Preparation method of hollow rod-shaped MgF2 particles and application thereof to self-cleaning antireflective film

A technology of hollow rods and particles, applied in the application of self-cleaning anti-reflection film, the field of preparation of hollow rod-shaped MgF2 particles, can solve the problems of glass surface pollution, surface cleaning impossible, and reduce solar energy utilization efficiency, etc., to achieve high transparency Light rate, the effect of avoiding the deterioration of optical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Control magnesium acetate tetrahydrate, HF, total CH 3 The molar ratio of OH is 1:2:250, magnesium acetate tetrahydrate C 4 h 14 MgO 8 The solid was added to anhydrous CH 3 OH, stirred until the solids were completely dissolved, as dispersion A; the HF solution was added to anhydrous CH 3 OH, mixed evenly, as the dispersion B; then the dispersion B was added dropwise to the dispersion A, and the resulting mixed system was transferred to a polytetrafluoroethylene hydrothermal reaction kettle, after 24 hours of hydrothermal heating at 240°C , the solution was taken out after cooling, and a hollow rod-shaped MgF was obtained 2 A sol of particles.

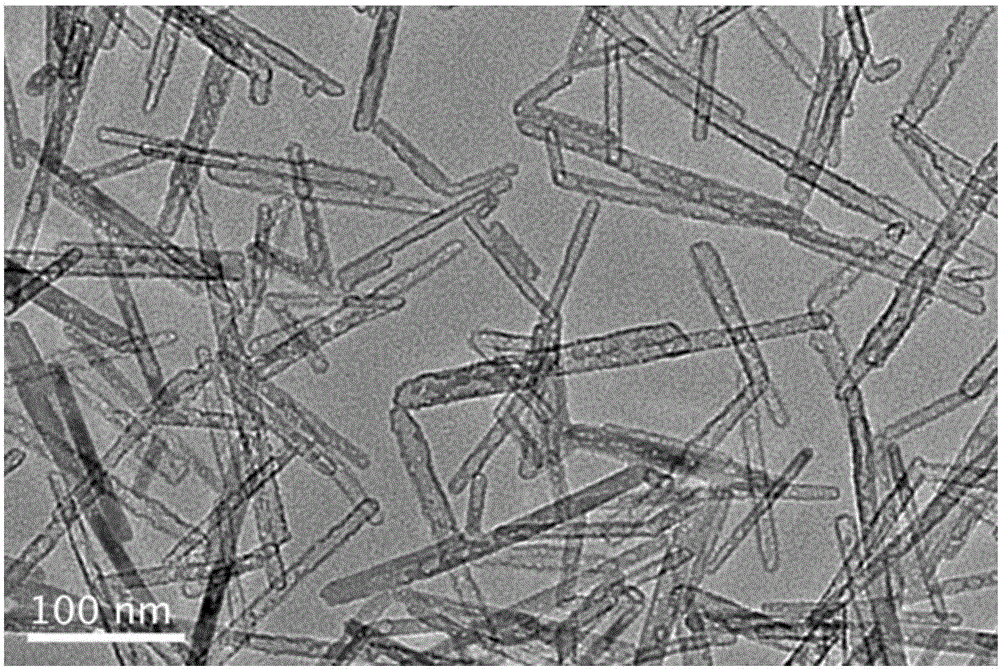

[0025] After detection, the hollow rod-shaped MgF in the above sol 2 The specific shape of the particles is as attached figure 1 shown.

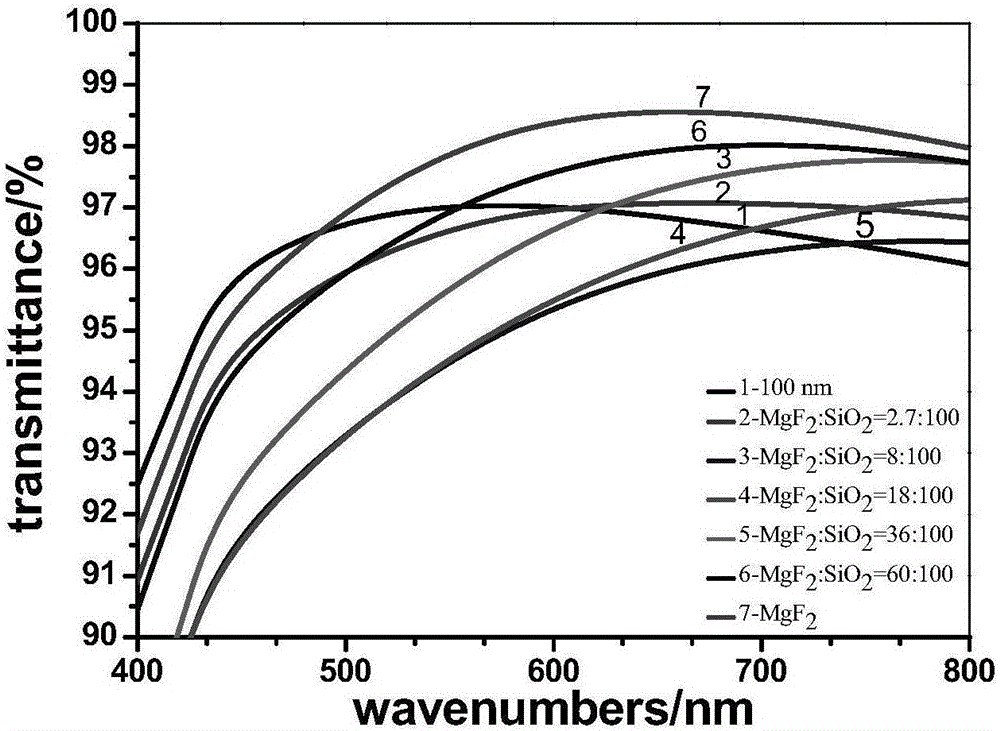

[0026] (1) Add 60ml EtOH, 1ml H to a 100ml beaker 2 O, 3ml NH 4 OH and 2.3ml TEOS were then sealed and stirred in a constant temperature water bath at 30°C for 6 hours, then aged at ...

Embodiment 2

[0048] Hollow Rod MgF 2 The preparation process of the particles is the same as in Example 1.

[0049] (1) Add 114ml EtOH, 2ml H to a 250ml beaker 2 O, 7.12ml NH 4 OH and 3.8ml TEOS were then sealed and stirred in a constant temperature water bath at 30°C for 6 hours, then aged at a constant temperature of 30°C for 3 days; the obtained white sol was placed in a fume hood, and stirred openly to remove ammonia (wet pH test paper was placed close to Just above the mouth of the cup, if the test paper does not change color for a period of time, it means that the ammonia in the sol has been removed), and a solid SiO with a particle size of 50nm is obtained. 2 Nanoparticle sol;

[0050] (2) technology is with embodiment 1,

[0051] (3) technology is with embodiment 1.

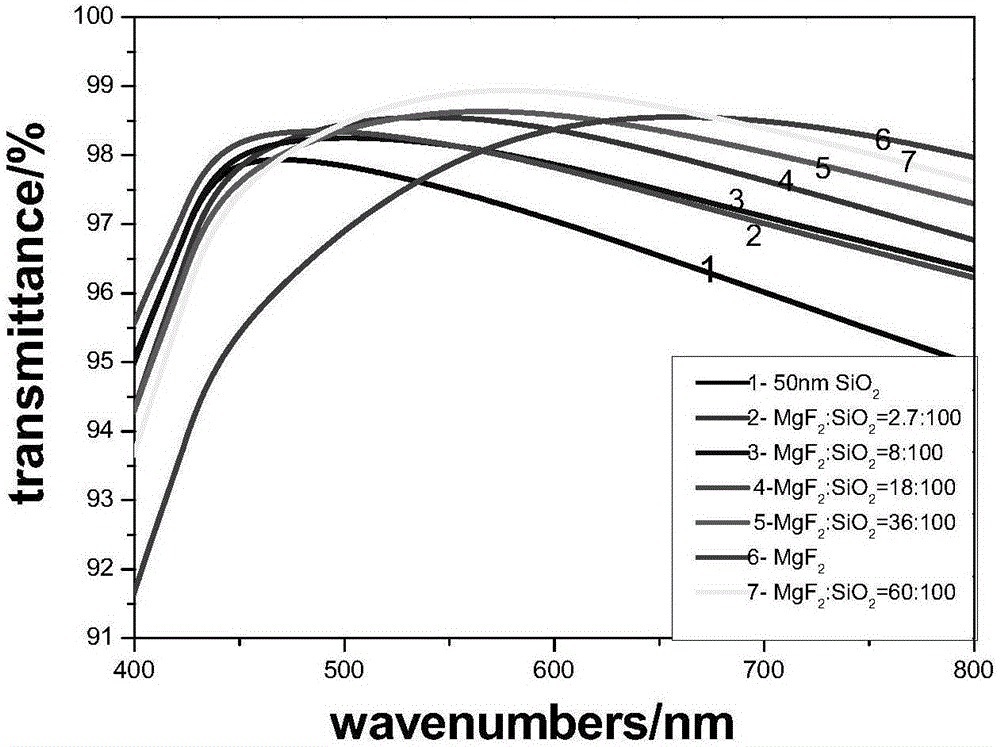

[0052] In step (2), by adding MgF 2 Particles and solid SiO in solution 2 The weight ratio of nanoparticles is adjusted, and the light transmittance of the constructed self-cleaning anti-reflection film is show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap