Hoisting type opening and closing machine

A hoist and winch-type technology, which is applied in the direction of hoisting devices and clockwork mechanisms, can solve the problems of easy dust absorption, agglomeration, poor lifting movement, etc., and achieves compact structure and good use stability , good dustproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

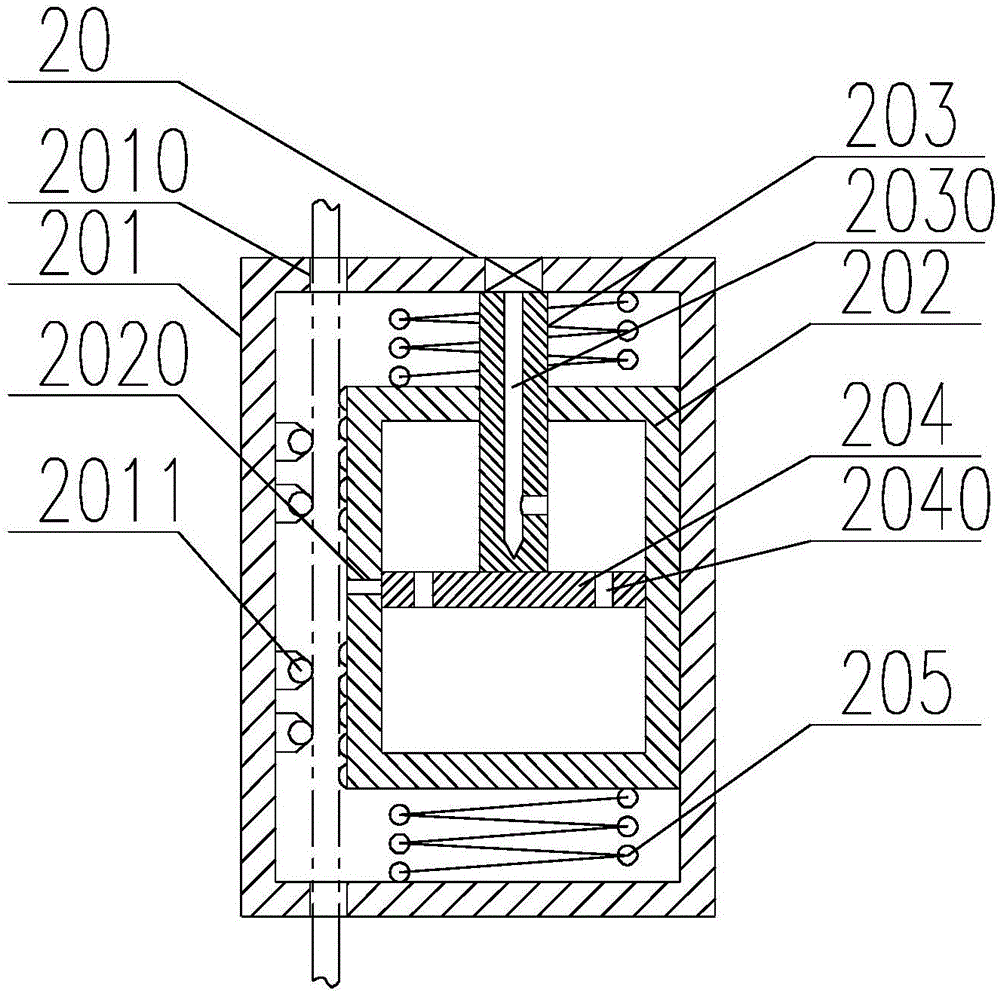

[0048] Embodiment one, such as Figure 4-11 As shown: the forward rotation drive system 53 includes driving gear 1 531, driven gear 1 532, transmission key 1 533, push rod 1 534, pull rod 1 535, combined spring 1 536 and separation spring 1 537, the driving gear A 531 is fixedly connected to one side of the hoisting drum 1 and is coaxial with the hoisting drum 1, the driven gear 1 532 is sleeved on the main shaft 51, and is linked with the driving gear 1 531 through a synchronous belt;

[0049] The main shaft 51 is provided with a chute one 511 located inside the driven gear one 532 and longer than the transmission key one 533, and the lower part of the transmission key one 533 is slidingly connected (a T-shaped, dovetail-shaped sliding structure can be used to Avoid driving key 1 from being thrown out when not combined with driven gear 1) In the chute 1 511, the inner edge of the driven gear 1 532 facing away from the center of the main shaft 51 is provided with a plug compat...

Embodiment 2

[0061] Embodiment two, such as Figure 12-13 As shown: the forward rotation drive system 53 includes a forward rotation motor 538 and a pair of forward rotation trigger blocks 539, and the two forward rotation trigger blocks 539 are fixedly connected to the base 2 and located between two sections of external threads. The forward rotation motor 538 is fixedly connected to the base 2 and detachably connected to the main shaft 51;

[0062] The reverse drive system 54 includes a reverse motor 548 and a pair of reverse trigger blocks 549. The two reverse trigger blocks 549 are fixedly connected to the base 2 and are located outside the two sections of external threads. The reverse motor 548 is fixedly connected to the base 2 and is detachably connected to the main shaft 51;

[0063] The forward rotation motor 538 and the reverse rotation motor 548 are respectively arranged on two sides of the main shaft 51 . When the main shaft rotates forward, the two wiring boards move from ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com