Automatic steel plate alignment winding and unwinding device

An automatic technology for rewinding and unwinding, which is applied in the field of steel plate automatic alignment rewinding and unwinding devices, can solve the problems of unstable rewinding force of steel plates, low rewinding efficiency, and affecting rewinding quality, and achieve rewinding efficiency High, reasonable structure design, labor-saving and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

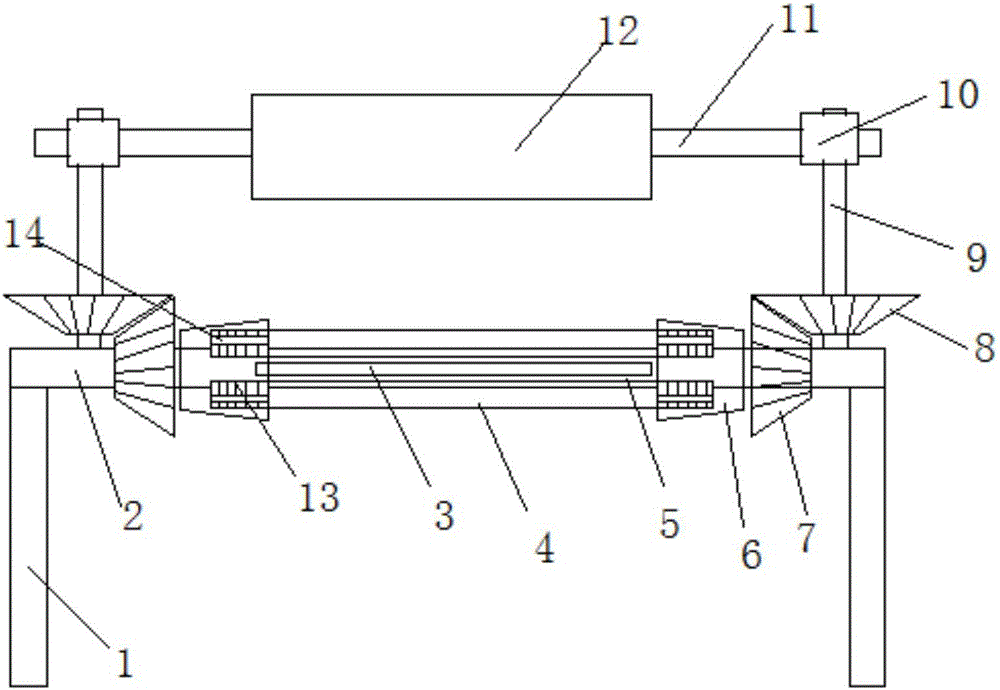

[0019] See attached picture.

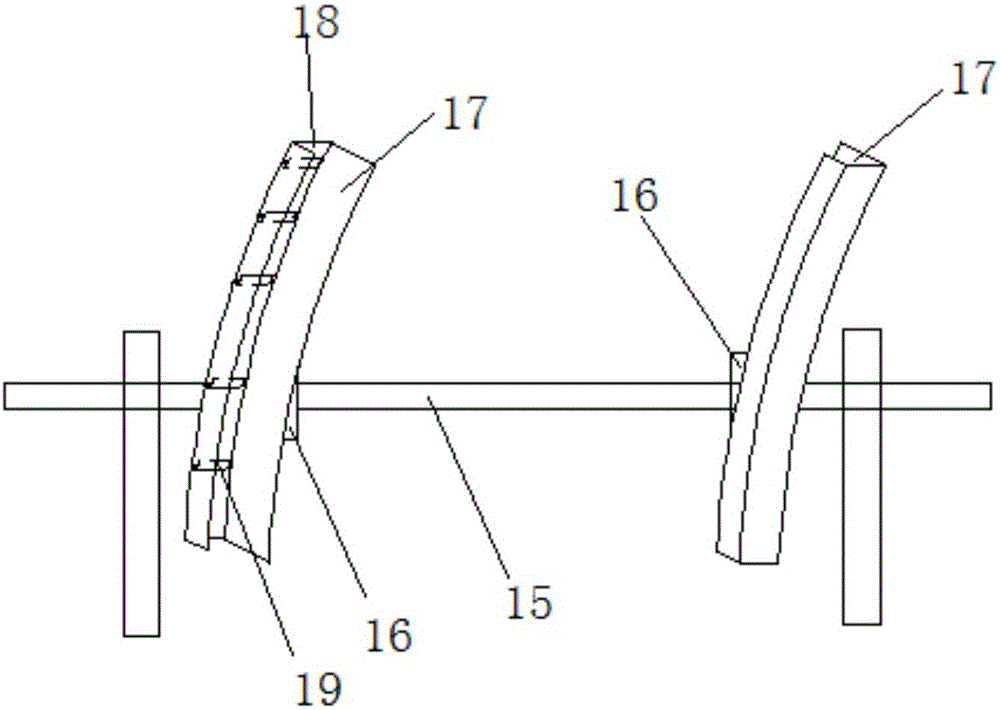

[0020] A steel plate automatic alignment rewinding and unwinding device, including a rewinding shaft 1, the two ends of the rewinding shaft 1 are respectively mounted on brackets 2, an opening 3 along the axial direction is provided on a certain distance of the rewinding shaft 1, and the outside of the rewinding shaft 1 A rewinding card cover 4 is set, and one side of the rewinding card cover 4 is provided with an opening 5, and the two ends of the rewinding card cover 4 are respectively set with a tapered locking sleeve 6; the two ends of the rewinding shaft 1 are respectively installed with The driving bevel gear 7, the driving bevel gear 7 meshes with the driven bevel gear 8 above respectively, and the driven bevel gear 8 is installed on the screw rod 9 on the corresponding side respectively, and the bottom end of the screw rod 9 rotates through the bearing Installed on the support, the screw mandrel 9 is screwed with sliding sleeves 10 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com