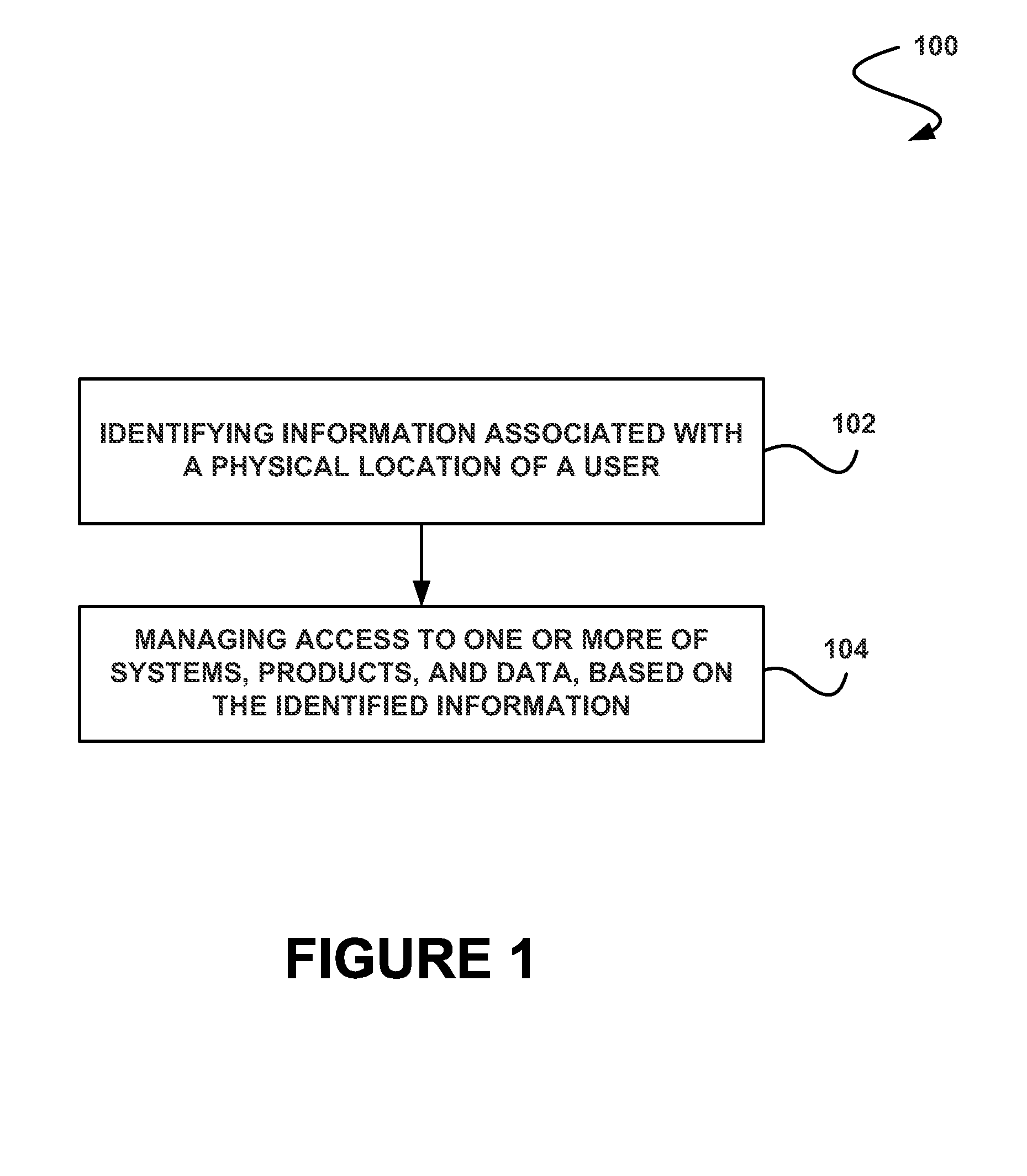

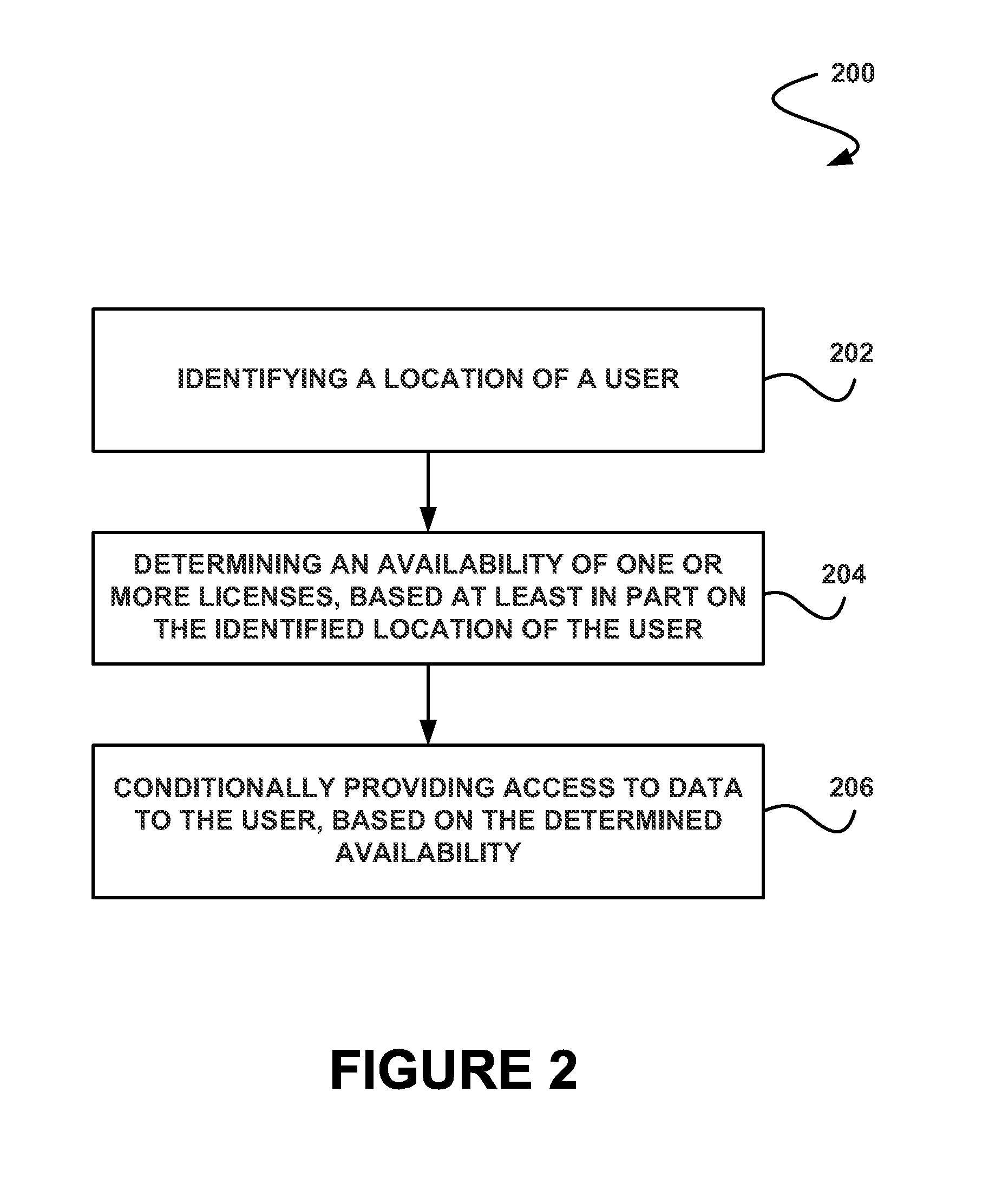

System, method and computer program product for managing access to systems, products, and data based on information associated with a physical location of a user

ActiveUS20140304784A1Improve Data Management EfficiencyEnhanced data management accuracyDigital data processing detailsMultiple digital computer combinationsData managementManagement efficiency

In accordance with embodiments, there are provided mechanisms and methods for managing access to data based on information associated with a physical location of a user. These mechanisms and methods for managing access to systems, products, or data based on information associated with a physical location of a user can enable improved data management efficiency, enhanced data management accuracy, decreased data management costs, decreased licensing costs, increased security, additional marketing opportunities, etc.

Owner:SALESFORCE COM INC

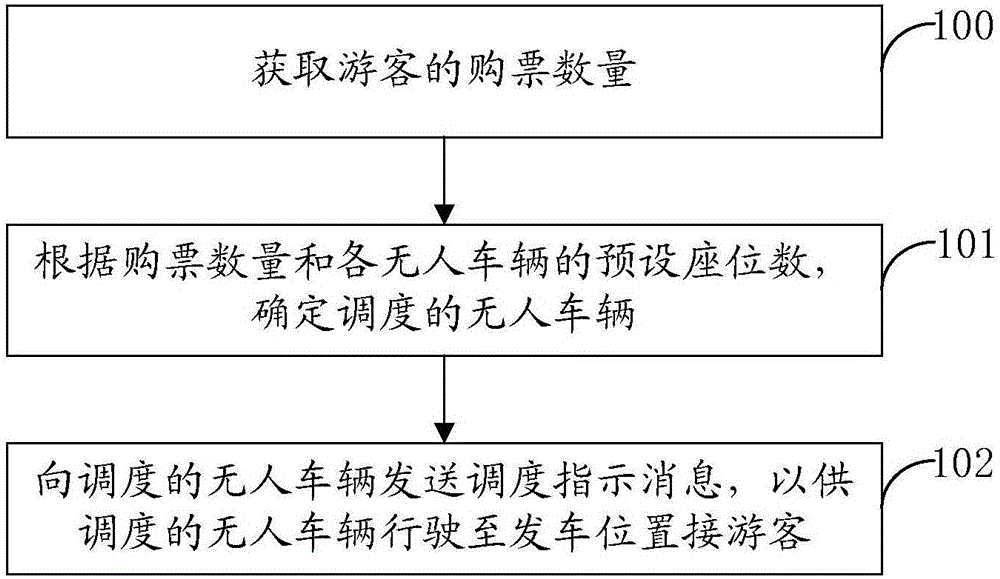

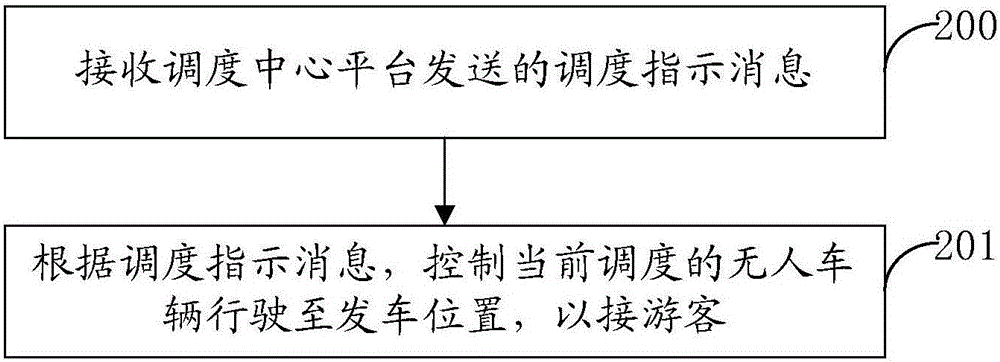

Unmanned vehicle management method and system, dispatching center platform and unmanned vehicle

InactiveCN106228303AReduce labor operating costsImprove work efficiencyTicket-issuing apparatusRegistering/indicating working of vehiclesOperational costsVehicle driving

The invention provides an unmanned vehicle management method and system, a dispatching center platform and an unmanned vehicle. The method comprises the steps that the ticket number of tourists is acquired; a dispatching unmanned vehicle is determined according to the ticket number and the preset seat number of each unmanned vehicle; and a dispatching indication message is transmitted to the dispatching unmanned vehicle so that the dispatching unmanned vehicle is enabled to be driven to the departing position to pick up the tourists. With application of the technical scheme, automatic dispatching of the unmanned vehicle can be realized with no requirement for manual dispatching or manual vehicle driving so that manual operation cost of scenic spots can be effectively saved, the management precision of the infrastructures in the scenic spots can be greatly enhanced through management and control of the dispatching center platform for the unmanned vehicle, the working efficiency of operation of the scenic spots can be effectively enhanced and visiting interest and tourism experience of the tourists can be enhanced.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

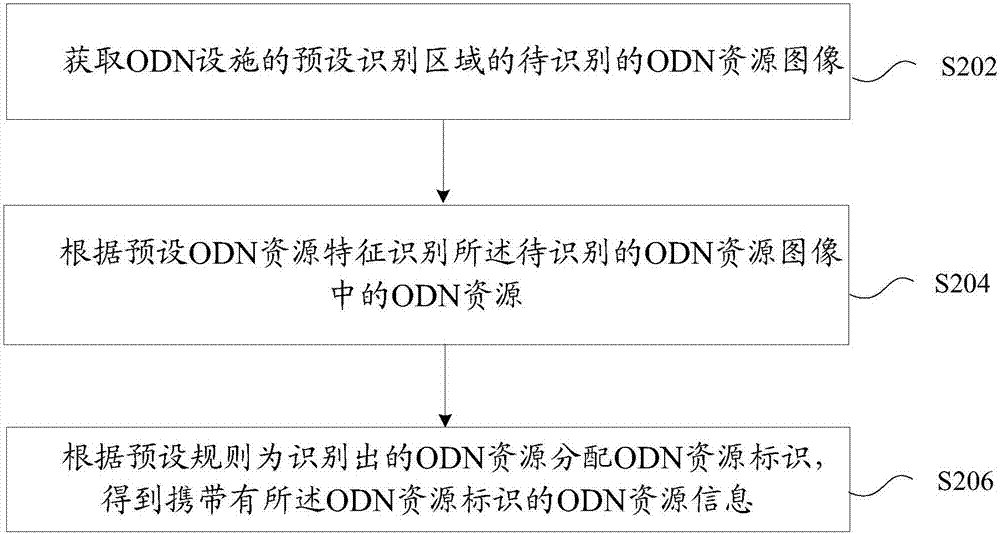

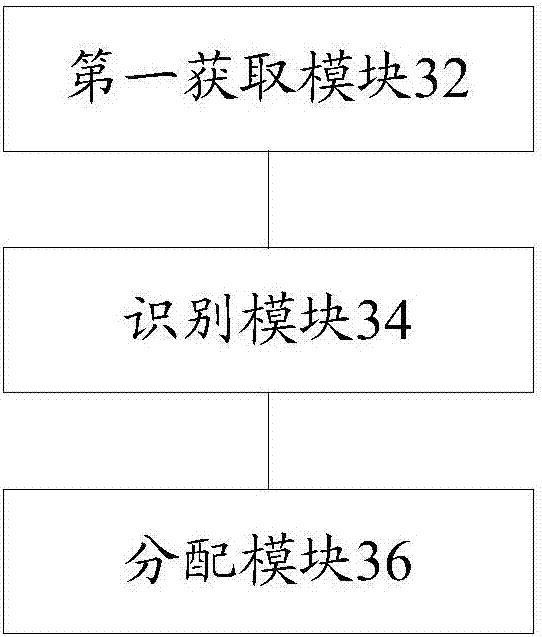

Optical distribution network ODN resource information collection method and apparatus

ActiveCN107465528ARealize unified managementImprove management accuracyData switching networksResource informationResource management

The invention provides an optical distribution network ODN resource information collection method and apparatus. The method comprises the following steps: obtaining a to-be-identified ODN resource image of a preset identification area of an ODN facility; identifying ODN resources in the to-be-identified ODN resource image according to a preset ODN resource feature; obtaining ODN resource information carrying the ODN resource identifier according to an ODN resource allocation ODN resource identifier according to a preset rule, wherein the ODN resource identifier is used for uniquely identifying the identified ODN resource. The problem of low ODN resource management accuracy in related art is solved, unified ODN resource management is realized, and the ODN resource management accuracy is improved.

Owner:ZTE CORP

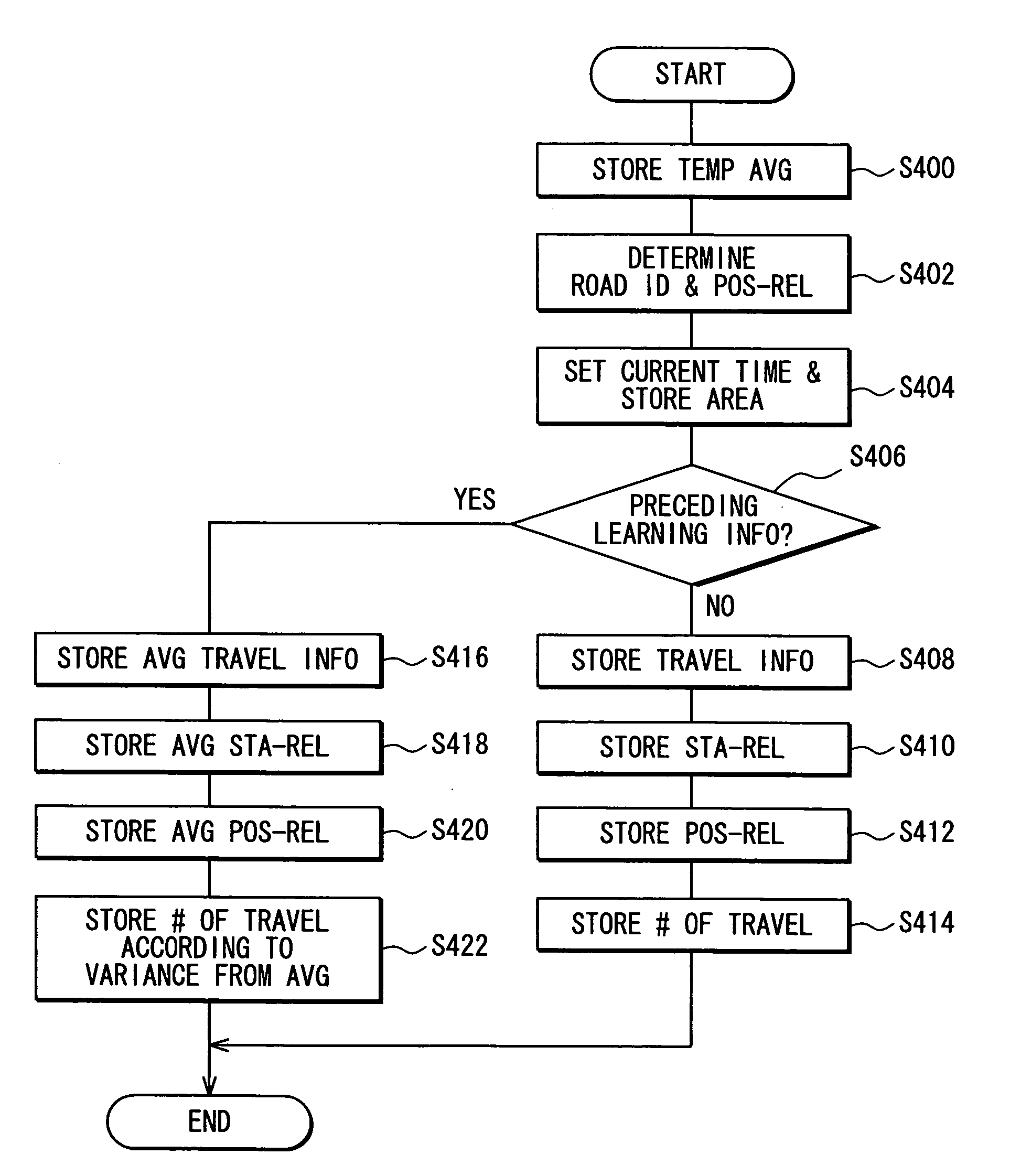

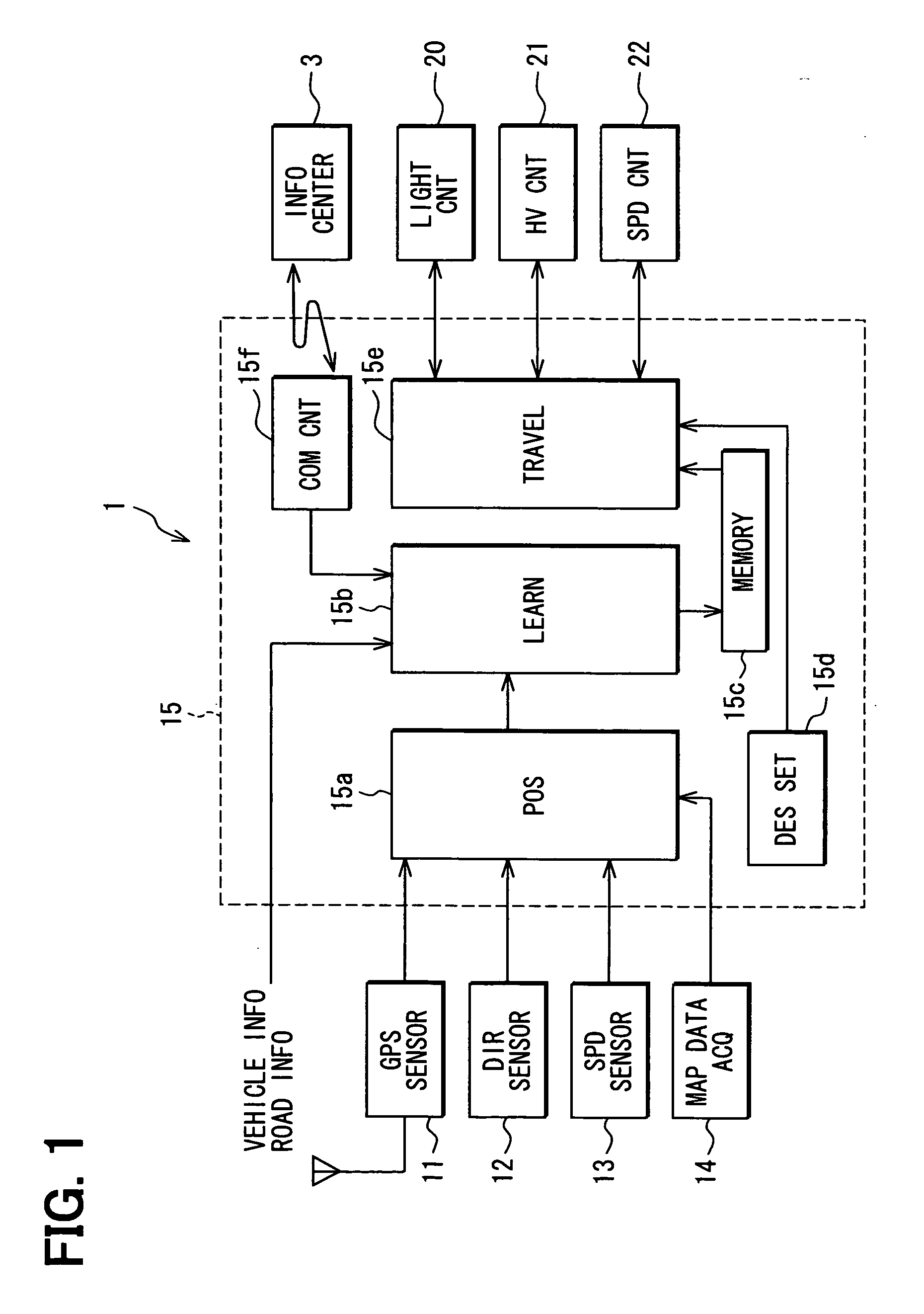

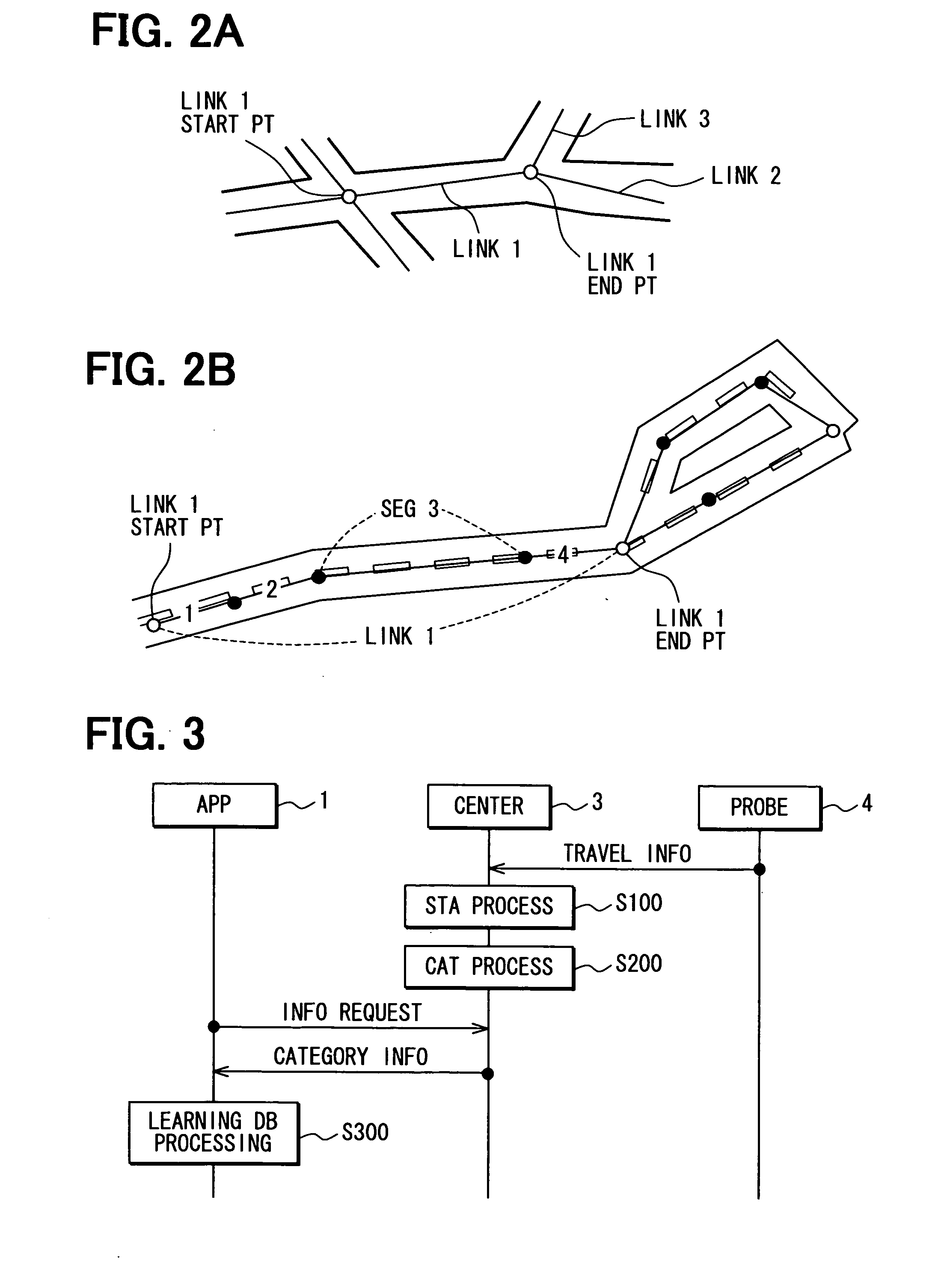

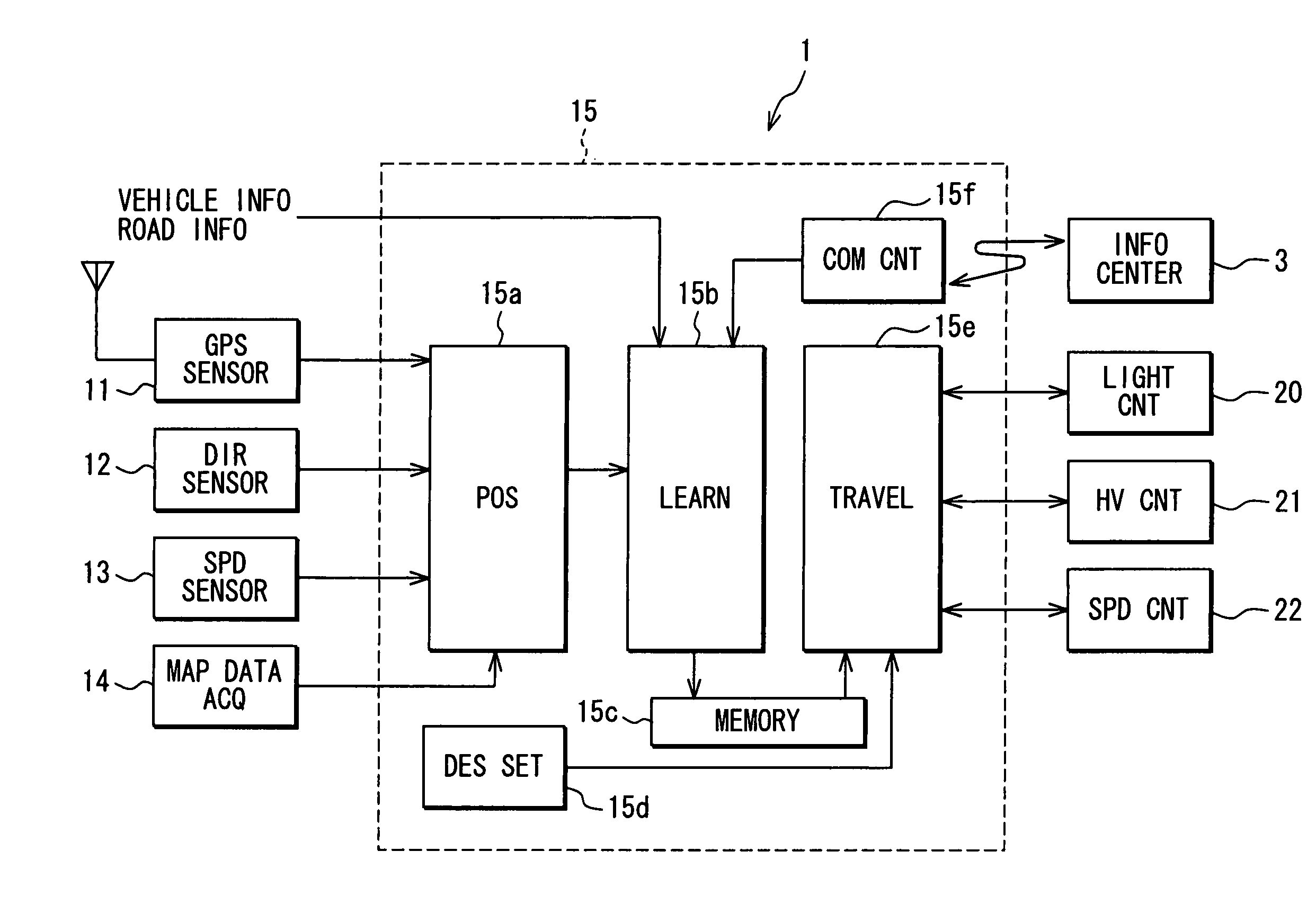

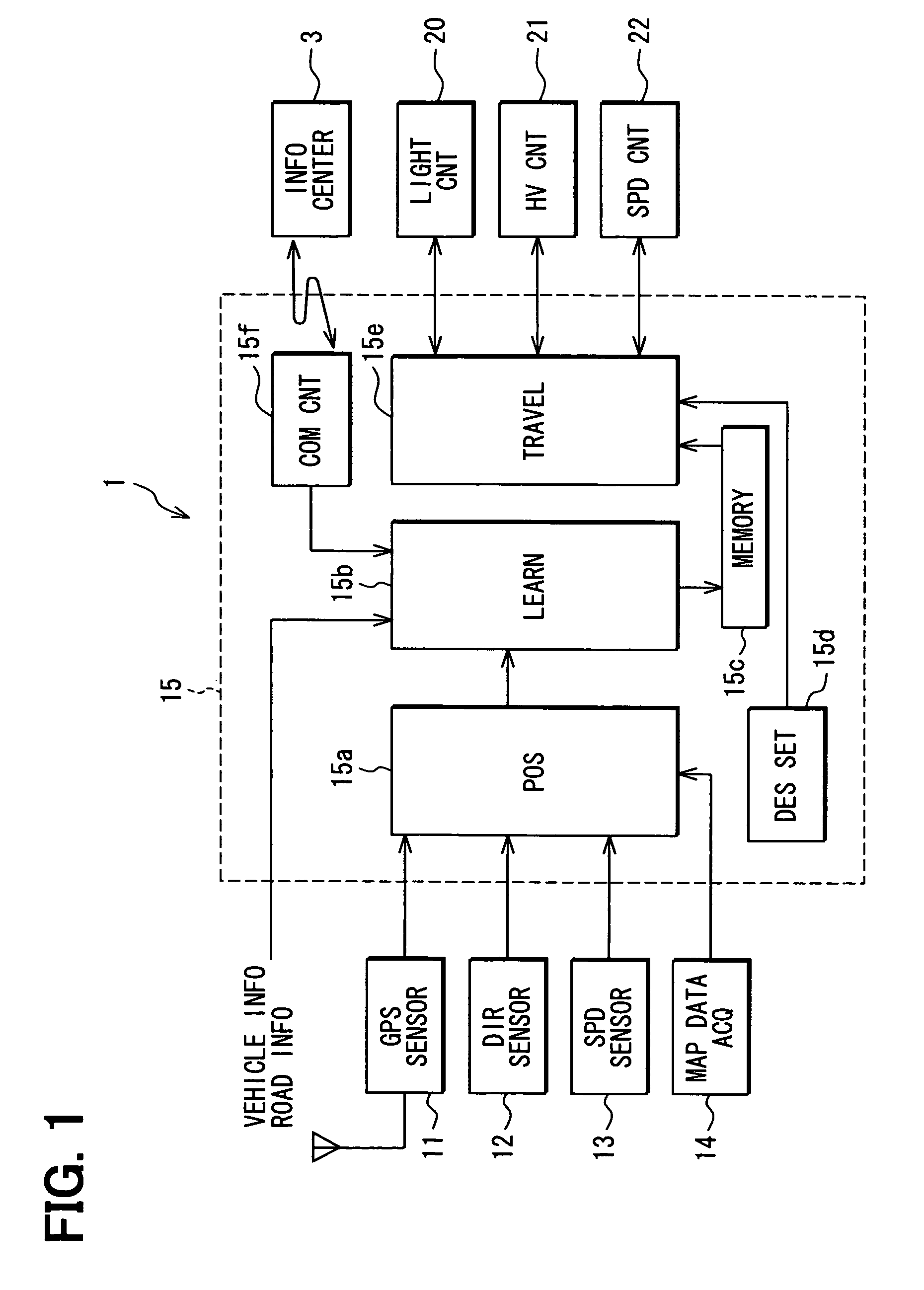

Travel information collection apparatus

InactiveUS20080269985A1Easy and precise managementWay accurateDigital data processing detailsRoad vehicles traffic controlTraffic capacityInformation Harvesting

Travel information is categorized into plural time slot categories according to information characteristics of traffic flow information that represents a traffic flow of each of road sections in a database of an information center, and a learn database is built for each of the categories derived from above categorization. The travel information collected by a travel of a self vehicle along the road sections is learned according to the categories of the learn database for accurately managing the travel information according to the characteristics of the traffic flow.

Owner:DENSO CORP

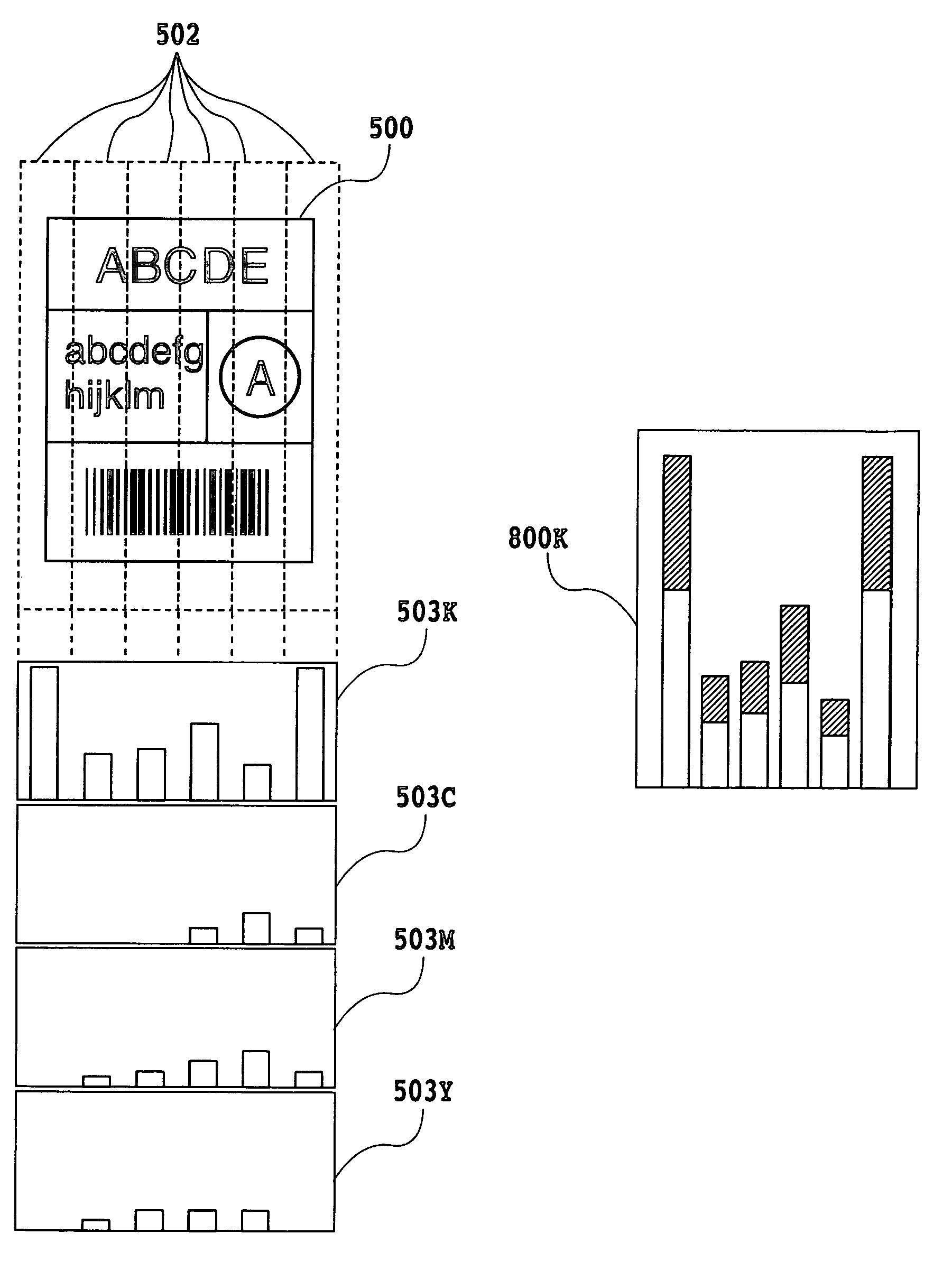

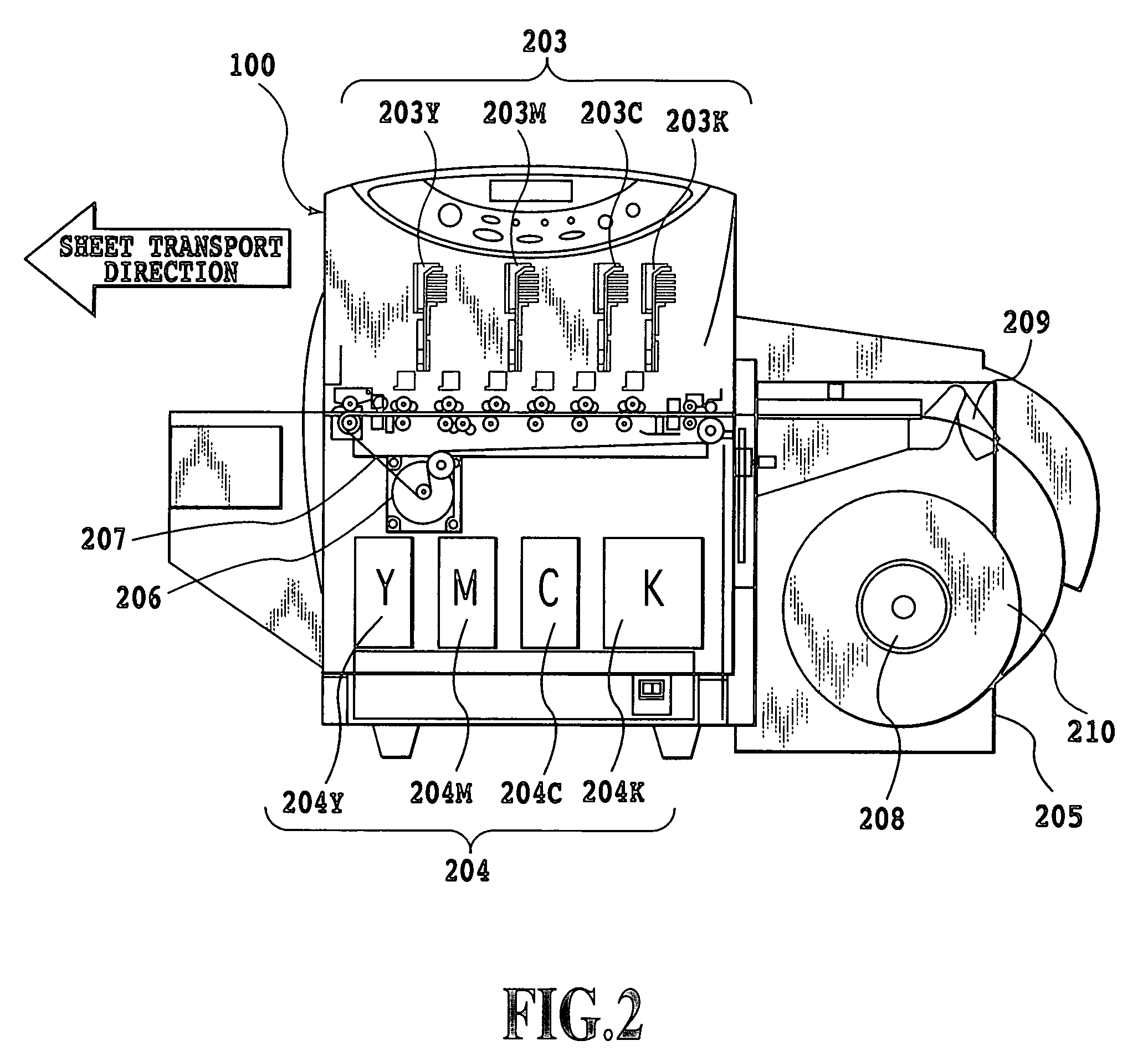

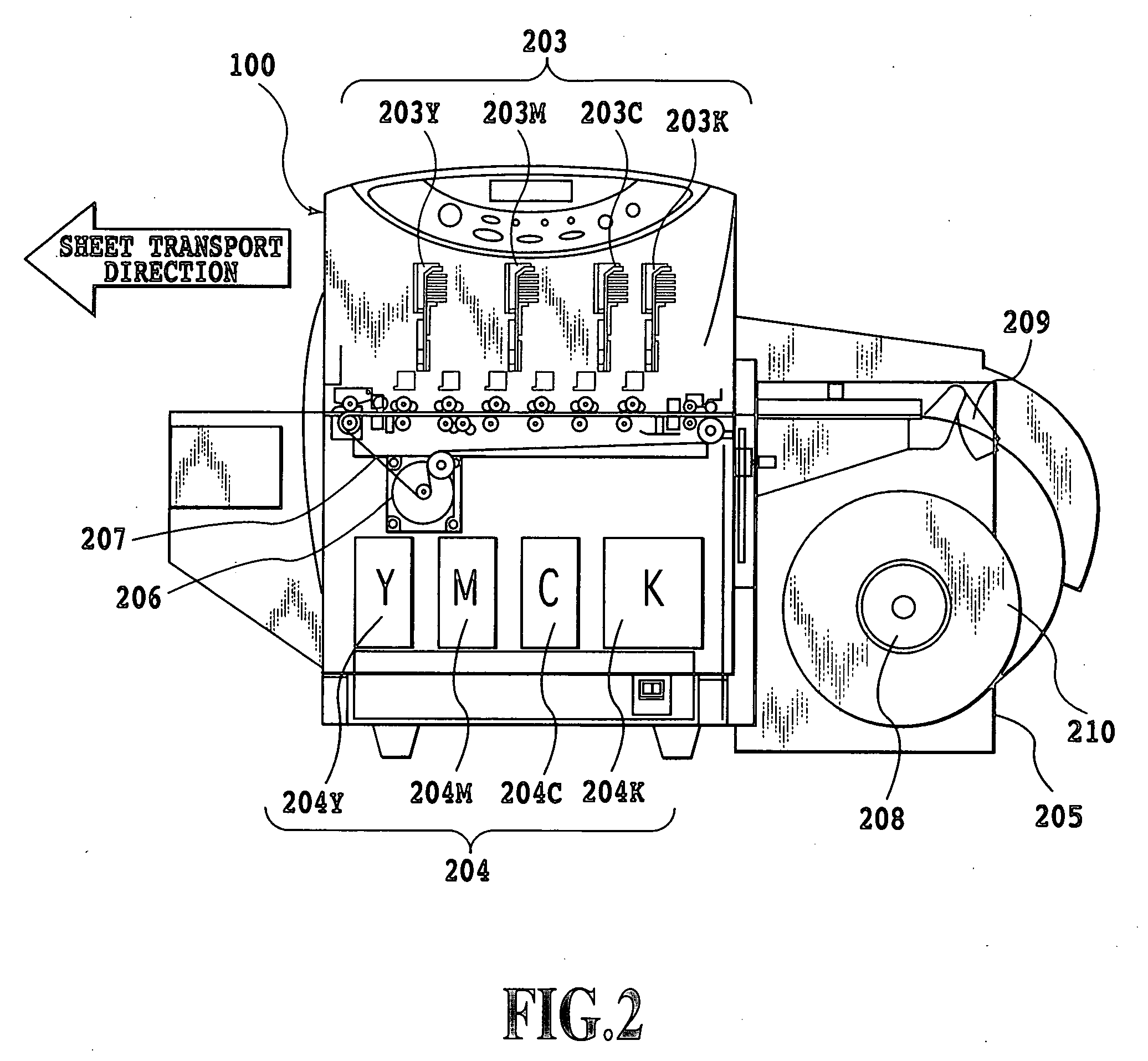

Printing apparatus and image processing apparatus

InactiveUS7717534B2Accurate informationAccurate service lifeOther printing apparatusInformation processingImaging processing

Owner:COPYER

Method for controlling hot-rolled thin-specification strip steel coil shape

ActiveCN108817089AAvoid badCalibration method is simpleRoll mill control devicesMetal rolling arrangementsLoop controlEconomic benefits

The invention discloses a method for controlling the hot-rolled thin-specification strip steel coil shape. The method is specifically characterized in that the centering deviation of a front side guide plate of a coiling machine is less than or equal to 3 mm, and the parallelism degree is smaller than or equal to 5 mm / m; a pinch roll is calibrated to be started at the rolling position, and the small-pressure dynamic calibration is carried out; the clearance deviation of a transition plate is smaller than or equal to 2 mm, and the abrasion depth is less than or equal to 10 mm; the calibration of a wrapper roll adopts open loop control, the deviation of roll gaps at the two sides is less than or equal to 0.5 mm, and the gap relative to an arc-shaped plate is less than or equal to 3 mm; a first step reduction position given protection function is adopted when the wrapper roll performs stepping control; the thickness error compensation of the strip steel in the coiling diameter calculationis limited within 3 mm; and the coiling machine adopts a tail automatic tail setting protection function, and the strip steel enters the tail setting mode when the tail of the strip steel is 100 m away from the coiling machine. According to the method, the coiling process and the management precision of coiling equipment are controlled, so that the problems of poor roll shape can be effectively solved, and the good economic benefits are achieved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

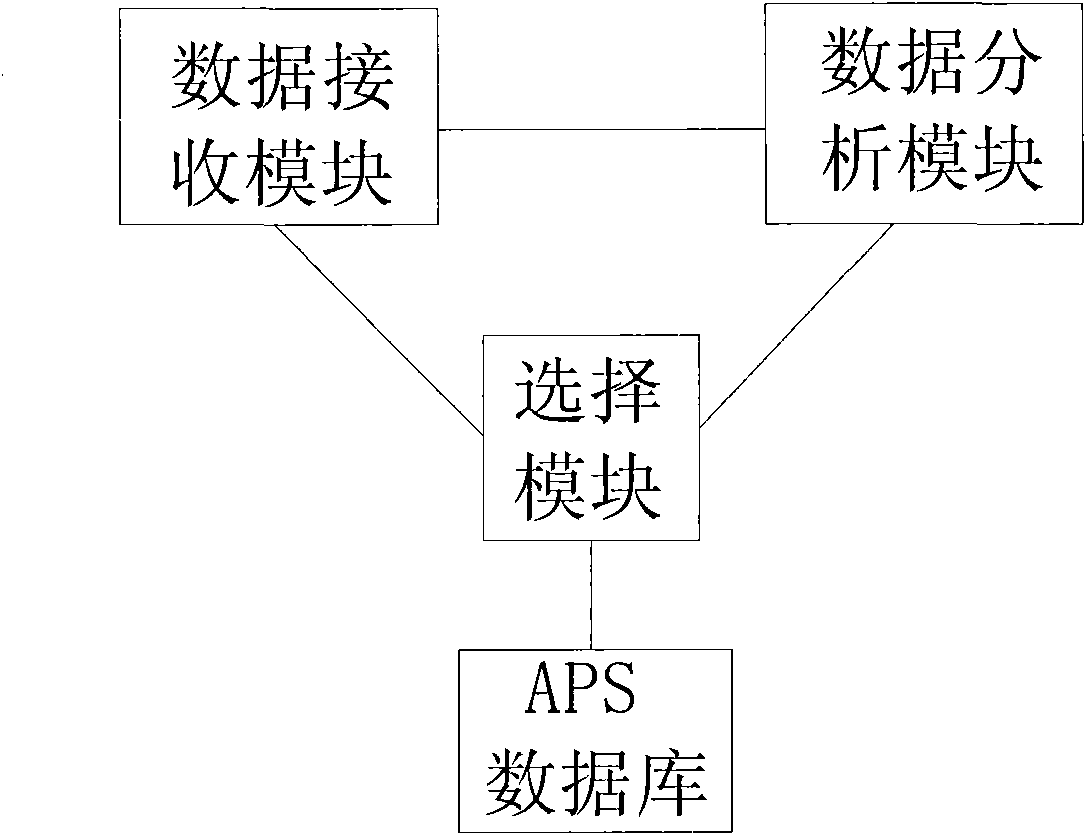

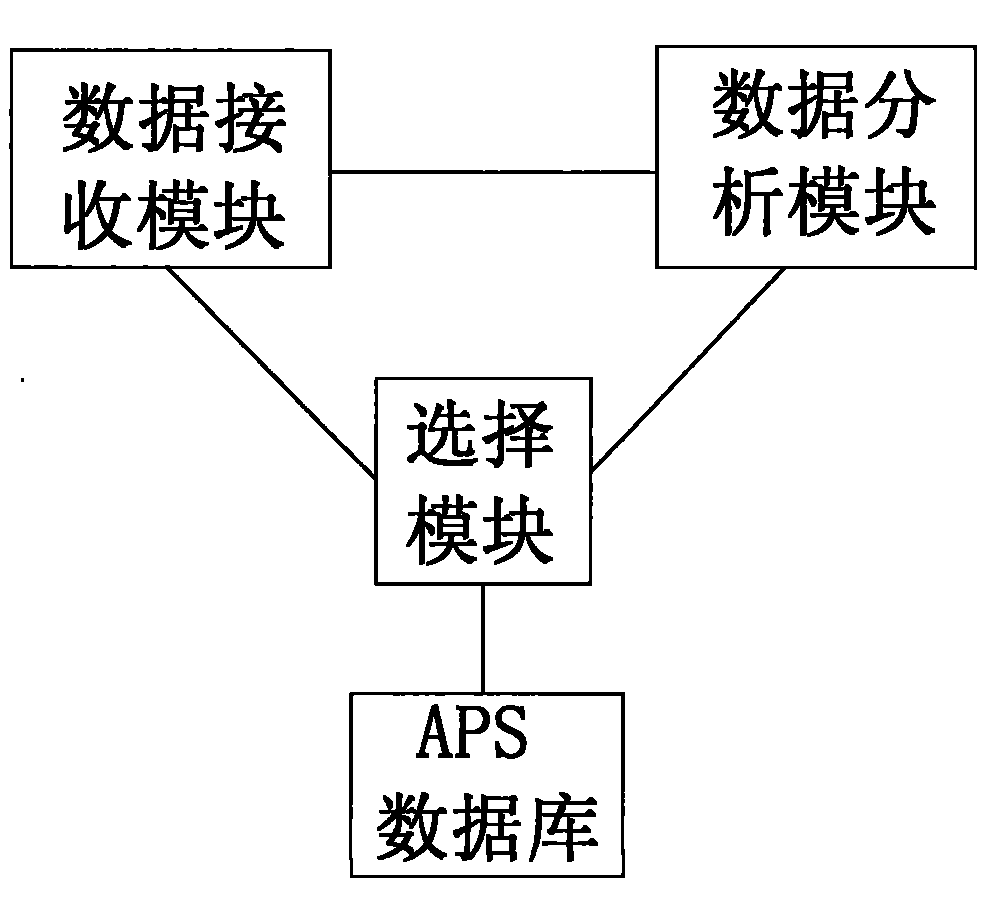

Advanced planning and scheduling system

InactiveCN102117434AOptimize production planIncrease production capacityResourcesManagement processAdvanced planning and scheduling

The invention relates to an advanced planning and scheduling system. The advanced planning and scheduling system comprises a selection module, a data receiving module and a data analysis module which are mutually and respectively connected. Therefore, the system can be used for monitoring the difference of data tables in various versions and recording and tracking the execution result of the advanced planning and scheduling system so as to operate history data and further continuously execute the imported efficiency analysis of the advanced planning and scheduling system, to be convenient for a planner to adjust modeling parameters or change the management flow according to the condition, and to ensure that the advanced planning and scheduling system can gradually approach to the execution result.

Owner:QINGDAO PENGHAI SOFT CO LTD

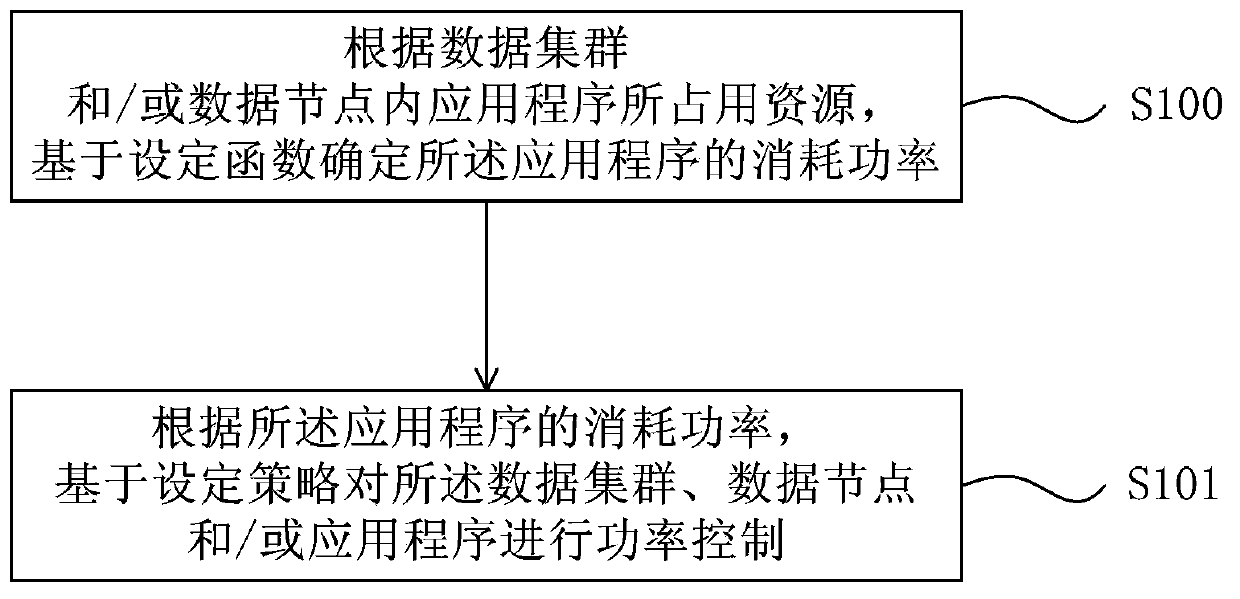

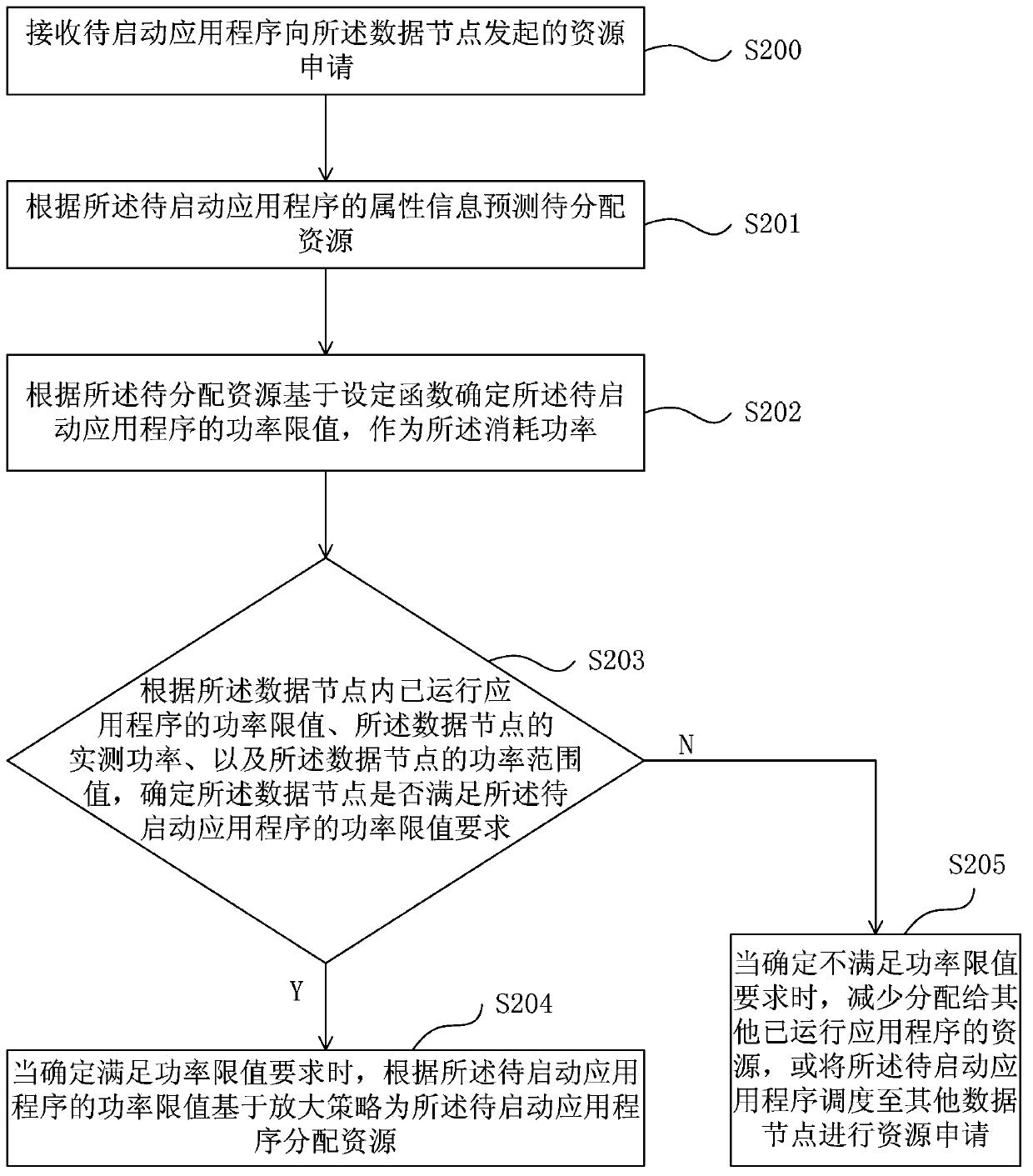

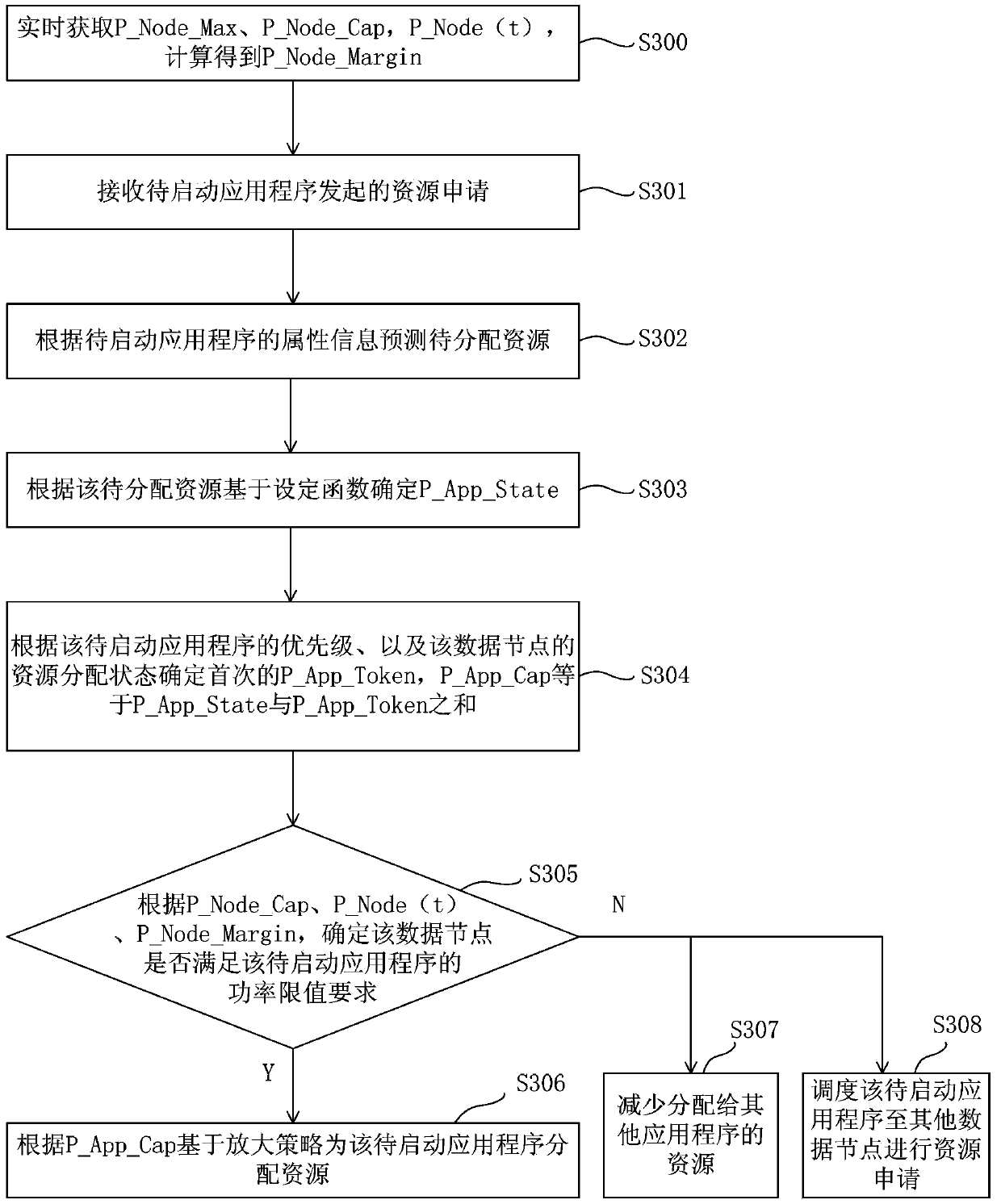

Power control method and device for data system

ActiveCN103389791AImprove management accuracyEnergy efficient ICTHardware monitoringData systemEmbedded system

Then embodiment of the invention provides a power control method and a power control device for a data system. The power control method for the data system comprises the following steps of determining the consumed power of application programs based on a set function according to the occupied resource of application programs in a dataset group and / or a data node; and carrying out power control on the dataset group, the data node and / or the application programs based on a set strategy according to the consumed power of the application programs. The power control method provided by the embodiment of the invention can be used for carrying out the power control on different application programs, and the management precision is high.

Owner:HUAWEI TECH CO LTD

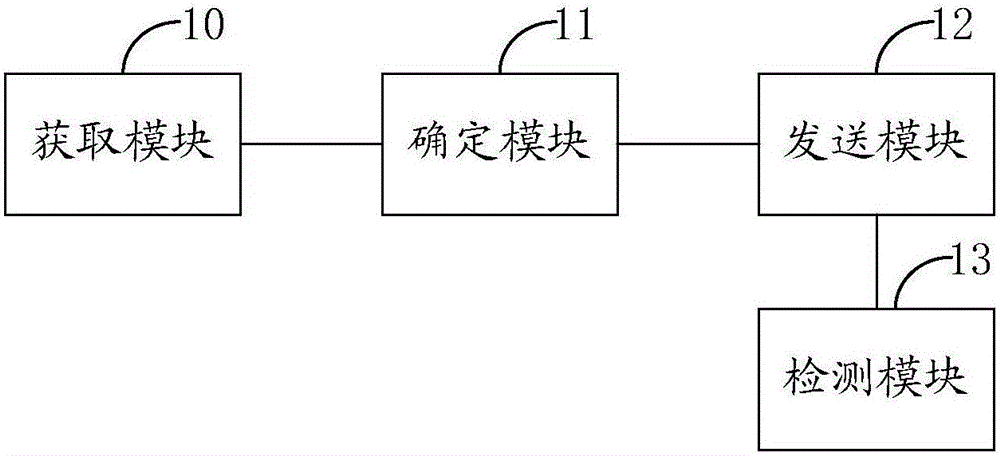

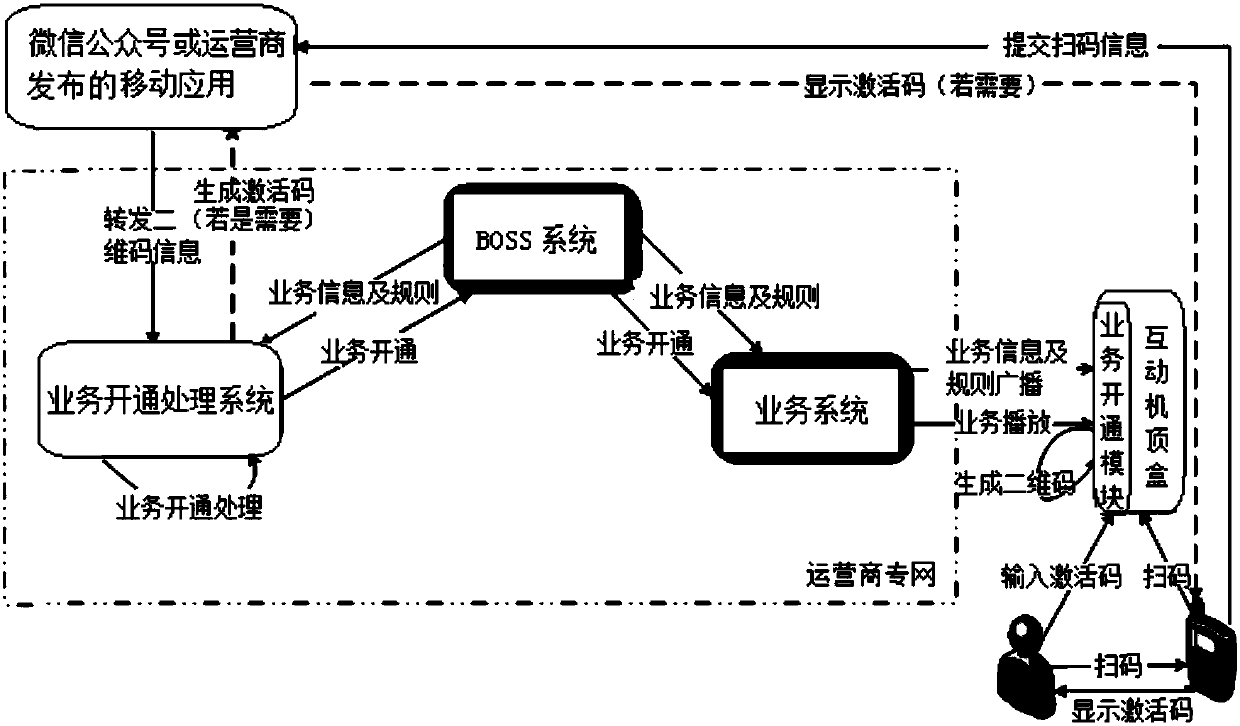

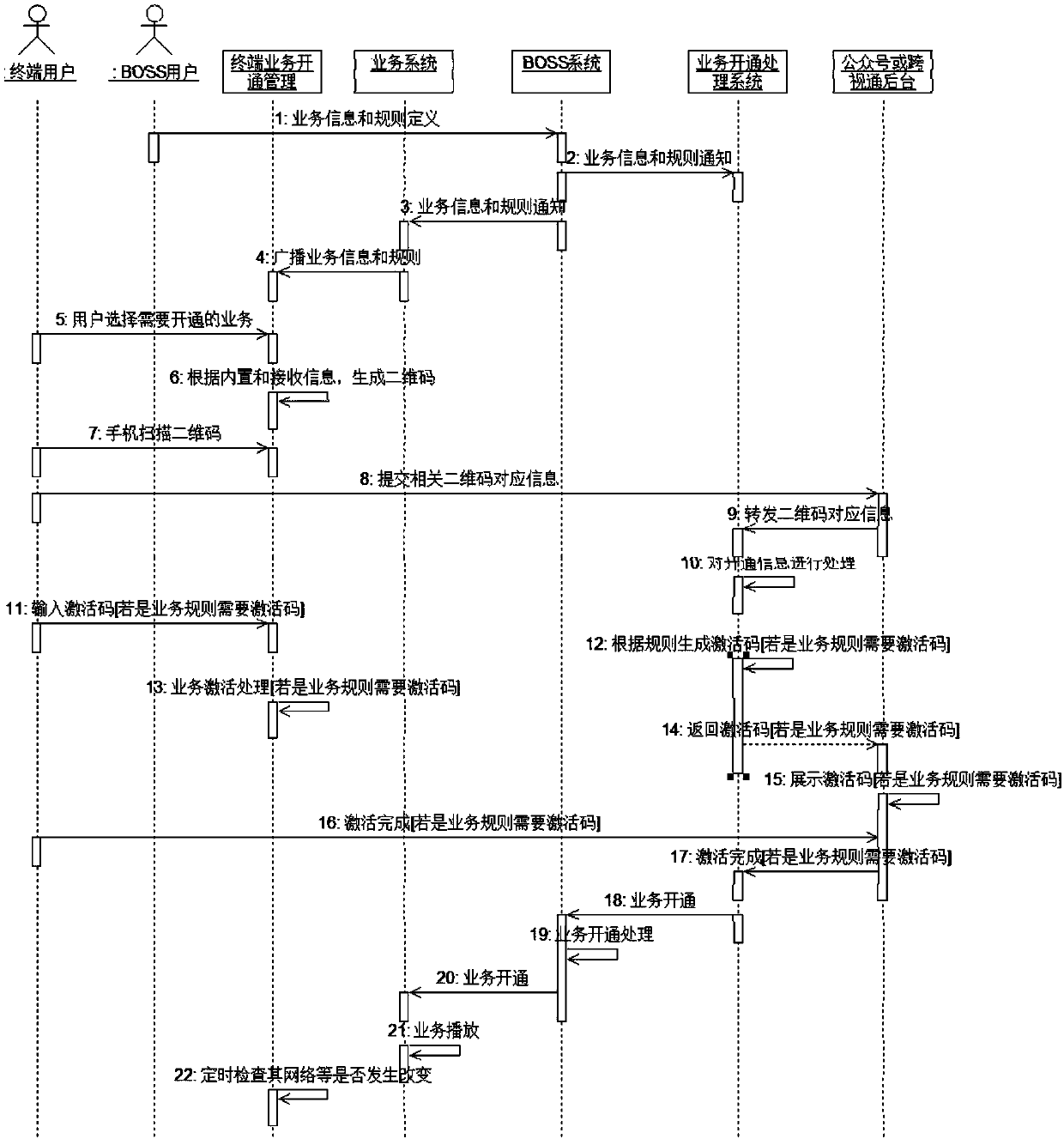

Two-dimensional code and mobile application combined service fulfillment method

InactiveCN107613346AReal-time activationLow costDigital data authenticationSelective content distributionDigital signatureService experience

The invention relates to a two-dimensional code and mobile application combined service fulfillment method. A two-dimensional code is combined with a mobile application to fulfill a service in real time, so that a service process is shortened, and enterprise cost during a service fulfillment process is reduced; with the aid of the two-dimensional code and the mobile application, real-time servicefulfillment under a unidirectional broadcast network environment is achieved, and service experience of a user is enhanced; a service fulfillment application of the terminal can periodically collect current network information, if the user performs a telephone relocation behavior without authorization, the behavior can be detected, and thus the unauthorized telephone relocation behavior is reduced; service fulfillment information is reported to BOSS periodically, the phenomenon that an operation staff reports in advance or delays report in the past is avoided, user dispute is reduced, and service management accuracy of an operator is improved; due to the methods that current time information is added into the two-dimensional node to perform encryption or generate an encrypted digital signature, and an activation code is input into the terminal, the phenomenon that the user maliciously imitates the service fulfillment information is reduced or avoided, and unnecessary loss of the user and the enterprise is avoided.

Owner:ORIENTAL CABLE NETWORK

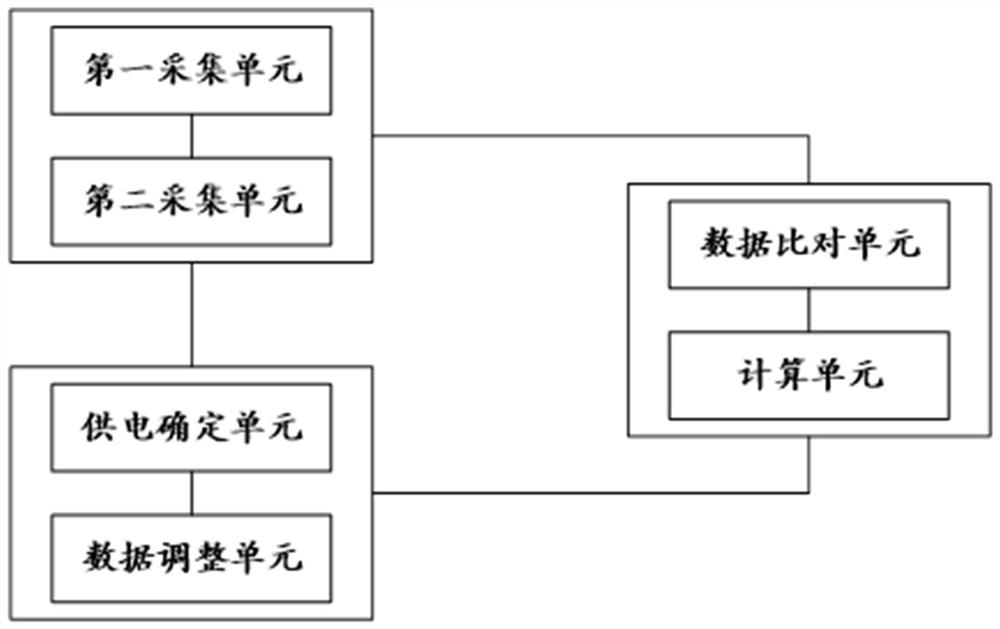

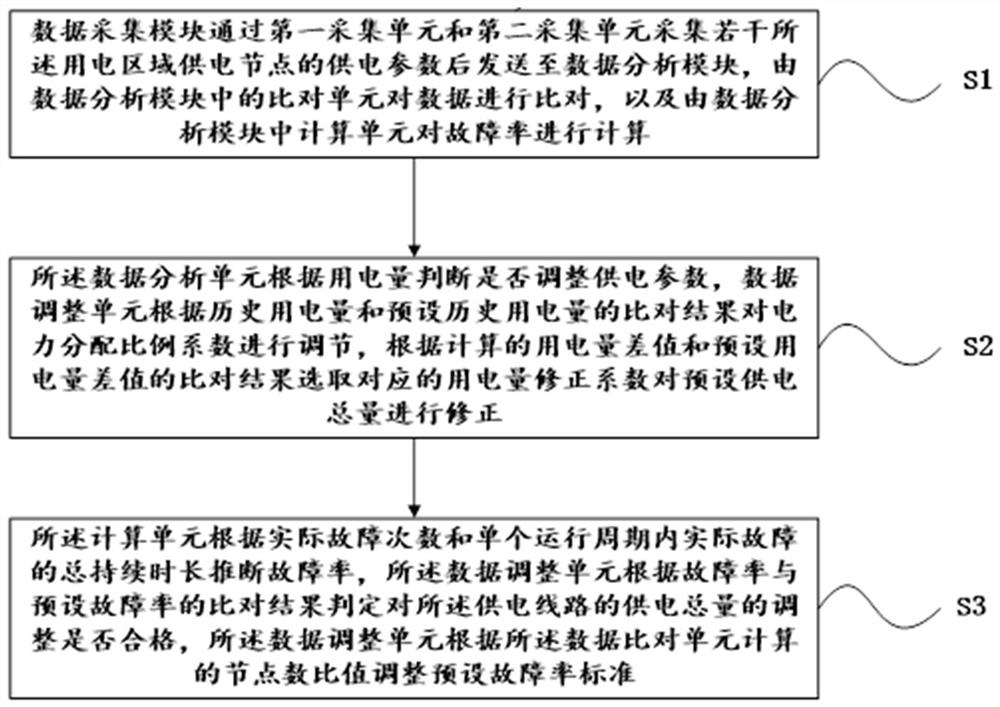

Digitized smart power grid area management system and method

ActiveCN114444739AImprove management accuracyImprove efficiencyData processing applicationsCircuit arrangementsData acquisitionData acquisition module

The invention relates to the technical field of electric power, in particular to a digitized intelligent power grid area management system and method, and the system comprises a data collection module which comprises a first collection unit and a second collection unit which are used for collecting parameters and faults; the data analysis module is connected with the data acquisition module and comprises a data comparison unit for comparing the power supply parameters and a calculation unit for calculating the fault rate; the power supply control module is connected with the data acquisition module and the data analysis module and comprises a power supply determination unit for determining the power supply quantity and a data adjustment unit for adjusting parameters; the data comparison unit compares the parameters and adjusts the electric quantity and the distribution proportionality coefficient, adjusts the distribution proportionality coefficient or selects a correction coefficient according to the historical electric quantity and a comparison result during adjustment, deduces the failure rate according to the failure frequency and duration during failure, judges whether the adjustment is qualified or not according to the comparison result, and judges whether the adjustment is unqualified or not according to the comparison result. And the data comparison unit compares the node number ratio to adjust the preset fault rate, so that the management precision of the system is improved.

Owner:GUANGDONG POWER GRID CO LTD

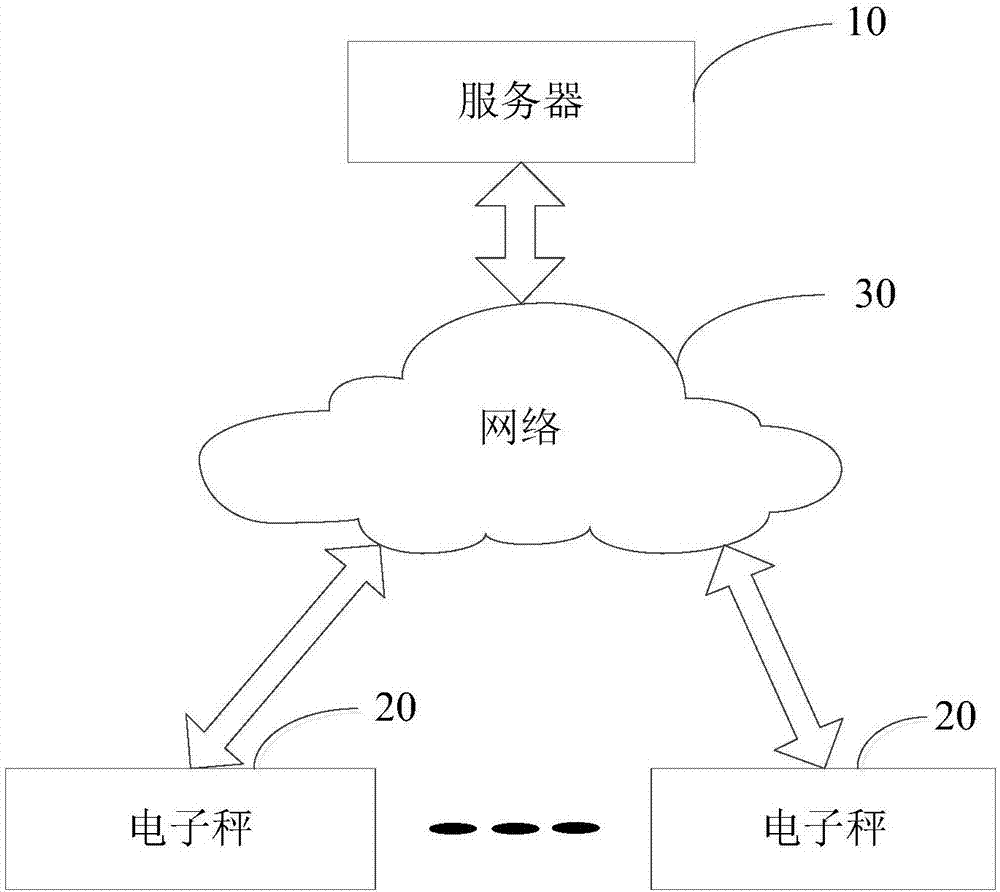

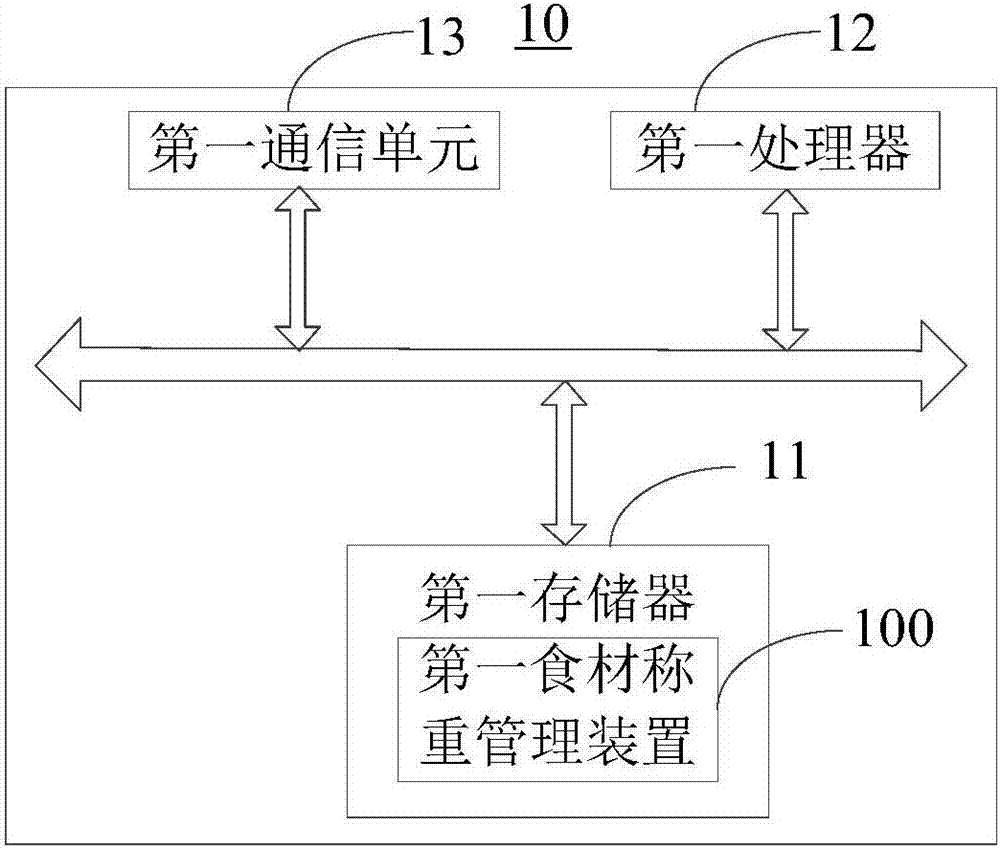

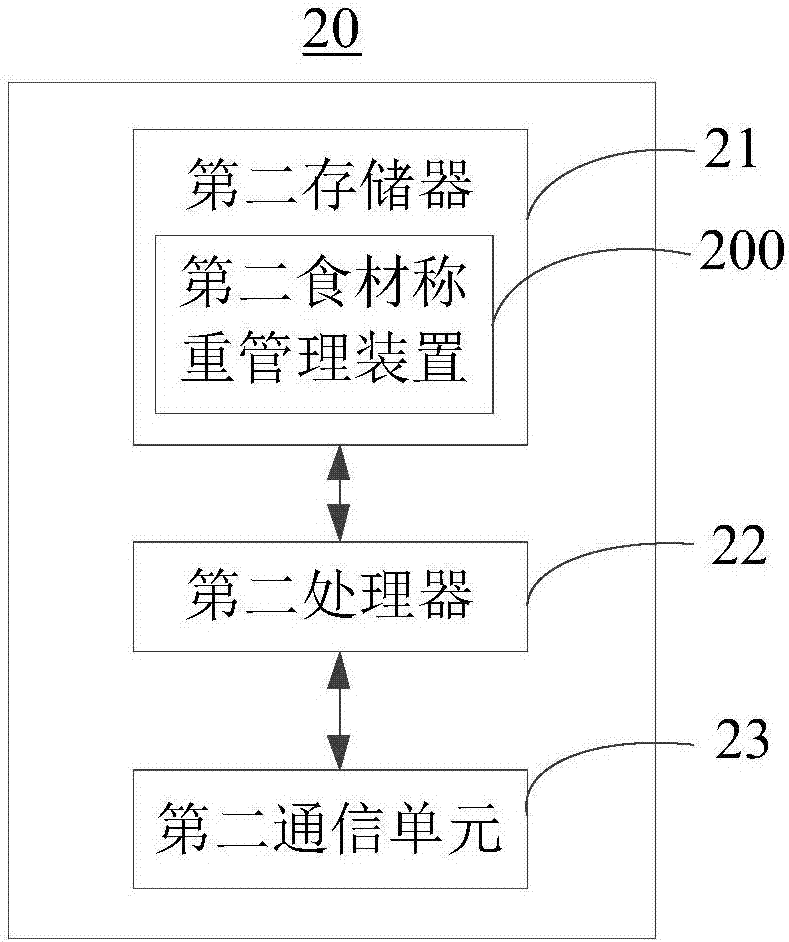

Food material weighing management method and device

InactiveCN107977881AReduce error rateReduce procurement omissionsBuying/selling/leasing transactionsPoint-of-sale network systemsOrder formFood material

The present invention provides a food material weighing management method and device. The method comprises the steps that: a server obtains a food material order to be weighed, performs order divisionprocessing of the food material order to be weighed according to a food material variety division rule and correspondingly generates at least one weighing order; the server correspondingly sends eachgenerated weighing order to at least one electronic scale; each electronic scale receives each weighing order sent by the server, performs reading identification of the order content of each weighingorder and obtains weight information of each food material single item in each weighing order; and the electronic scale performs weighing of each food material single item in each weighing order, records the weighing information of the weighed food material single items and displays the completion condition of each weighing order according to the recorded weighing information. The food material weighing management method is low in error rate and high in management precision, can reduce the appearance probability of a food material purchasing omission problem, can reduce the checking workloadof food material purchase personnel and can improve the food material purchase personnel experience.

Owner:四川瑞斯佳宴科技有限公司

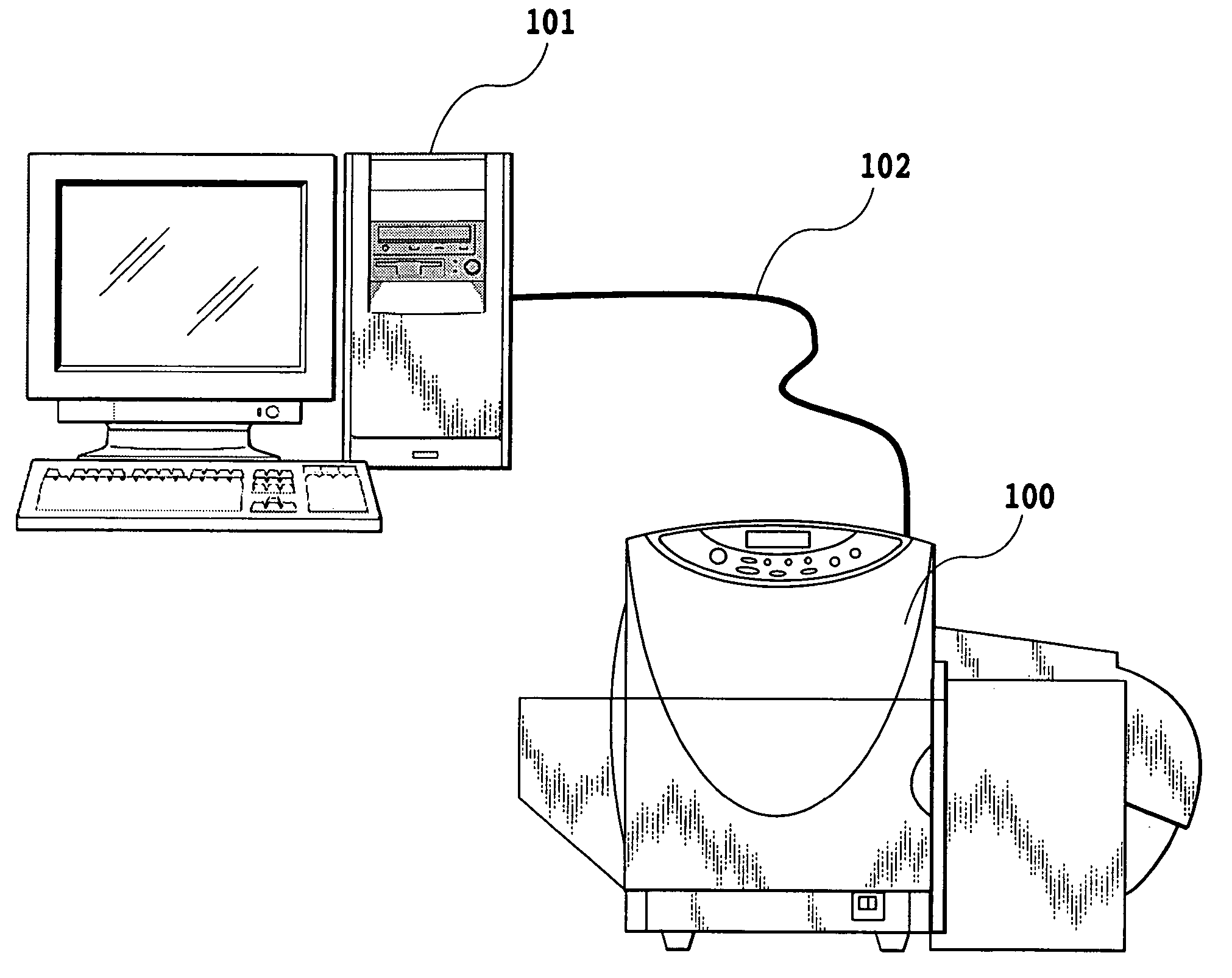

Printing apparatus and image processing apparatus

InactiveUS20060214969A1Efficiently manageImprove management accuracyOther printing apparatusHead partsNozzle

This invention provides a printing apparatus and an information processing apparatus which can process precise information on the number of pixels printed by nozzles of the print head without degrading throughput and properly manage the service life of the print head. To this end, a plurality of nozzles of the print head are divided into a plurality of blocks and a nozzle in each of the blocks which prints a maximum number of pixels in a predetermined unit print volume is taken to be a representative nozzle. In each of the blocks, the numbers of pixels printed by the representative nozzle for every unit print volume are accumulated and managed.

Owner:COPYER

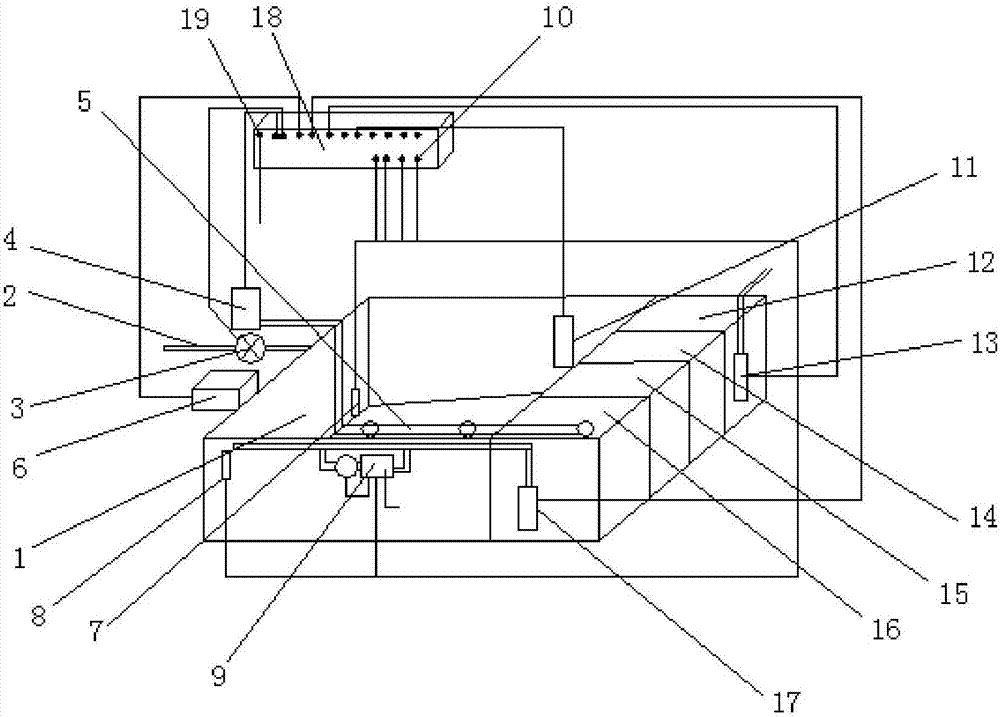

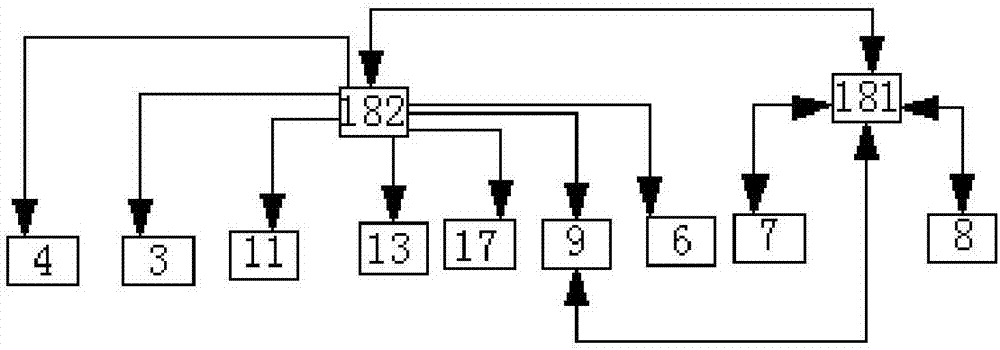

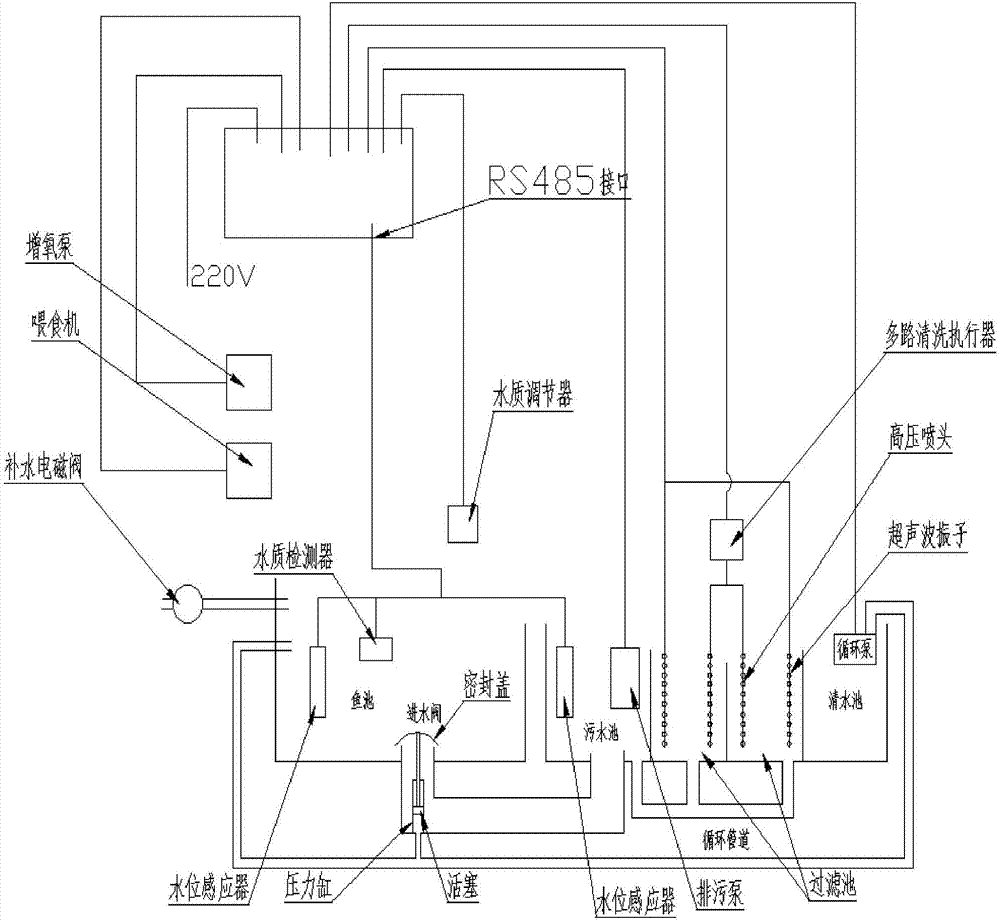

Intelligent landscape fish pond system with automatic cleaning function

ActiveCN107047446AAutomatically adjust the water levelAutomatically adjust water qualityClimate change adaptationPisciculture and aquariaAeration systemSolenoid valve

The invention discloses an intelligent fish pond system with an automatic filtering and cleaning system. The intelligent fish pond system comprises a control host, a circulating pump, an automatic feeding system, an aeration system, a water supply solenoid valve, a water supply level sensor, a drainage level sensor, a water quality sensor, a water quality regulation system, an automatic filtration system, an automatic filter-pond cleaning system, a water supply sensor and a drainage sensor. Information of the water quality sensor is transmitted to the control host through an RS485 interface, and after program operation, a control-end module performs intelligent control on all actuators. Through the fish pond system, management accuracy is enhanced through intelligent automatic management, manpower is saved, and the fish pond is cleaned and filtered automatically.

Owner:南京铭发智能科技有限公司 +1

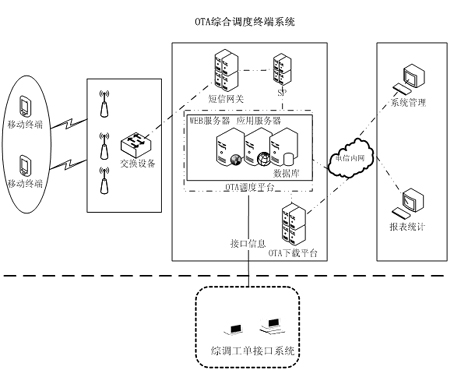

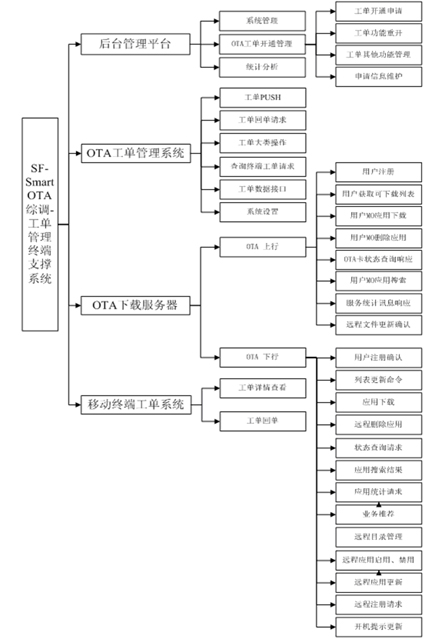

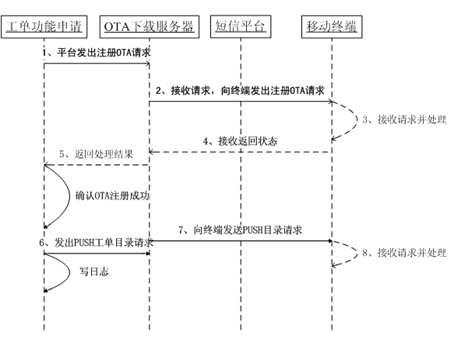

OTA over the air technology-based integrated dispatch terminal support system working method

InactiveCN101937533ALow costGuaranteed working hoursData processing applicationsTransmissionSupporting systemComputer terminal

The invention discloses an OTA over the air technology-based integrated dispatch terminal support system working method. The integrated dispatch terminal support system comprises an OTA download server, an OTA work order management sub-system, an OTA backstage management sub-system and a mobile terminal work order sub-system. The method comprises the following steps: a cell manager can perform corresponding work order searching, work order receipt and other operations on a mobile terminal after starting the OTA function; the integrated dispatch terminal support system has no any restriction on the mobile terminal, and the whole work order is shown in a menu mode, has simple operation and convenient use, coexists with the original work order system without influencing application of the original work order system, and provides a novel and effective work order searching mode.

Owner:成都四方信息技术有限公司

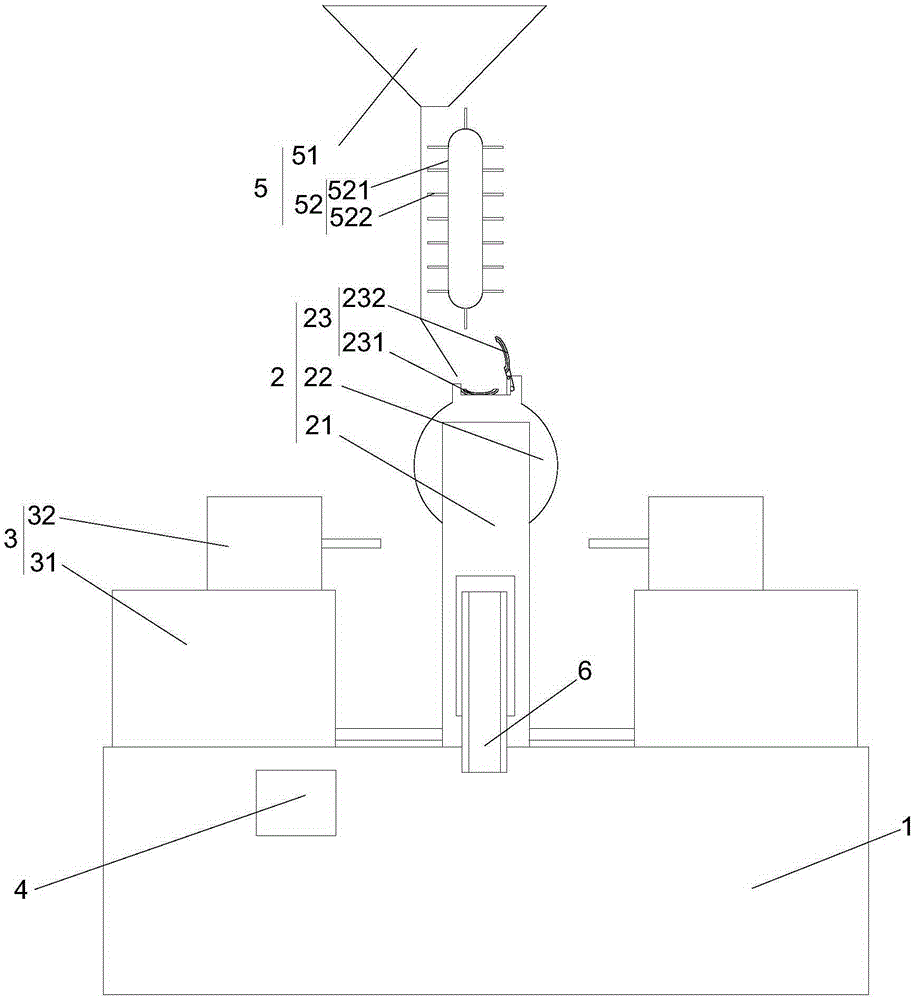

Practical bi-directional drill machine tool

InactiveCN106624018AEasy to recycleEasy to operateWork clamping meansPositioning apparatusEngineeringMachine tool

The invention provides a practical bi-directional drill machine tool which comprises a rack, a clamping mechanism and two drill mechanisms. The two drill mechanisms are installed on the two sides of the rack correspondingly. The clamping mechanism is fixedly installed between the two drill mechanisms. Each drill mechanism comprises a moving device and a drill device, wherein the moving device is movably installed on the rack, and the drill device is installed on the moving device. The clamping mechanism comprises a supporting device, a clamping device and at least two fixing clamps. The clamping device is installed on the supporting device in a rotating manner. The fixing clamps are installed on the clamping device and are distributed uniformly. The practical bi-directional drill machine tool simplifies the drill operation process and improves the drill efficiency.

Owner:芜湖中驰机床制造有限公司

Travel information collection apparatus

InactiveUS8666593B2Way accurateImprove management accuracyInstruments for road network navigationRoad vehicles traffic controlTraffic capacityReal-time computing

Travel information is categorized into plural time slot categories according to information characteristics of traffic flow information that represents a traffic flow of each of road sections in a database of an information center, and a learn database is built for each of the categories derived from above categorization. The travel information collected by a travel of a self vehicle along the road sections is learned according to the categories of the learn database for accurately managing the travel information according to the characteristics of the traffic flow.

Owner:DENSO CORP

Personnel and safety management system

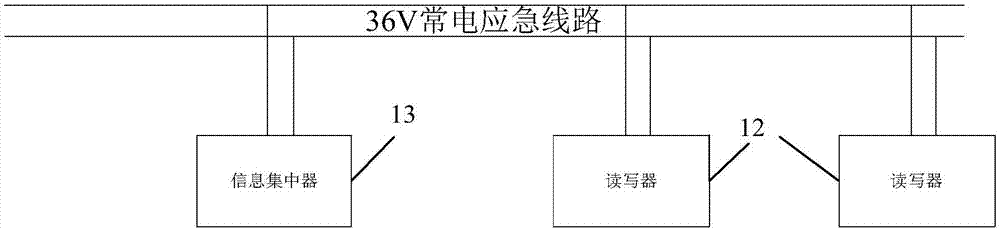

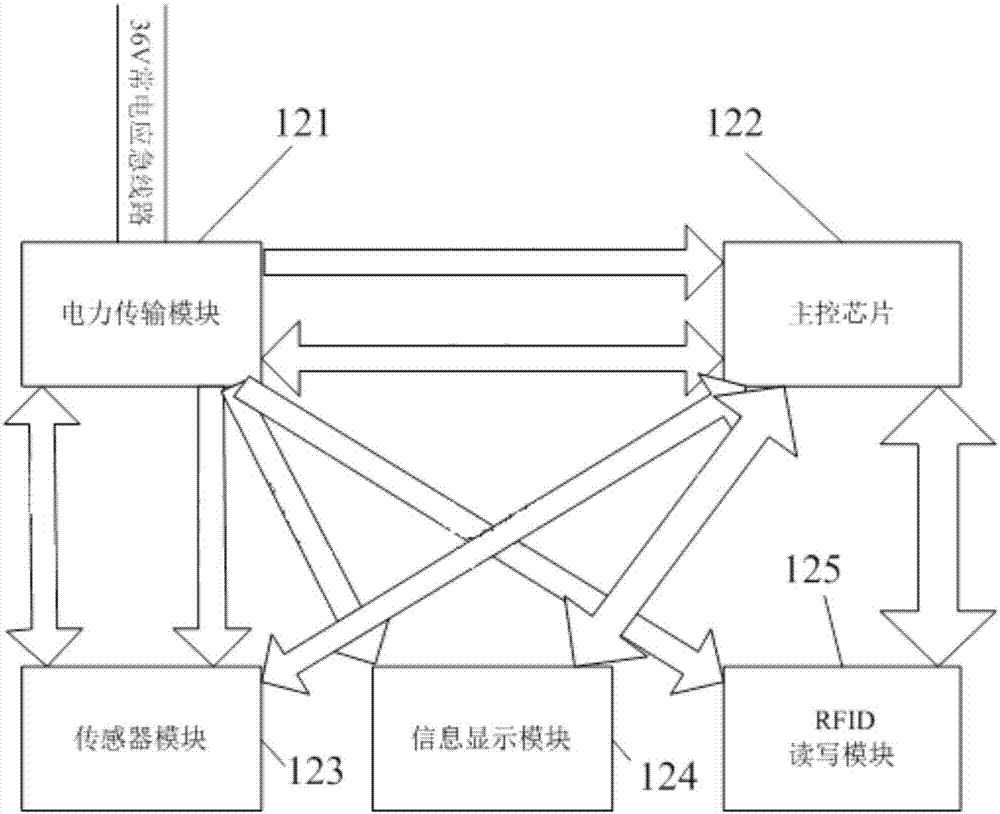

PendingCN107886455AEliminate the wiring processLow costData processing applicationsAutomatic testing and analysing marked record carriersElectric power transmissionSafety management systems

The invention relates to the technical field of safety management, in particular to a personnel and safety management system. The system comprises a field collection unit, a server, a monitoring center and an external data interface, wherein the server is connected with the field collection unit; the monitoring center and the external data interface are connected with the server; and the field collection unit is used for collecting management and safety information of field personnel. A power transmission technology is combined with 2.4G active RFID, 13.56MHz passive RFID and card informationactive transmission technologies, so that the manual wire arrangement and installation costs and a large amount of costs of subsequent wire removal, sorting and the like are reduced, the waste is reduced, and extremely convenient data collection and data active transmission in various shielding and special environments under the condition of not adding any independent data line are realized.

Owner:HAIYANG CIMC RAFFLES OFFSHORE +1

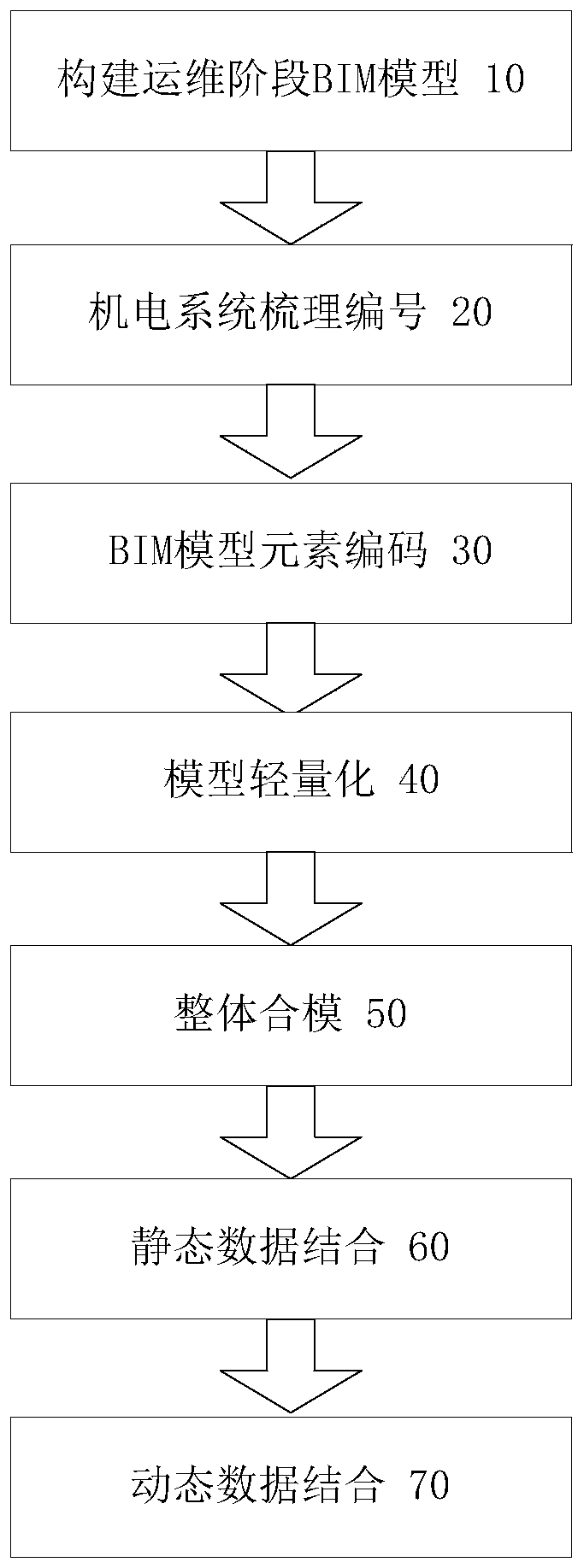

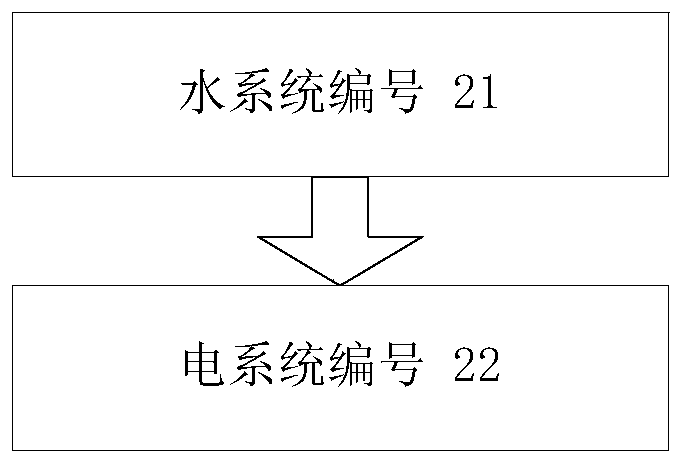

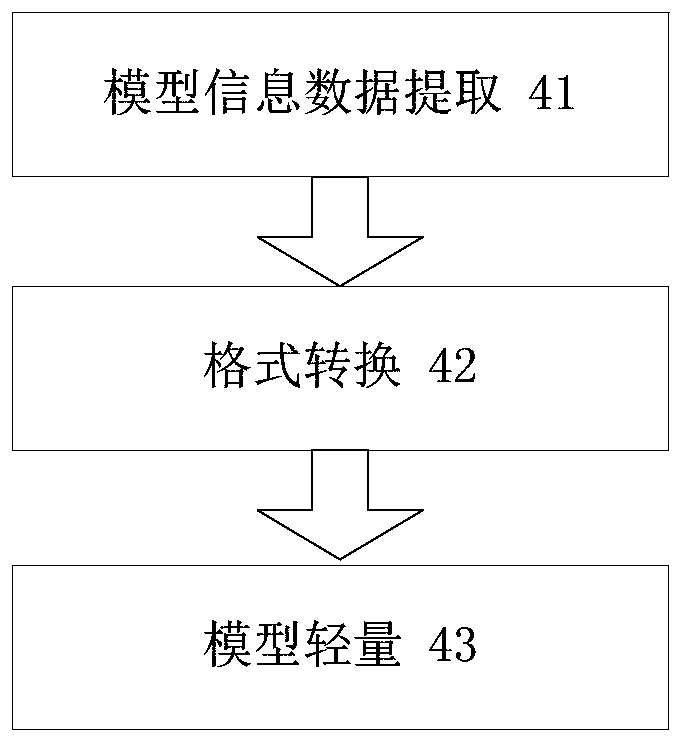

BIM-based electromechanical system upstream and downstream relationship determination method

PendingCN111310256AIntuitive understanding of project system architectureFind quicklyGeometric CADData processing applicationsProcess engineeringDynamic data

The invention discloses a BIM-based electromechanical system upstream and downstream relationship determination method, which is good in information circulation and low in management difficulty. The determination method comprises the following steps: (10) constructing an operation and maintenance stage BIM model: comparing elements in the construction stage BIM model with completion drawings and building sites one by one to form the operation and maintenance stage BIM model; (20) sorting and numbering an electromechanical system: numbering electromechanical pipelines and equipment according tothe system; (30) BIM model element coding: constructing and coding different electromechanical elements; (40) model light weight: realizing model light weight through the constructed surface reduction and format conversion; (50) overall mold closing: establishing a model system tree, and carrying out overall mold closing on the building pipelines according to the system type; (60) static data combination: combining static information required in an operation and maintenance stage into BIM construction; and (70) dynamic data combination: binding the real-time state measurement points to the construction.

Owner:南京戎光软件科技有限公司

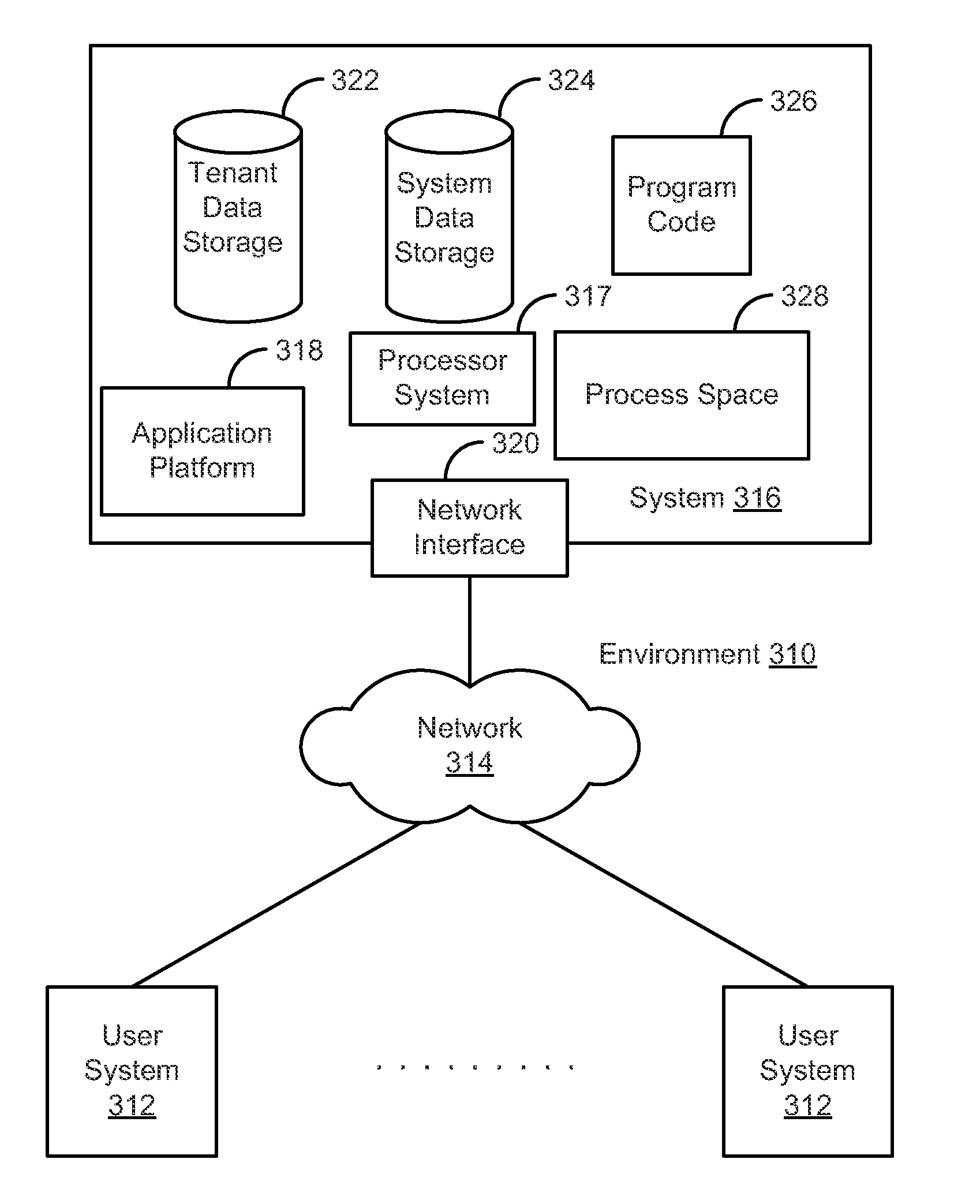

System, method and computer program product for managing access to systems, products, and data based on information associated with a physical location of a user

ActiveUS9246892B2Easy data managementImprove management accuracyTransmissionProgram/content distribution protectionData managementManagement efficiency

In accordance with embodiments, there are provided mechanisms and methods for managing access to data based on information associated with a physical location of a user. These mechanisms and methods for managing access to systems, products, or data based on information associated with a physical location of a user can enable improved data management efficiency, enhanced data management accuracy, decreased data management costs, decreased licensing costs, increased security, additional marketing opportunities, etc.

Owner:SALESFORCE COM INC

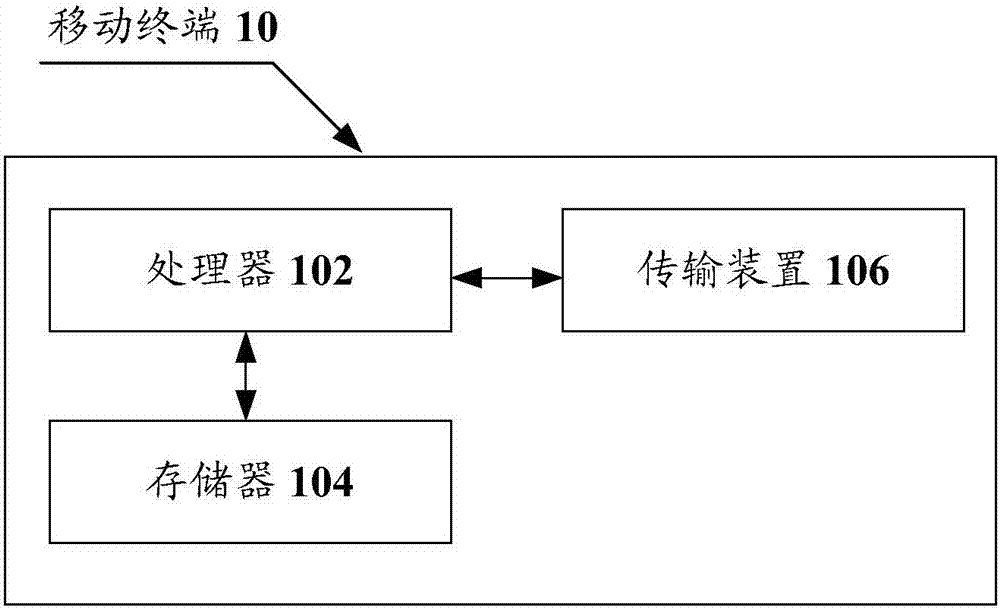

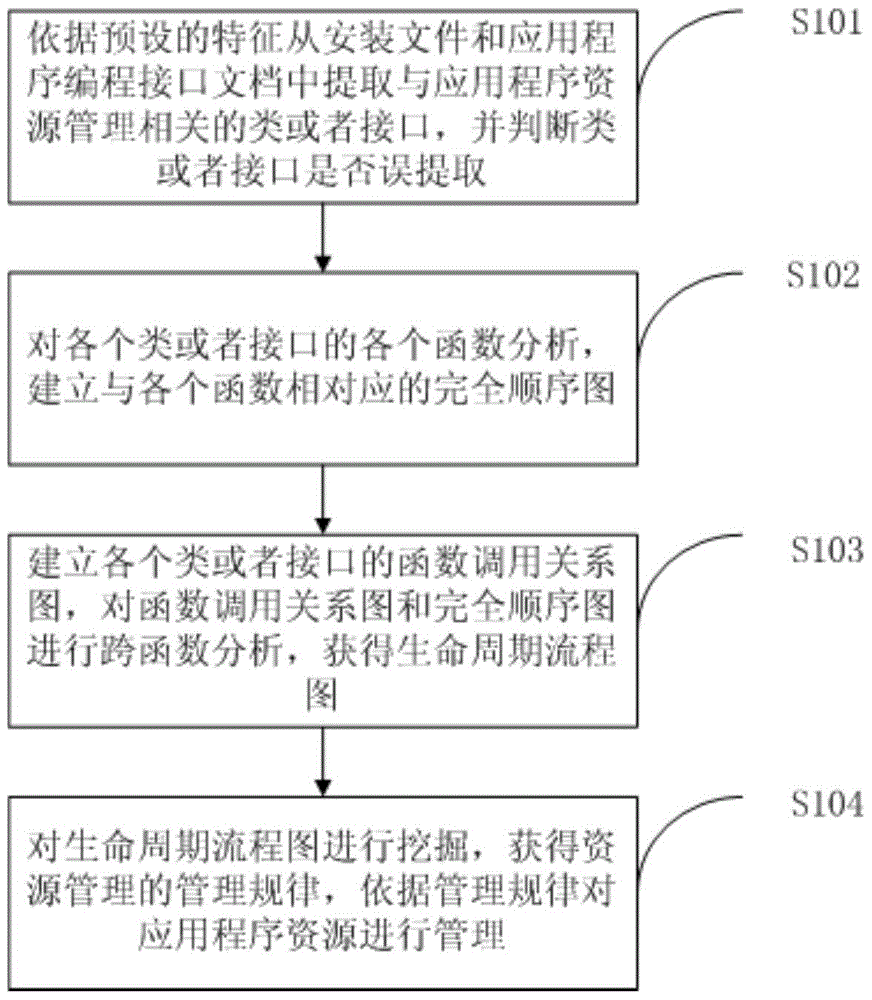

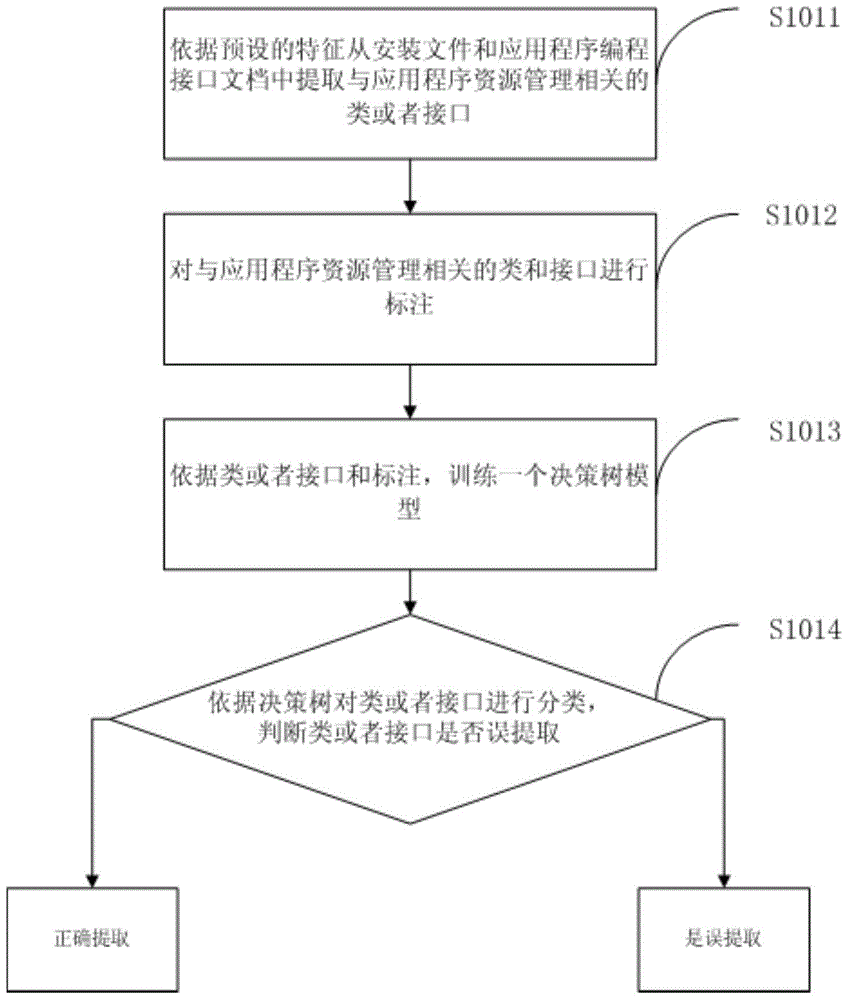

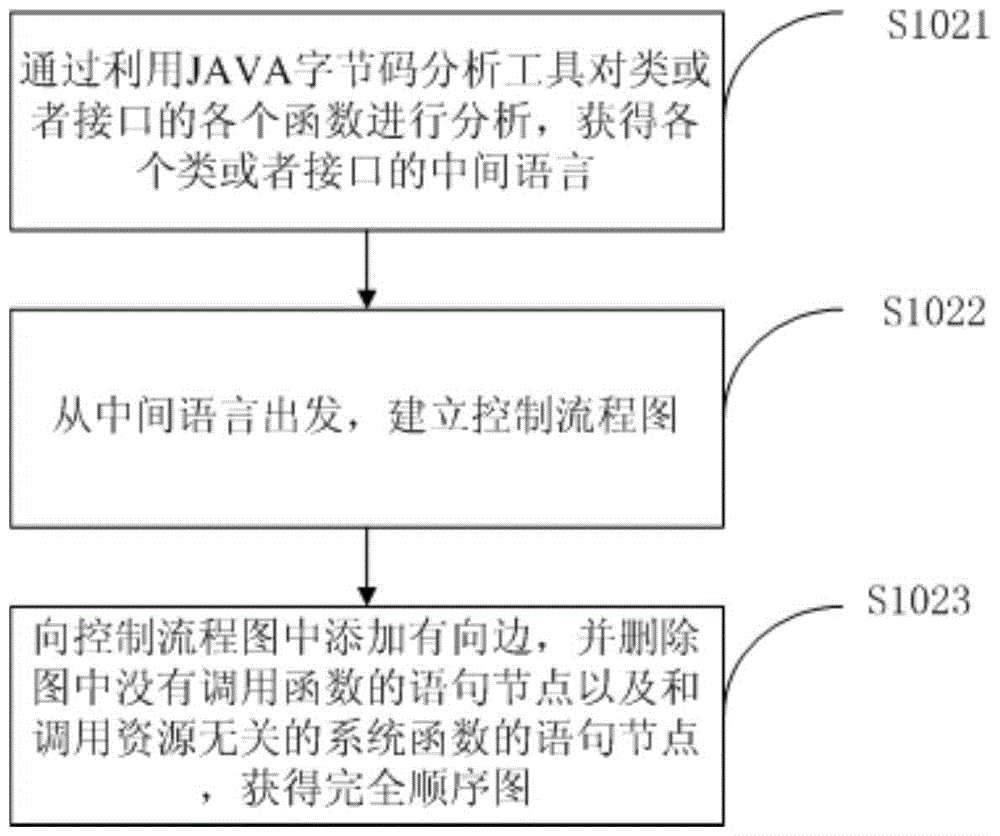

A method for managing resources of a mobile terminal

ActiveCN103559094BImprove management accuracyResource allocationApplication programming interfaceSoftware engineering

The invention discloses a method for managing resources of a mobile terminal. The method comprises the following steps: extracting types or interfaces related to application program resources from an installation document and an application program programmatic interface document according to the preset features and judging whether the types or the interfaces are extracted by mistake; analyzing all functions of the types or the interfaces, and establishing complete sequence diagrams corresponding to the functions; establishing function call relation diagrams of the types or the interfaces, and performing cross-function analysis on the function call relation diagrams and the complete sequence diagrams to obtain a life-cycle flow diagram; mining the life-cycle flow diagram to obtain resource management rules. By adopting the method disclosed by the invention, application programs can be analyzed and mined to obtain the resource management rules, the application program resources are managed according to the management rules, and accordingly, the accuracy in managing various resources on an intelligent mobile terminal platform is improved.

Owner:RUN TECH CO LTD

Storage object management for cold storage plant, and cold storage plant

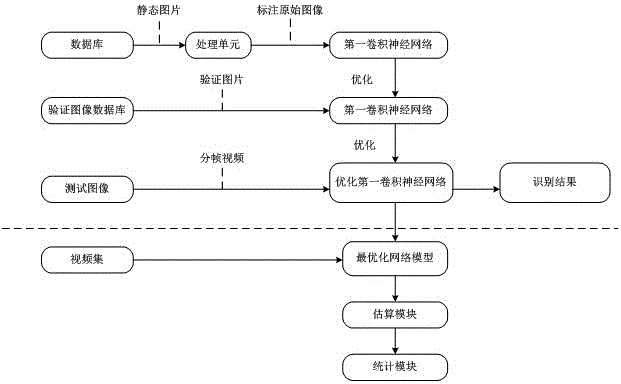

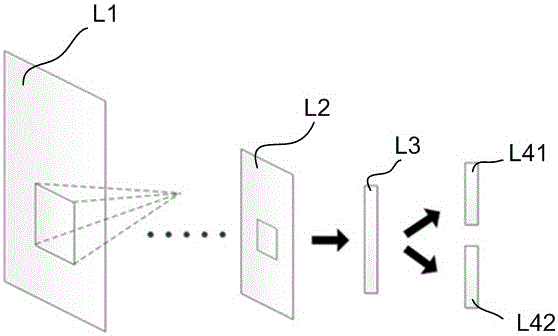

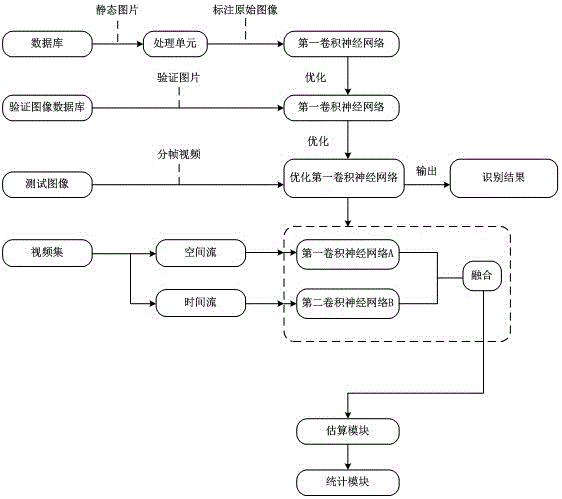

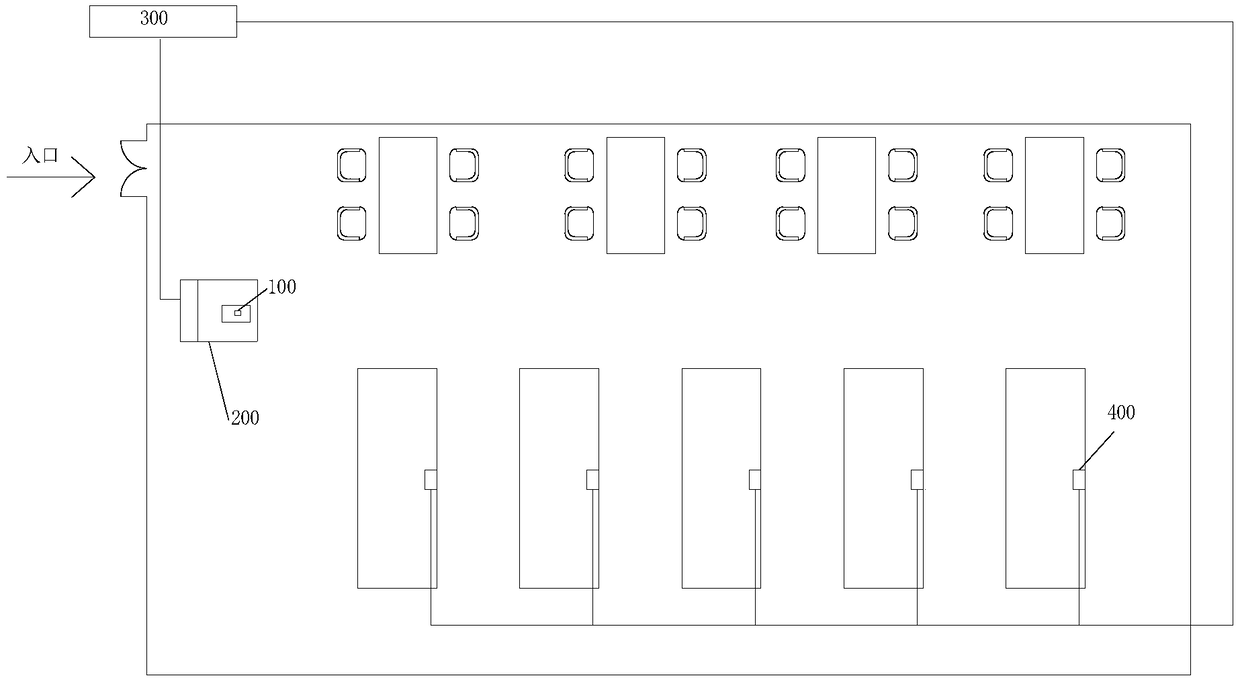

ActiveCN107527060AImprove management accuracyStatistics are accurateImage enhancementImage analysisManagement systemConvolution

The invention provides a storage object management for a cold storage plant, and the cold storage plant. The system comprises a training module based on a convolution neural network, wherein the training module is used for learning and detecting target storage objects; a recognition module based on a convolution neural network, wherein the recognition module is used for recognizing whether there are the target storage objects or not and the types of the target storage objects; a detection module based on a convolution neural network, wherein the detection module is used for the capturing detection of whether there are the target storage objects and whether the target storage objects are stored in the cold storage plant or are taken out of the cold storage plant. The system can build the convolution neural network through the training, verification and testing steps, so as to achieve the automatic learning, interaction, recognition and counting of the target storage objects in the cold storage plant, the types of the target storage objects and the changes of the number of each type of target storage objects according to a sampling video. The using mode of a conventional cold storage plant does not need to be changed. The system achieves the intelligent and automatic counting and interaction functions, is high in management precision, is accurate in statistic data, and is good in use flexibility.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

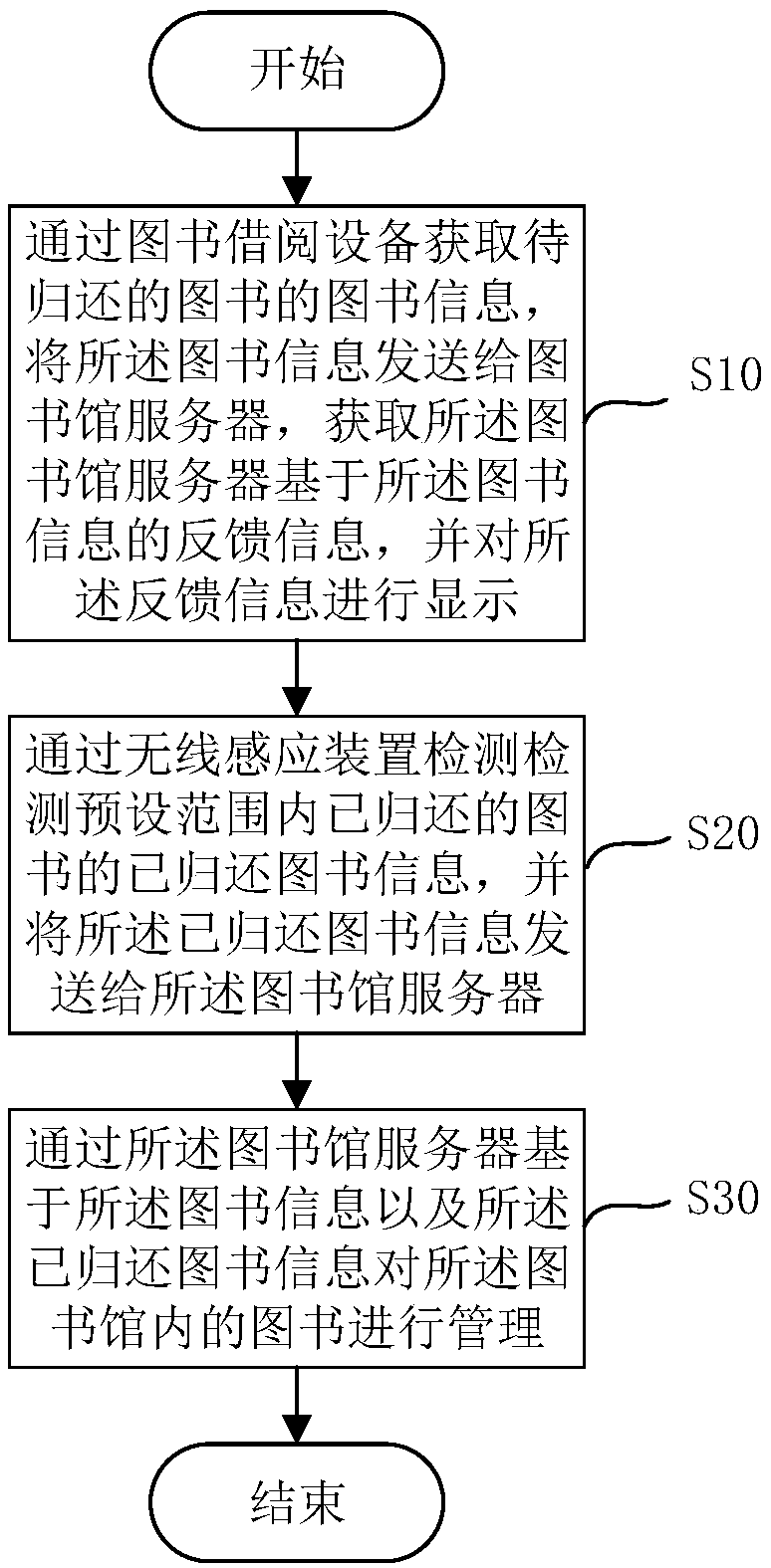

Management system and management method of books in a library

InactiveCN109034299AReduce workloadImprove work efficiencyCo-operative working arrangementsElectricityLibrary services

The invention discloses a management method of books in a library. The system comprises wireless induction tags, which are one-to-one correspondingly arranged in books and used for storing book information; a book borrowing device, set up in a library, the book borrowing device comprising a book sensing device and a display device, which are used for sensing the wireless sensing tags to obtain book information through the book sensing device, sending the book information to the library server, obtaining the feedback information based on the book information of the library server and displayingthe feedback information through the display device; a wireless sensing device arranged on a book shelf and used for detecting returned book information of returned books within a preset range and sending the returned book information to a library server; the library server which is electrically connected with the wireless sensing device and a book borrowing device, and is used for managing bookin the library based on the book information and the returned book information. The invention also discloses a management method of books in a library.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

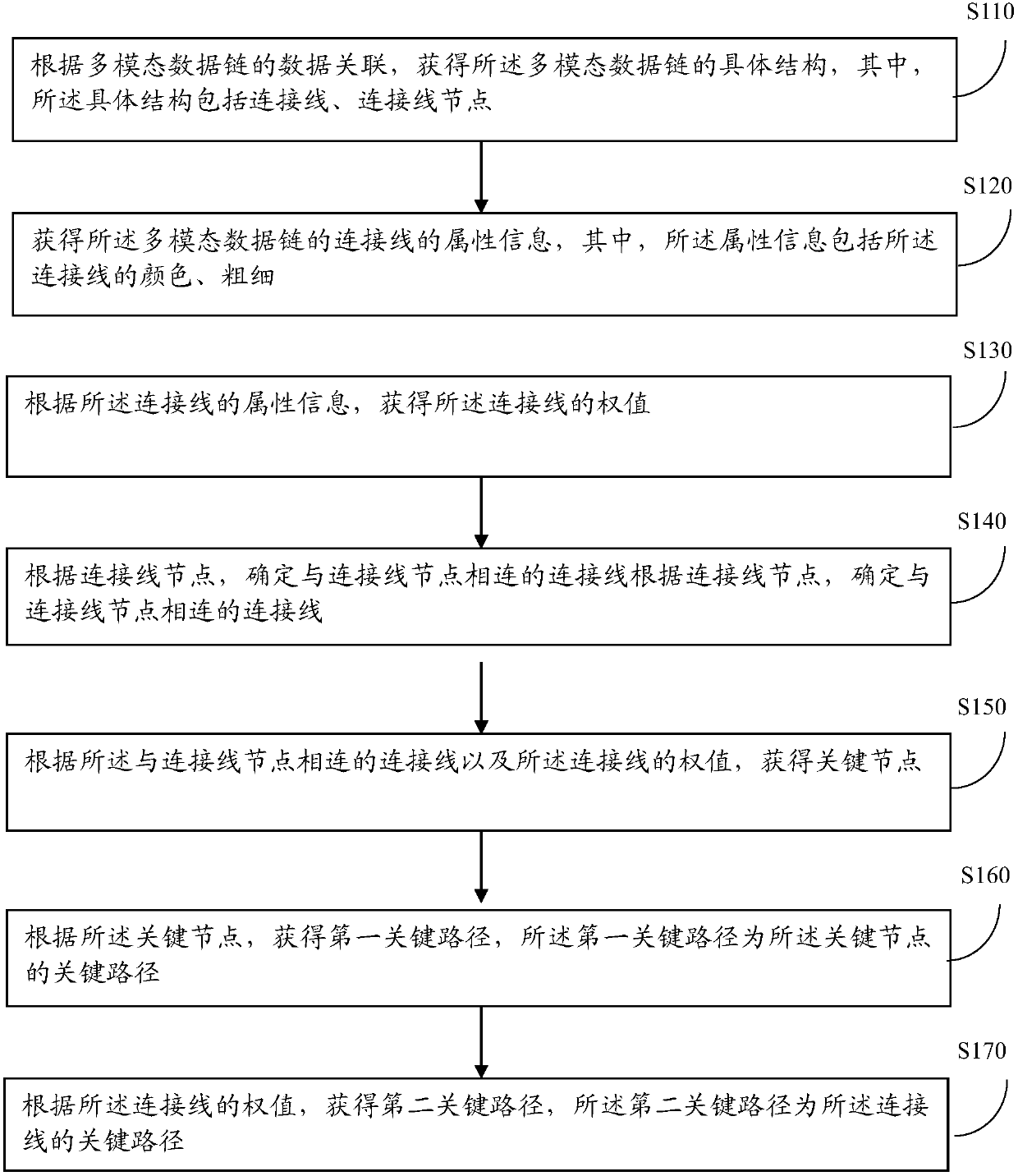

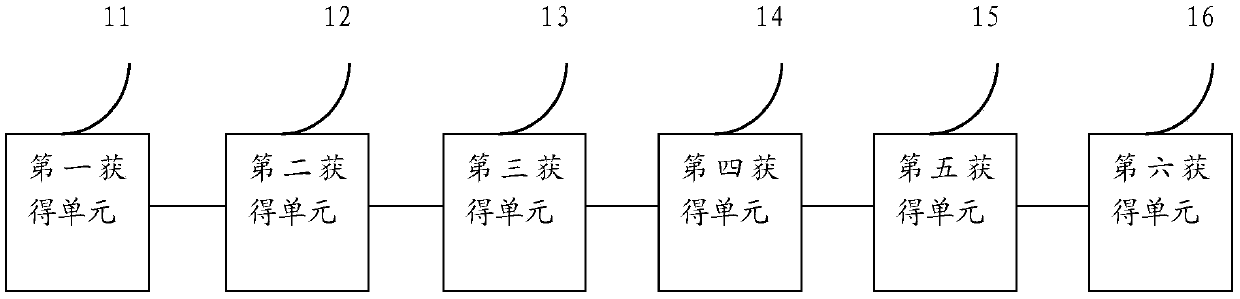

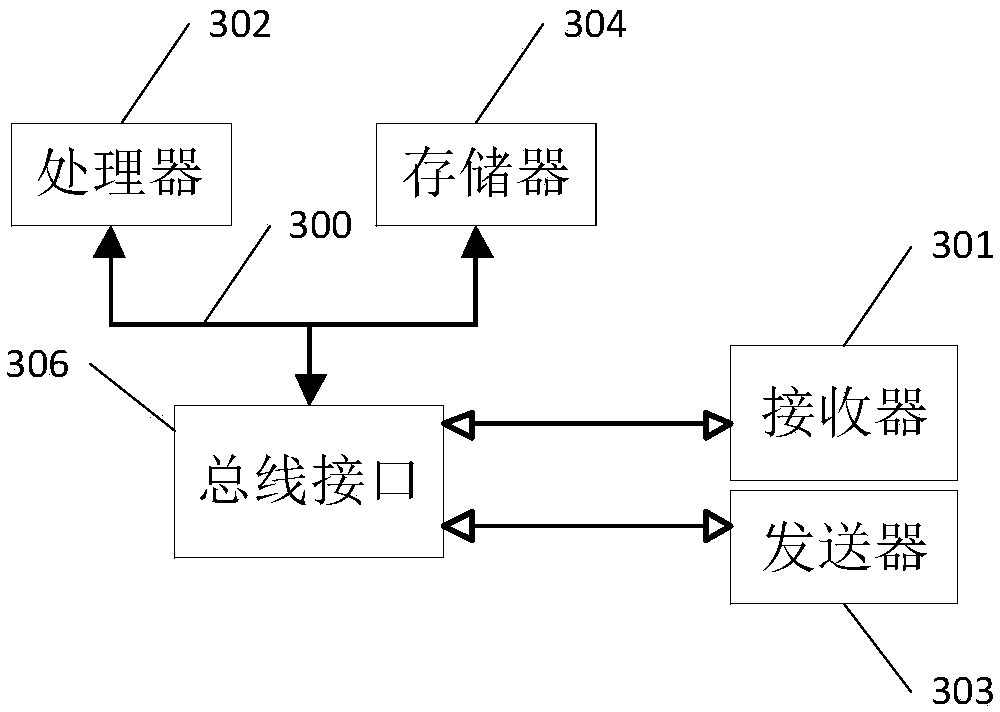

Data analysis method and device

ActiveCN107729478AEfficient managementEfficient use ofVisual data miningStructured data browsingInformation processingCritical path method

The invention provides a data analysis method and device, and relates to the technical field of information processing. The data analysis method comprises the steps of obtaining a specific structure of a multimoding data chain according to data association of the multimoding data chain, wherein the specific structure comprises a connecting line and a connecting line node; obtaining attribute information of the connecting line of the multimoding data chain; obtaining a weight of the connecting line according to the specific structure of the multimoding data chain and the attribute information of the connecting line; obtaining key nodes according to the weight of the connecting line; obtaining a first key path according to the key nodes, wherein the first key path is the key path of the keynodes; obtaining a second key path according to the weight of the connecting line, wherein the second key path is the key path of the connecting line. The technical problem in the prior art that in anorganization process of case materials, the efficiency is low, and cooperative case handling by many people is inconvenient is solved.

Owner:天津微迪加科技有限公司

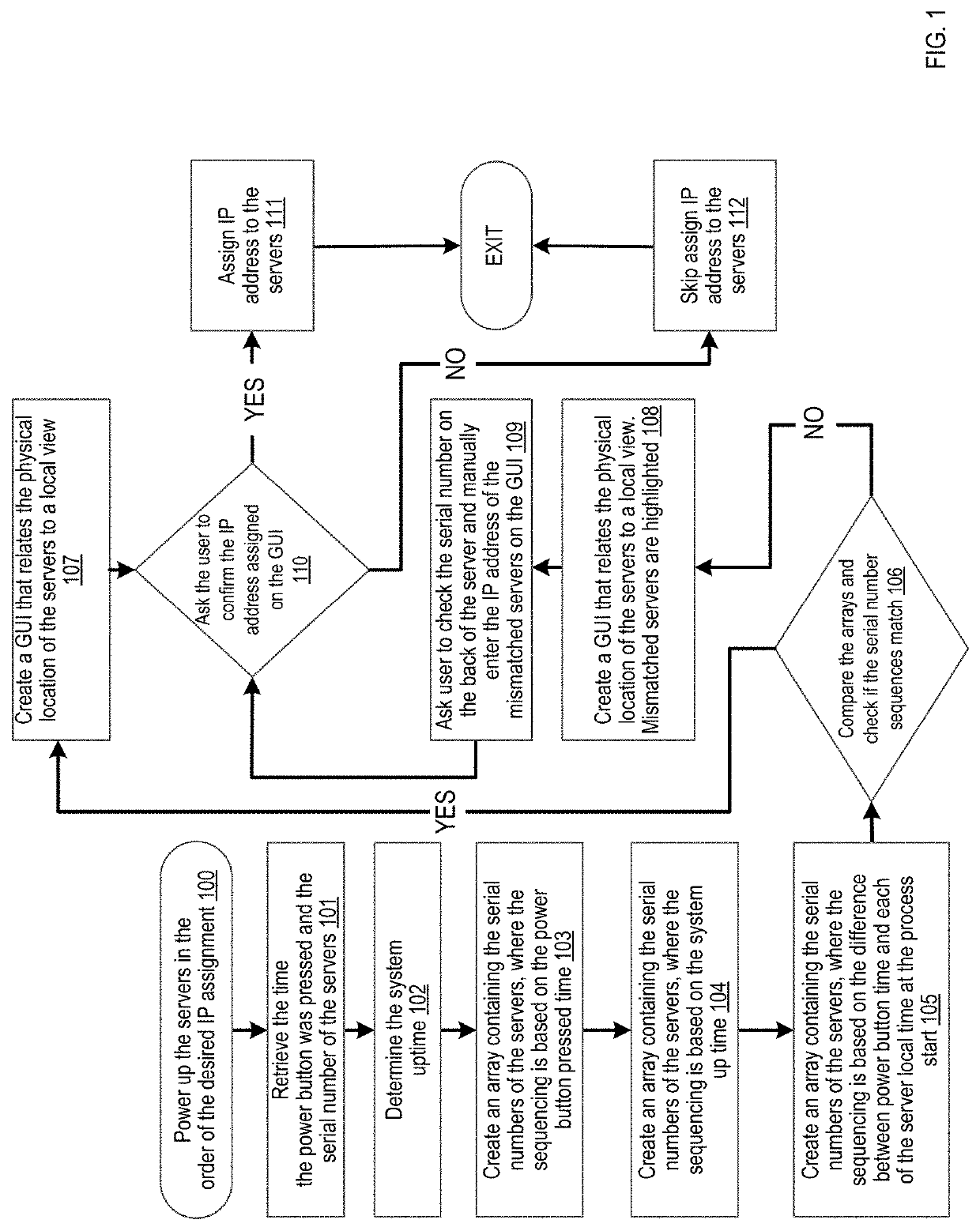

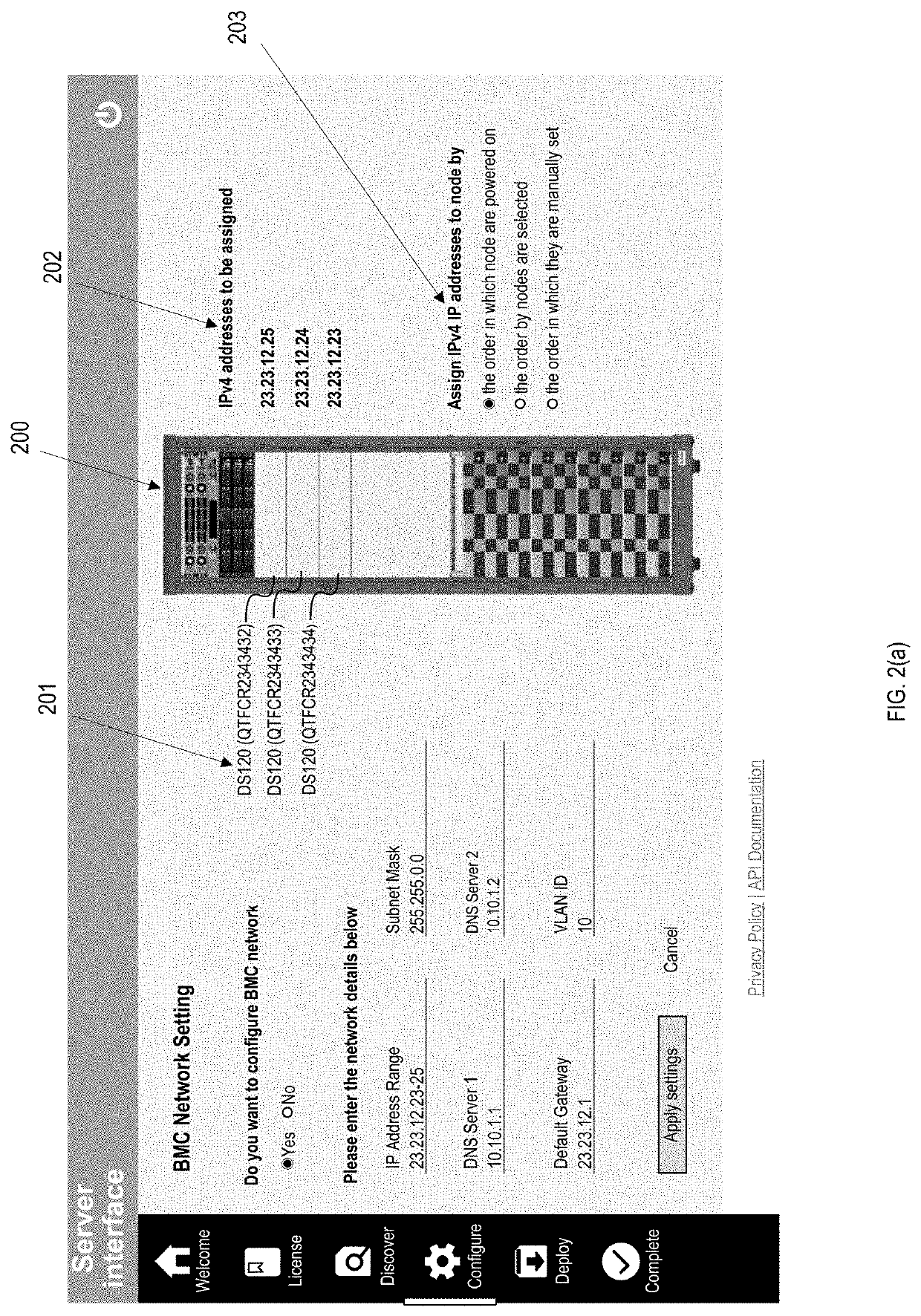

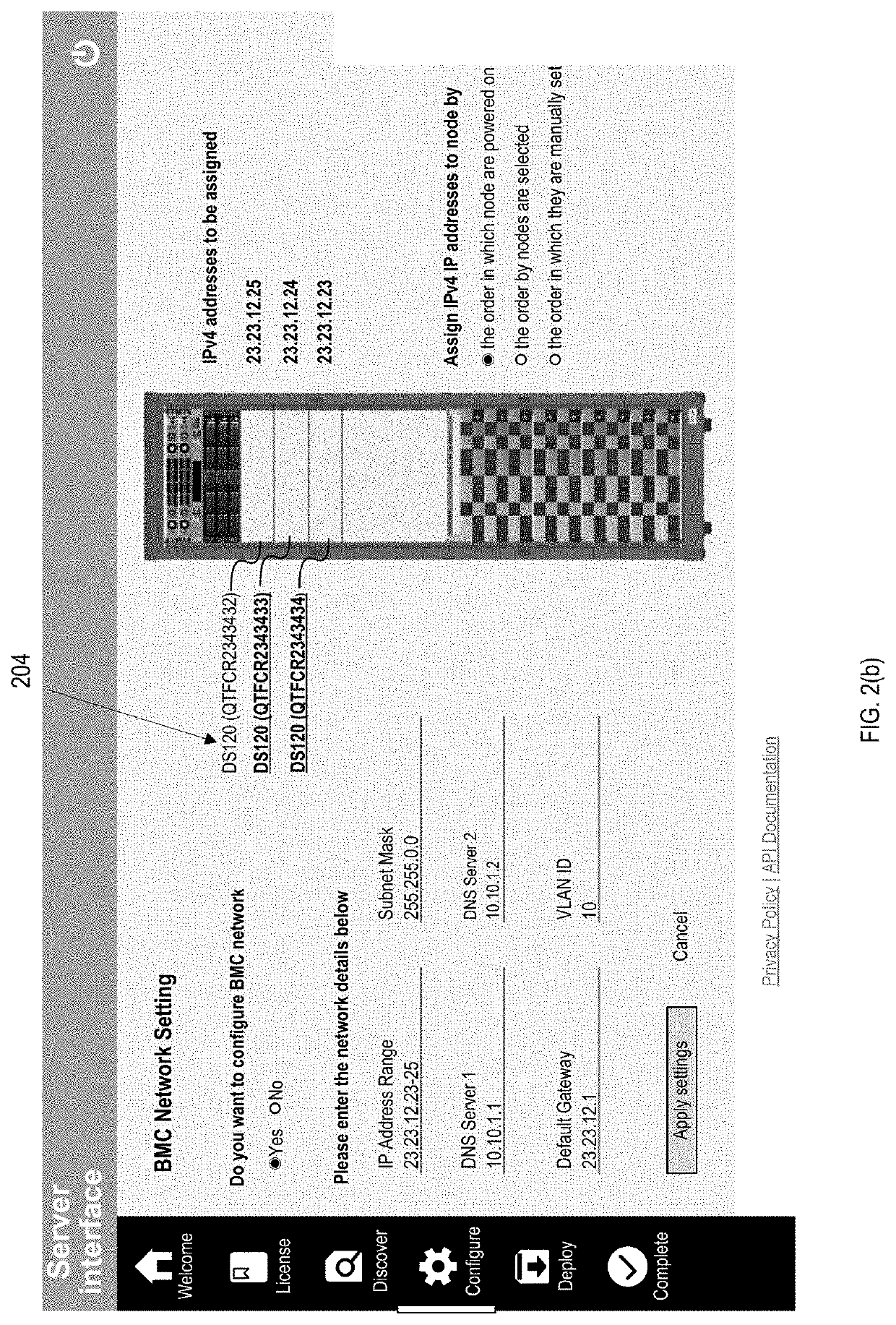

Systems and methods for identifying servers on a rack and assigning the proper IP addresses to the servers based on their physical locations

ActiveUS20220210115A1Improve management accuracyReduce deployment timeTransmissionOperational systemIp address

Example implementations described herein are directed to systems and methods for managing internet protocol (IP) address assignment to servers on rack(s) based on their physical locations within the rack(s). Through the example implementations, the physical location of a server within a data center rack can be determined based on the IP address. Example implementations can involve issuing a ping local to determine a plurality of servers; retrieving power on time, current system time, and operating system (OS) uptime for each of the plurality of servers; determining a power on order for the plurality of servers; determining physical locations of the plurality of servers within one or more racks based on installation instructions and power on order; and assigning IP addresses to the plurality of servers based on the physical locations.

Owner:HITACHI VANTARA LLC

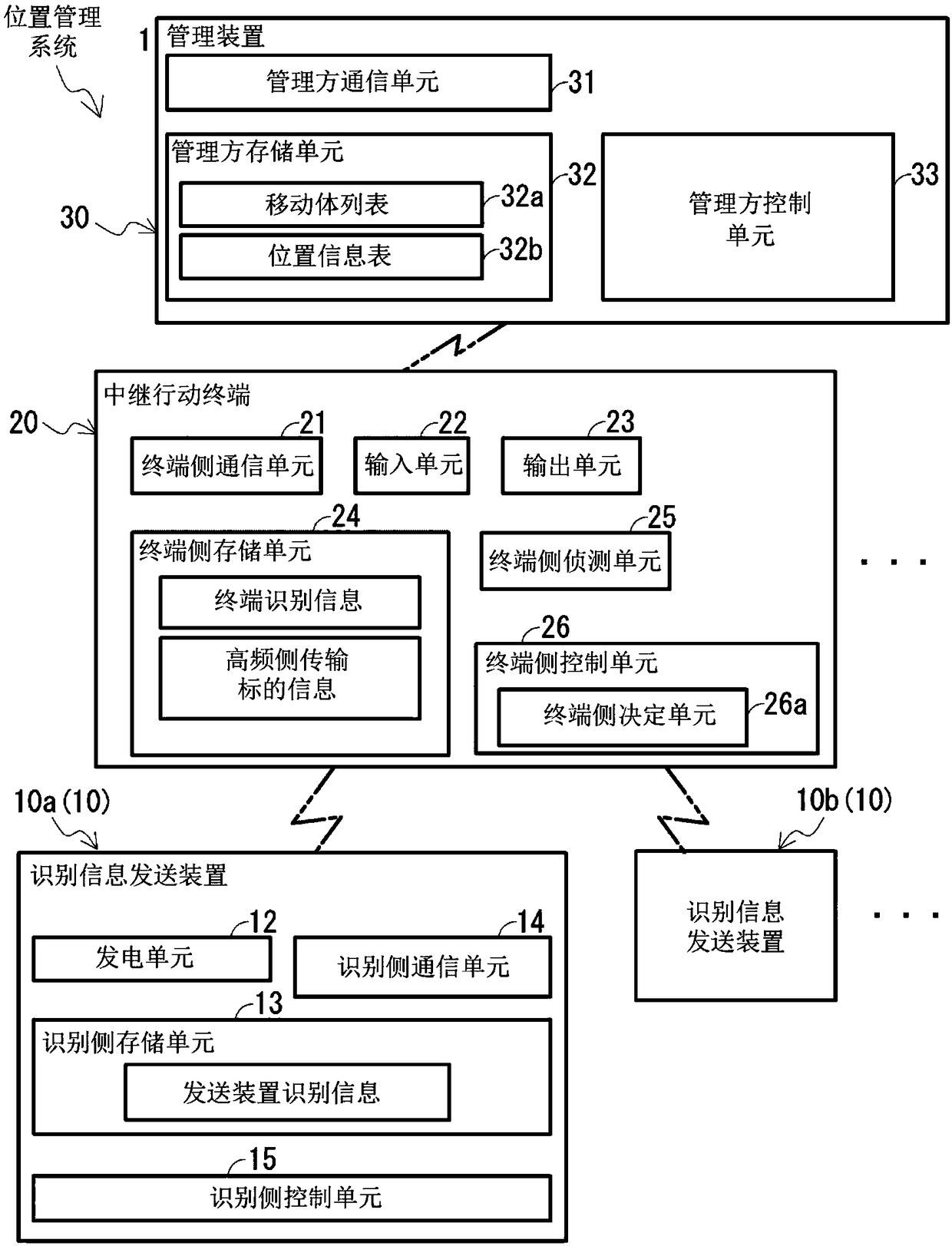

Control system

InactiveCN109417679AUnlimited capacityContinuous and stable controlPosition fixationTelephonic communicationCommunication unitControl system

A position management system 1 provided with an identification information transmitter 10, a relaying mobile terminal 20, and a management device 30, wherein the identification information transmitter10 is provided with: a power generation unit 12 that is held by a moving person and that generates electric power using environmental energy; an identification-side storage unit 13 for storing transmitter identification information that is intended for uniquely identifying the identification information transmitter 10; and an identification-side transmission unit 14 which, by using the electric power generated by the power generation unit 12 when a transmission condition is met, wirelessly transmits an identification-side signal that includes the transmitter identification information storedby the identification-side storage unit 13. The relaying mobile terminal 20 is provided with a terminal-side communication unit 21 for receiving the identification-side signal transmitted from the identification information transmitter 10, and a terminal-side communication unit 21 for wirelessly transmitting a relaying-side signal. The management device 30 is provided with a management-side communication unit 31 for receiving the relaying-side signal transmitted from the relaying mobile terminal 20, and a management-side control unit 33 for performing control on the basis of the relaying-sidesignal received by the management-side communication unit 31.

Owner:SOUNDPOWER CORP

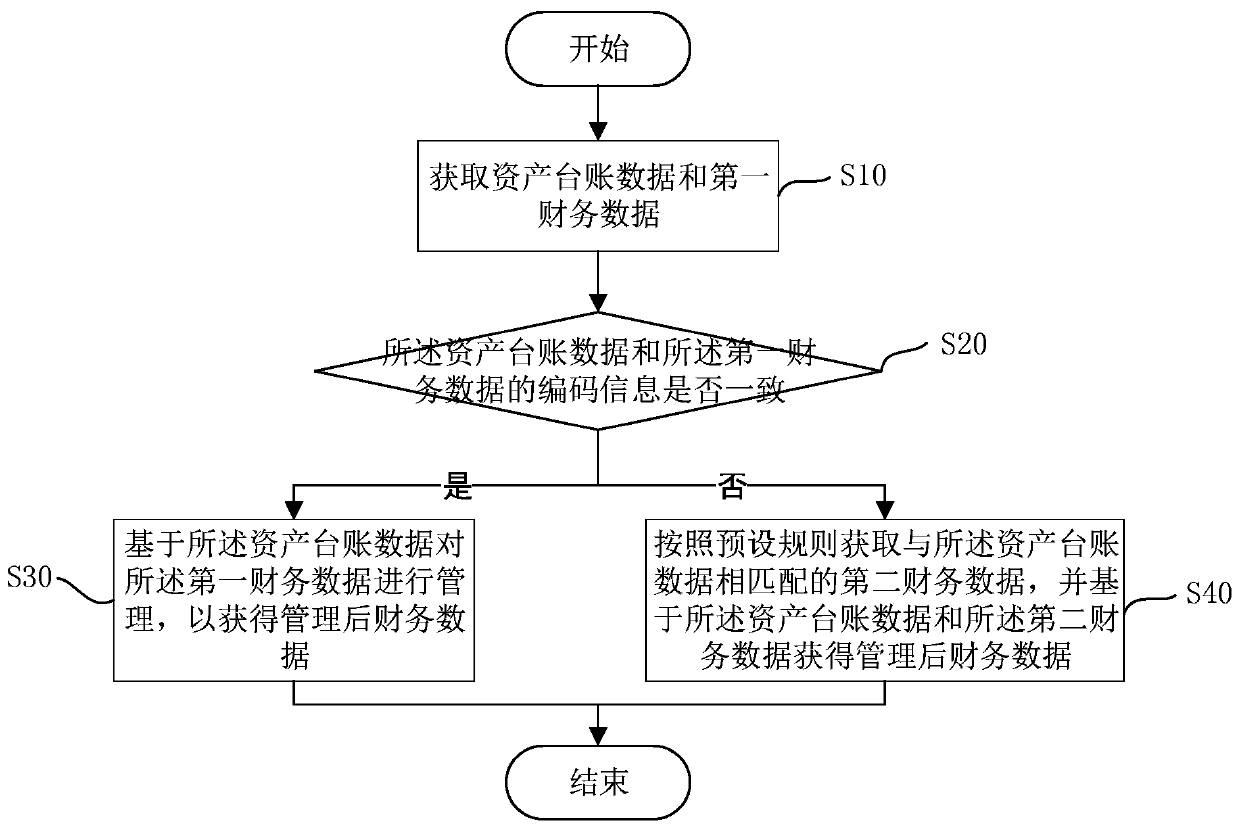

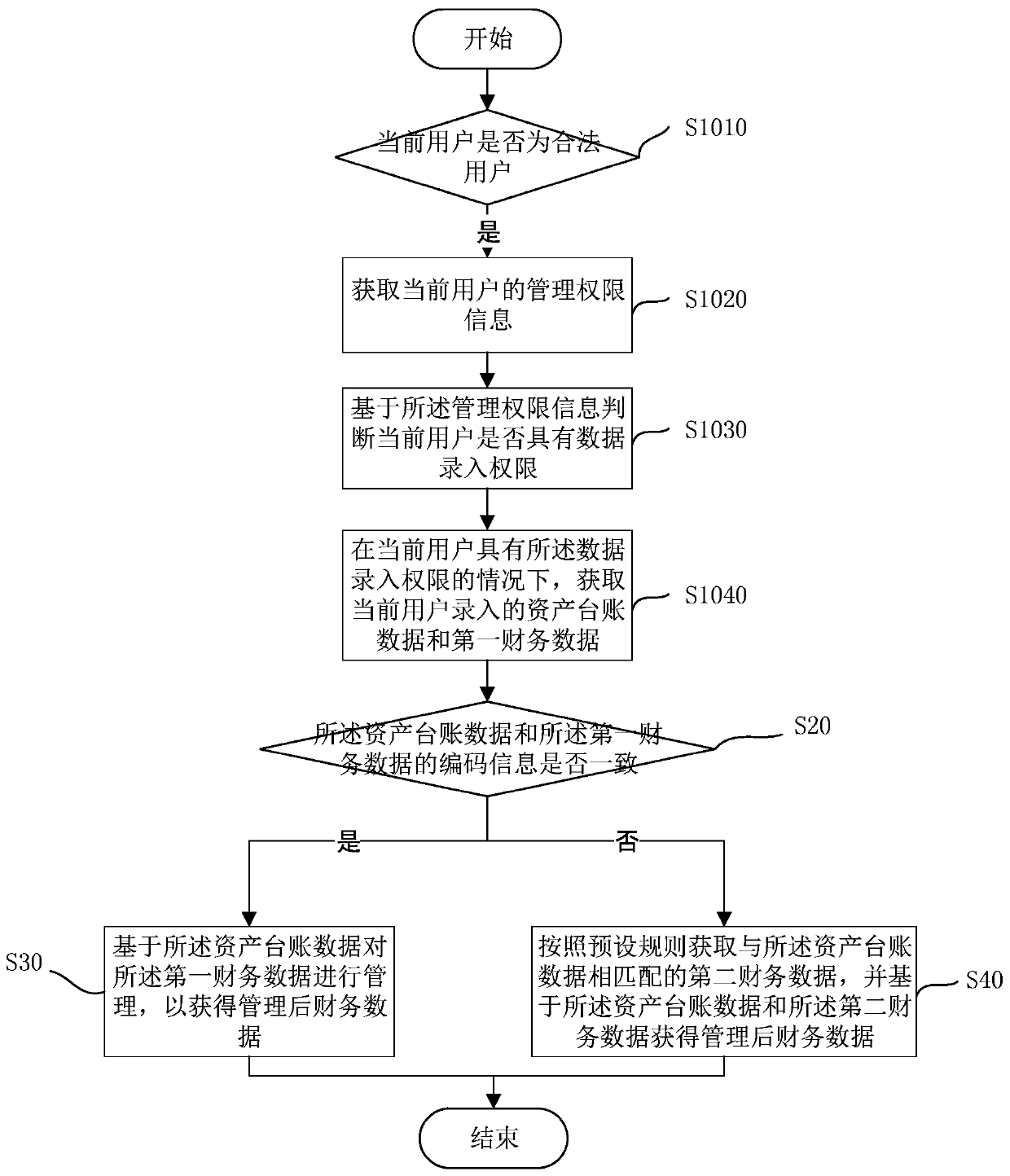

Management method for financial data of power supply bureau

PendingCN110442566AImprove management efficiencyImprove management accuracyDigital data information retrievalFinanceManagement efficiencyData mining

The invention discloses a management method for financial data of a power supply bureau. The management method comprises the steps of obtaining asset standing book data and first financial data; judging whether the coded information of the asset standing book data is consistent with the coded information of the first financial data or not; if so, managing the first financial data based on the asset standing book data to obtain managed financial data; otherwise, obtaining second financial data matched with the asset standing book data according to a preset rule, and obtaining managed financialdata based on the asset standing book data and the second financial data. On the basis of an existing power supply asset and financial management system, an automatic matching and automatic managementmethod for financial data is established, and technicians can automatically analyze and manage asset standing book data and financial data, so that on one hand, a large amount of repeated calculationof the technicians is reduced, the management efficiency is improved, on the other hand, the influence of human factors is avoided, and the management accuracy is improved.

Owner:GUIZHOU POWER GRID CO LTD

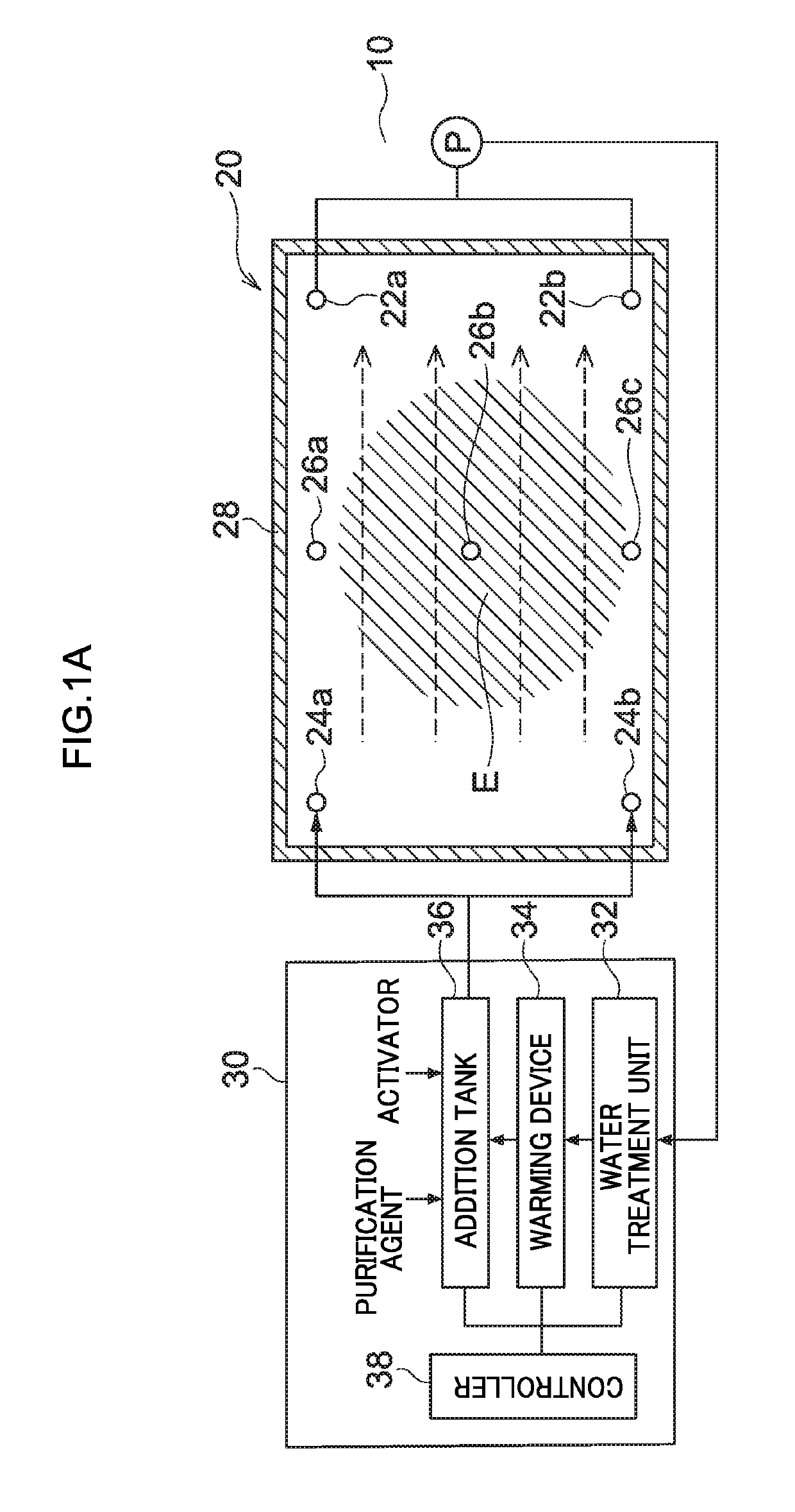

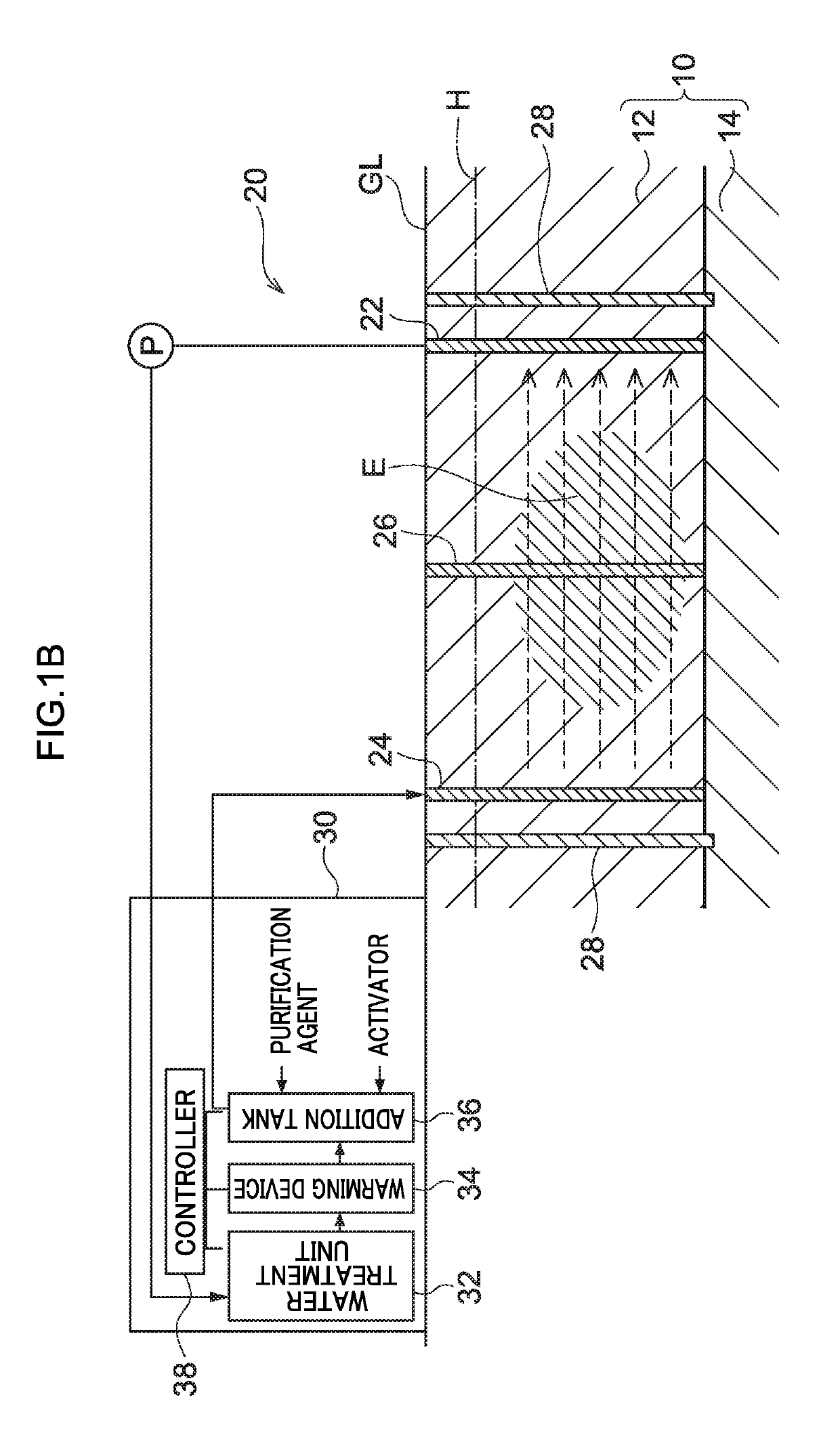

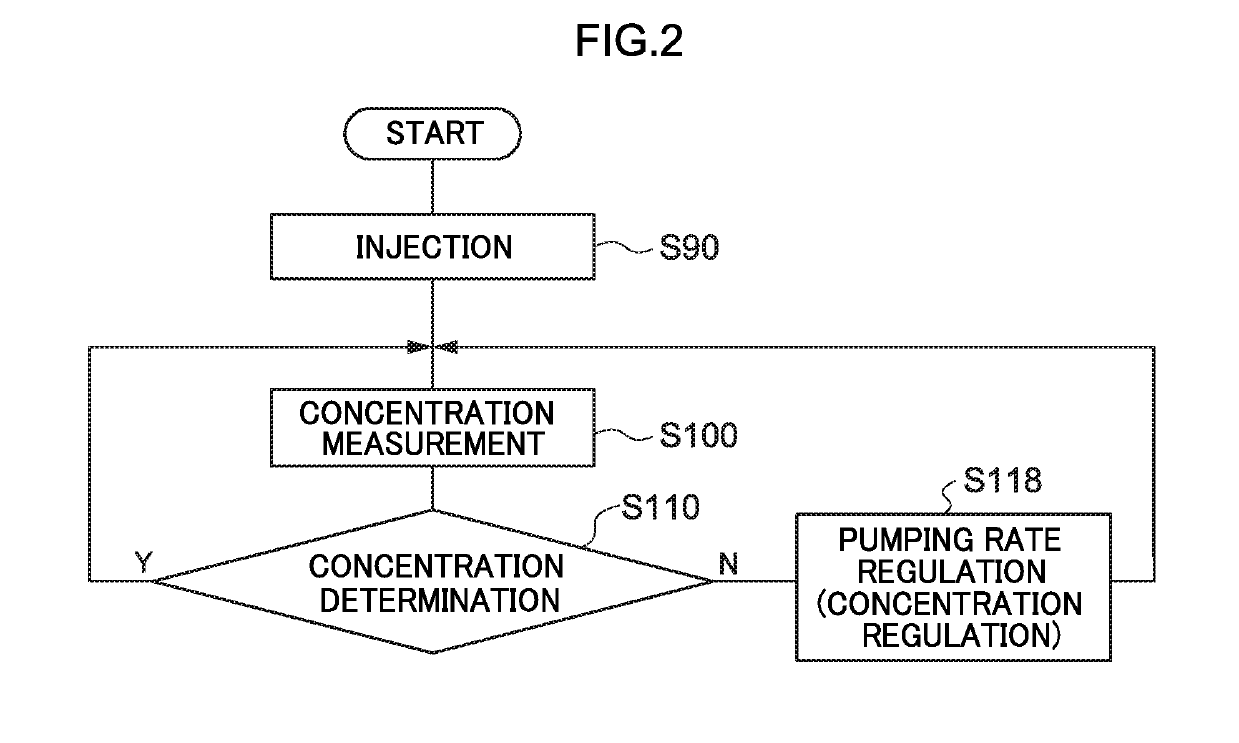

Contaminated soil purification method

ActiveUS20190232347A1Improve management accuracyImprove forecast accuracyContaminated soil reclamationFluid removalAutomatic controlPurification methods

A contaminated soil purification system for decomposing a contaminant in contaminated soil E. The contaminated soil purification system includes: injecting, into contaminated soil through a water injection well, an injection liquid containing a purification agent to decompose a contaminant or an activator to stimulate biological decomposition by the purification agent; a process of measuring a concentration of the purification agent or the activator in groundwater in an observation well or in a pumping well, the observation well or the pumping well being provided at a location spaced apart from the water injection well; and a process of, based on the concentration that has been measured, automatically controlling an addition amount of the purification agent or the activator to the injection liquid or automatically controlling a pumping amount of water from the pumping well.

Owner:TAKENAKA KOMUTEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com