A production mechanism for multi-layer printed matter

A printed matter and frame technology, applied in the field of multi-layer printed matter production mechanism, can solve problems such as consumers' inability to understand the content of printed matter, poor pasting efficiency, poor effect of overlapping layers, and reduced printing pattern area. Simple, high production efficiency, and reduced production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the examples, and the contents mentioned in the embodiments are not intended to limit the present invention.

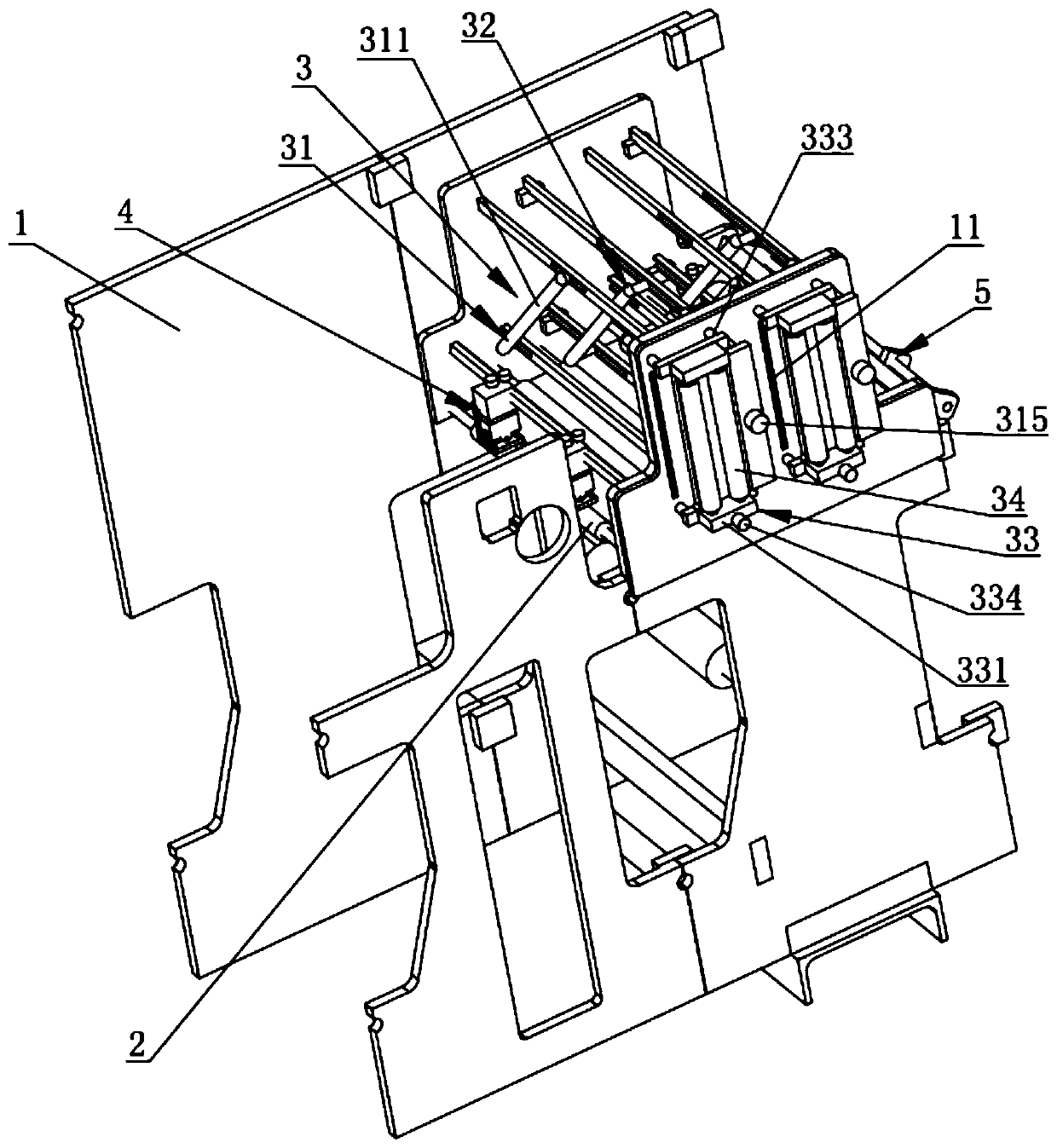

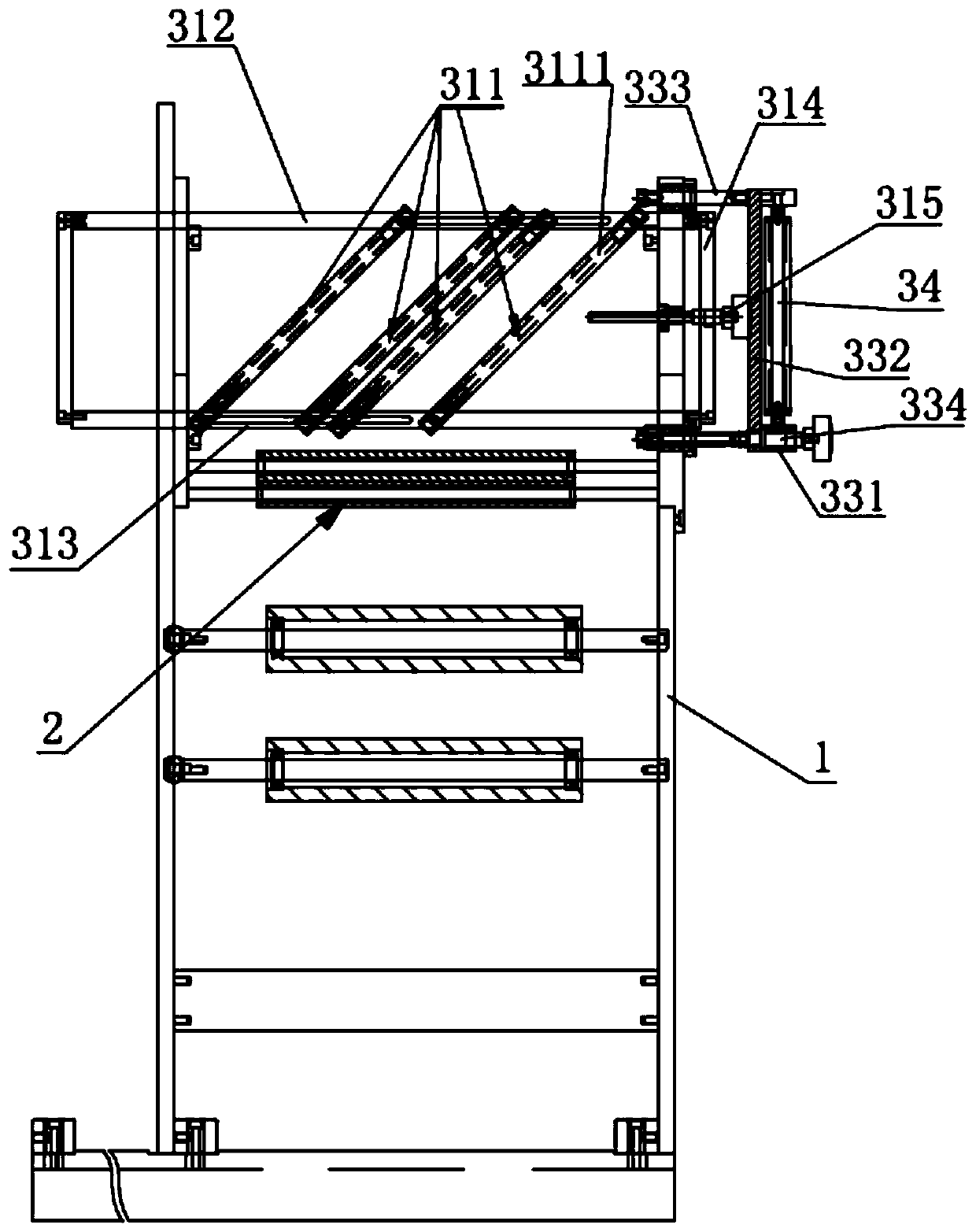

[0020] Such as figure 1 with 2 As shown, a production mechanism for multi-layer printed matter includes a frame 1 and a paper guide roller assembly 2, the paper guide roller assembly 2 is installed on the frame 1, and the frame 1 is equipped with two sets of belt material transposition units 3. The transposition unit 3 includes a first air blowing assembly 31, a second air blowing assembly 32 and two reversed paper guide rollers 34, the first air blowing assembly 31 and the second air blowing assembly 32 are installed on the frame 1 in parallel, reversed The paper guide roller 34 is installed on one side of the frame 1 and is perpendicular to the plane formed by the strip material. The invention has a simple structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com