Traditional Chinese medicine fine powder compression mold forming technique

A technology of compression molding and traditional Chinese medicine, which is applied in the field of traditional Chinese medicine, can solve the problems of limited application fields, unattractive appearance, and high brittleness, and achieve the effect of simple process conditions, easy operation, and increased coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Described traditional Chinese medicine fine powder compression molding process comprises the steps:

[0042] (1) Chinese medicine pretreatment; Chinese medicine fine powder with a particle size of 60 mesh is obtained after the Chinese medicine is removed from impurities, initially pulverized, finely pulverized and sieved;

[0043] (2) Chinese medicine fine powder and medicinal gelatin are mixed evenly by mass ratio 6:1;

[0044] (3) Put the mixture of step (2) into a mold for molding, the temperature of molding is 140°C, the pressure of molding is 25MPa, and the time of molding is 4 minutes;

[0045] (4) Remove the film after molding, and then perform edging treatment, painting and coloring.

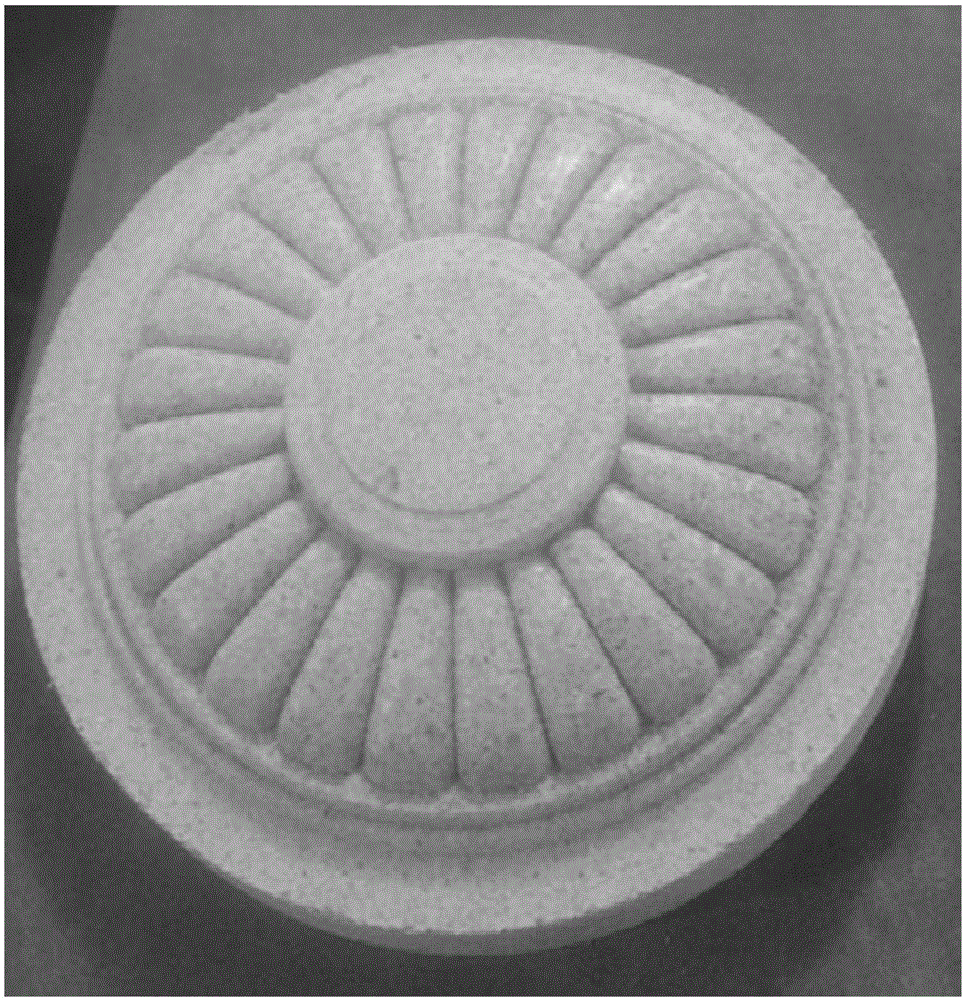

[0046] The prepared traditional Chinese medicine powder model is as follows: figure 1 shown.

Embodiment 2

[0048] Described traditional Chinese medicine fine powder compression molding process comprises the steps:

[0049] (1) Chinese medicine pretreatment; Chinese medicine fine powder with a particle size of 40 meshes obtained after removing impurities, primary crushing, finely pulverizing and sieving the Chinese medicine;

[0050] (2) Chinese medicine fine powder and medicinal gelatin are mixed evenly by mass ratio 5:1;

[0051] (3) Put the mixture of step (2) into a mold for molding, the molding temperature is 100°C, the molding pressure is 15MPa, and the molding time is 6 minutes;

[0052] (4) Remove the film after molding, and then perform edging treatment, painting and coloring.

[0053] The prepared traditional Chinese medicine powder model is as follows: figure 2 shown.

Embodiment 3

[0055] Described traditional Chinese medicine fine powder compression molding process comprises the steps:

[0056] (1) Chinese medicine pretreatment; Chinese medicine fine powder with a particle size of 80 mesh is obtained after removing impurities, primary crushing, finely pulverizing and sieving the Chinese medicine;

[0057] (2) Chinese medicine fine powder and medicinal gelatin are mixed evenly by mass ratio 10:1;

[0058] (3) Put the mixture of step (2) into a mold for molding, the molding temperature is 160°C, the molding pressure is 50MPa, and the molding time is 2 minutes;

[0059] (4) Remove the film after molding, and then perform edging treatment, painting and coloring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com