Three-dimensional vision accurate guiding and positioning method for automobile intelligent manufacturing automatic feeding

A technology of intelligent manufacturing and automatic feeding, applied in the direction of manufacturing tools, program control manipulators, manipulators, etc., can solve the problems of high installation and maintenance costs, failures, etc., and achieve high installation and maintenance costs, high grasping accuracy, and convenience The effect of post-maintenance and adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

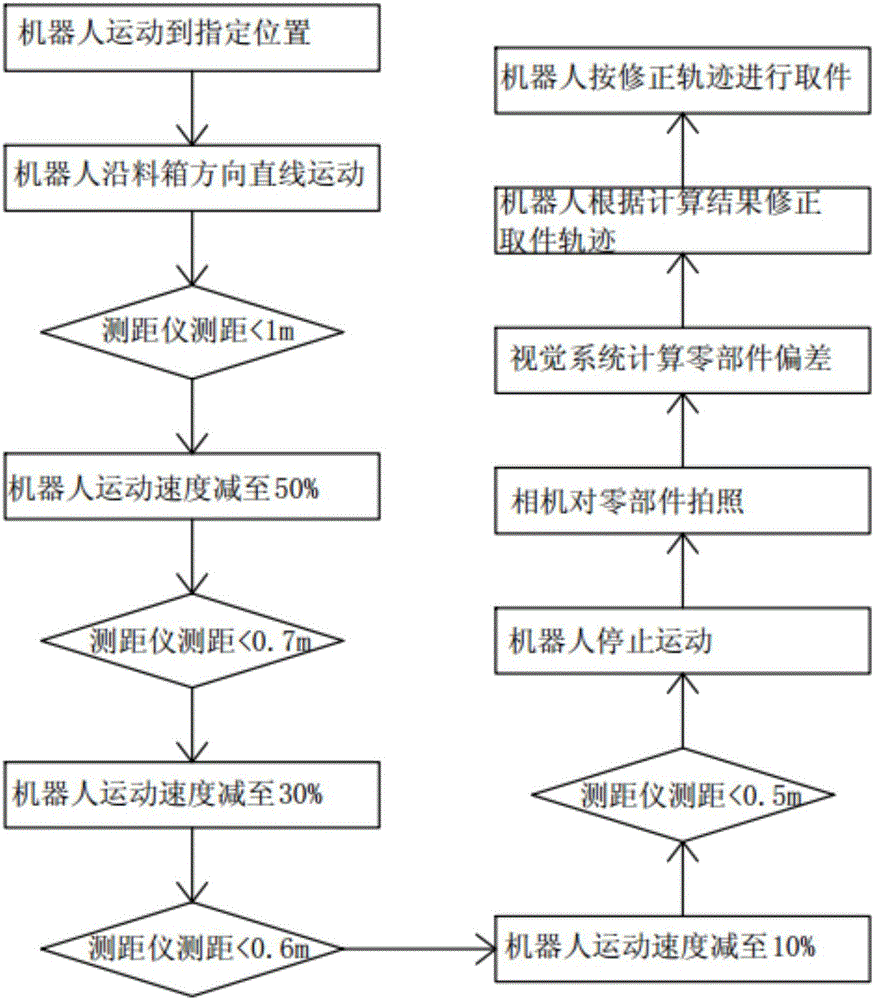

[0028] The embodiment of the present invention discloses a three-dimensional vision precise guidance and positioning method for automatic loading of automobile intelligent manufacturing. The visual detection algorithm calculates the position and angle deviation of the part in the fixed coordinate system, so that the robot can automatically correct the track and grab the material.

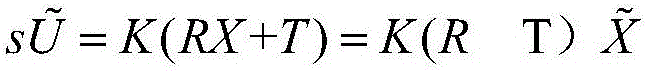

[0029] The visual detection algorithm, the visual detection algorithm is to solve the position and attitude of the object relative to the camera at the time of shooting through the n image points obtained by perspective projection. Remember the camera coordinate system O c -x c the y c z c The orientation of the object coordinate system O-xyz is [R,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com