Rear-row seat folding mechanism capable of giving way backwards

A technology of folding mechanism and rear seat, which is applied to detachable/non-detachable seats, vehicle seats, movable seats, etc., can solve the problems of poor applicability, troublesome operation and high cost, and achieves simple operation and easy production. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

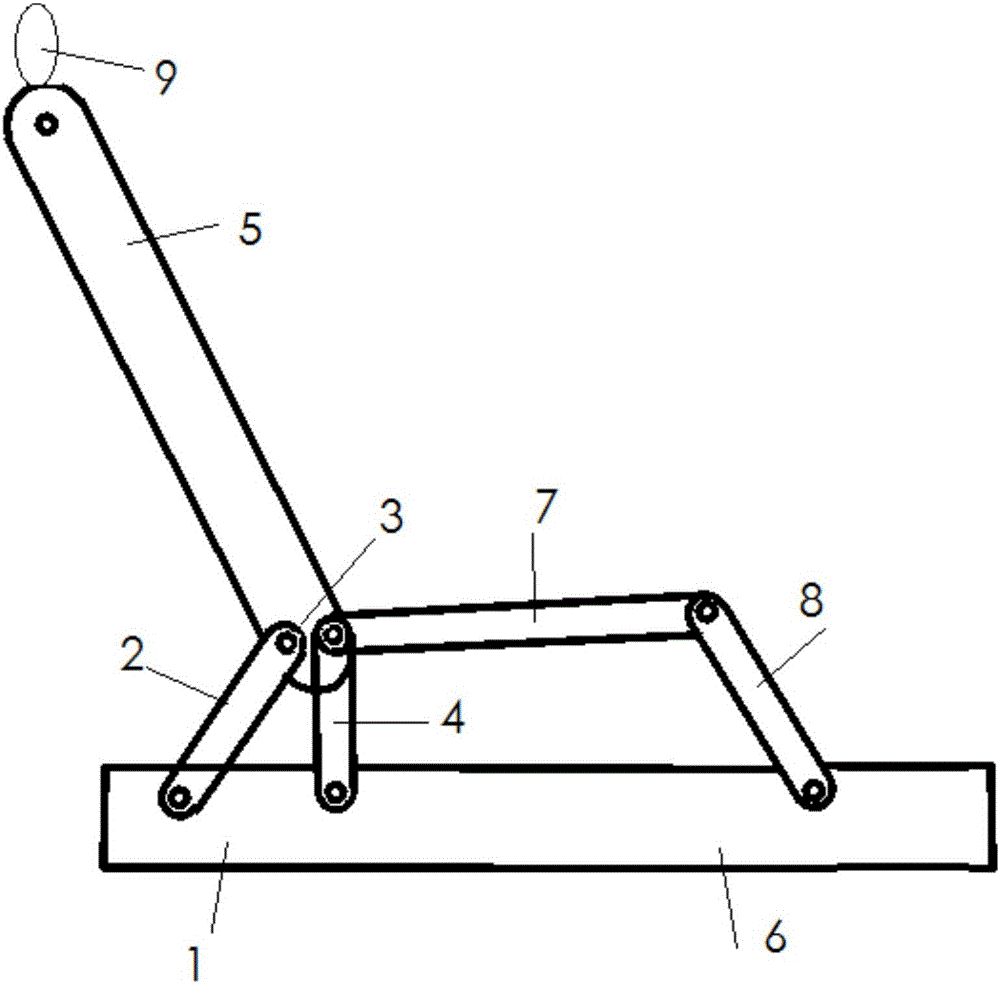

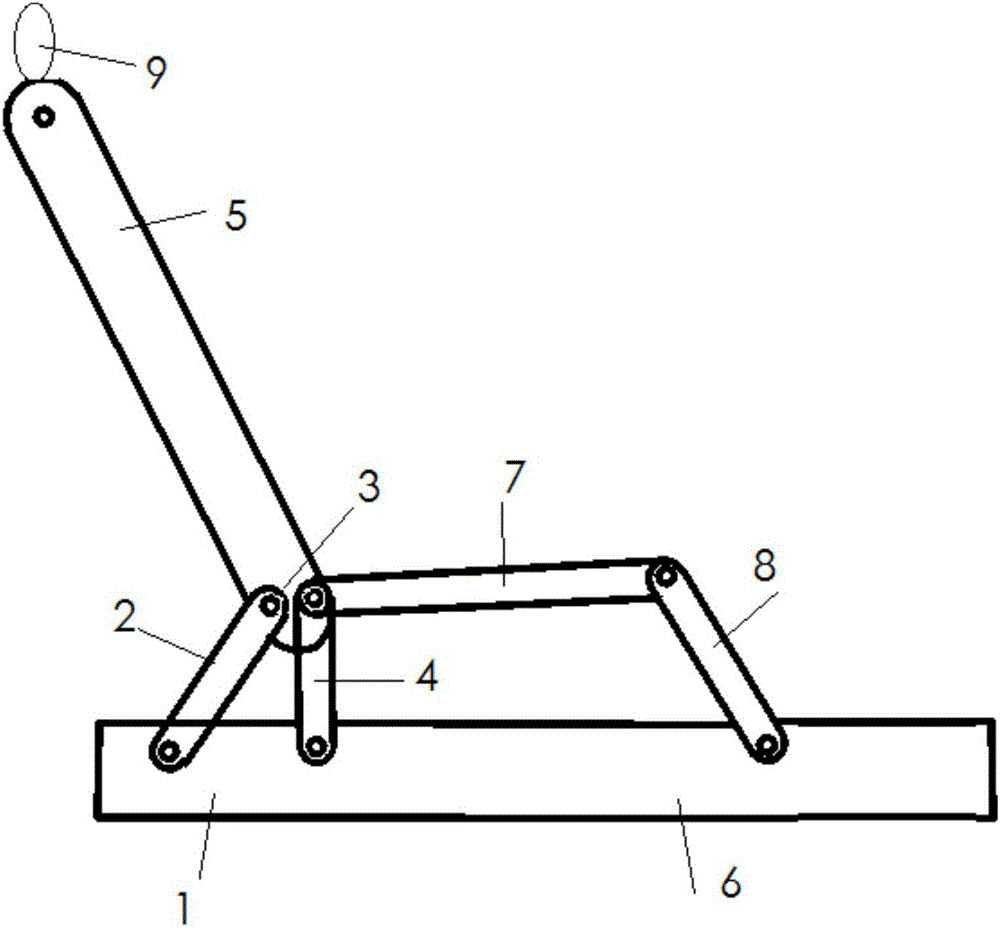

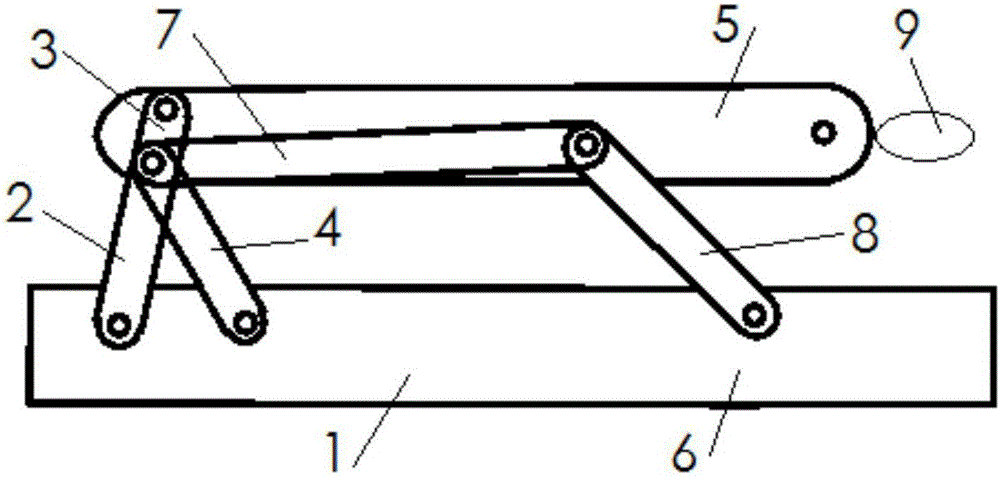

[0027] Embodiment 1: as figure 1 As shown, a rear seat folding mechanism that can give way to the rear, the folding structure is composed of two hinged four-bar mechanisms, both of which are double rocker mechanisms, of which the first hinged four-bar mechanism is composed of Frame one 1, connecting rod one 2, connecting rod one 3 and connecting rod two 4 are sequentially hinged to form, frame one 1 is fixedly connected with the seat base, and connecting rod one 3 is fixedly connected with the support of the seat back 5 as One; the second hinged four-bar mechanism is composed of frame two 6, connecting rod two 4, connecting rod two 7 and connecting rod three 8, and the frame two 6 is fixedly connected with frame one 1 as a whole, connected The rear end of rod two 7 is hingedly connected with the upper end of connecting rod two 4 and the front end of connecting rod one 3, the front end of connecting rod two 7 is hingedly connected with the upper end of connecting rod three 8, a...

Embodiment 2

[0033] Embodiment 2: Let the length of frame one 1 be a, the length of connecting rod one 2 be b, the length of connecting rod one 3 be c, and the length of connecting rod two 4 be d, wherein a=b, d 2 =a 2 +ac+c 2 . The said lengths all refer to the distance between the hinge holes. When the connecting rod-2 and the connecting rod-3 are in a straight line, the angle between the connecting rod-2 and the frame-1 is just 60°, and the rest of the structures are the same as in the embodiment 1. As the hinged four-bar mechanism generally adopts analytical method, graphical method or experimental method in the design, each method has its own advantages and disadvantages. After some appropriate selection and limitation of the length of the member, the design process can be simplified and the design requirements can be guaranteed. ,Improve efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com