Bent tube machining tool high in automation degree

A technology for processing machine tools and pipe bending, which is applied in the field of pipe bending processing machine tools, can solve the problems of low efficiency in straightening and cutting long pipes, affecting the progress of production or construction work, and inability to straighten and cut long pipes, etc., to achieve the degree of machine automation High efficiency, convenient production work, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

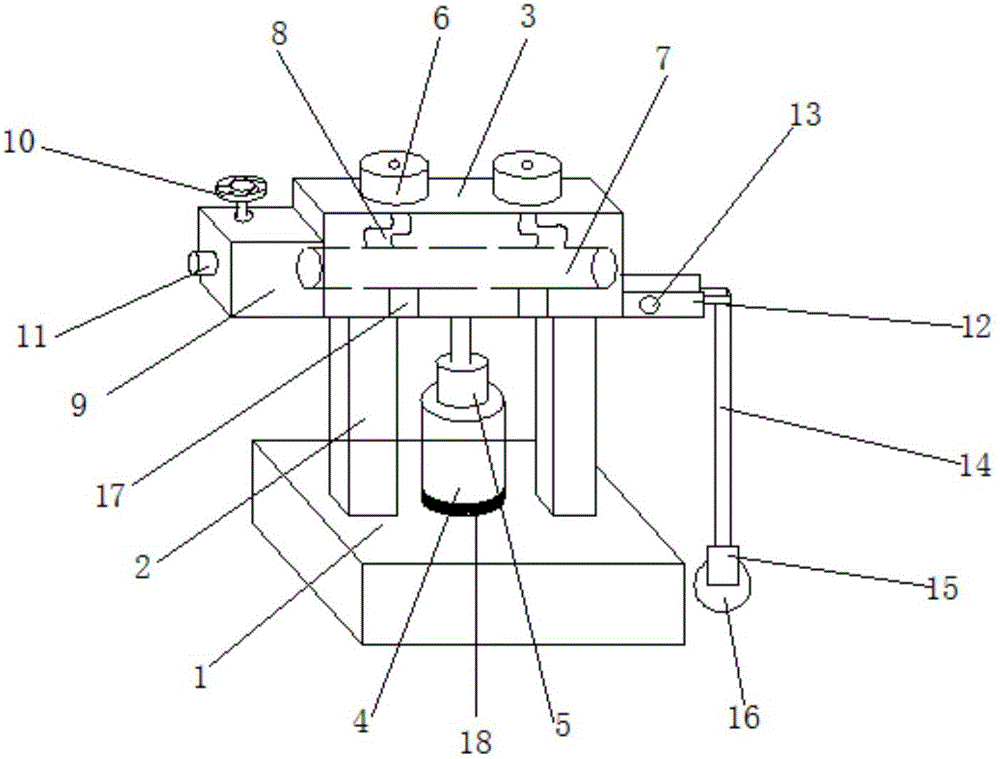

[0010] see figure 1 , the utility model is a pipe bending processing machine tool with a high degree of automation, including a base 1, a support column 2, a linkage straightening cabin 3, an engine 4, a rotating speed cylinder 5, a traction device 6, a straightening cylinder 7, and a force-applying wire rope 8 , cut-off box 9, rotary valve 10, place pipe 11, telescopic device 12, start key 13, mobile table leg 14, fixed frame 15, driving roller 16, damping plate 17 and fixed draw-in groove 18. in,

[0011] The upper side of the base 1 is provided with a support column 2, and the upper side of the support column 2 is provided with a linkage straightening cabin 3, the engine 4 is connected with the linkage straightening cabin 3 through the rotating speed drum 5, and the traction device 6 is arranged on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com