Vertical lifting, layered turnover and fermenting machine

A vertical elevator and vertical lifting technology, applied in the preparation of vinegar and other directions, can solve problems such as congestion, and achieve the effects of reducing residual volume, simple structure and smooth work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

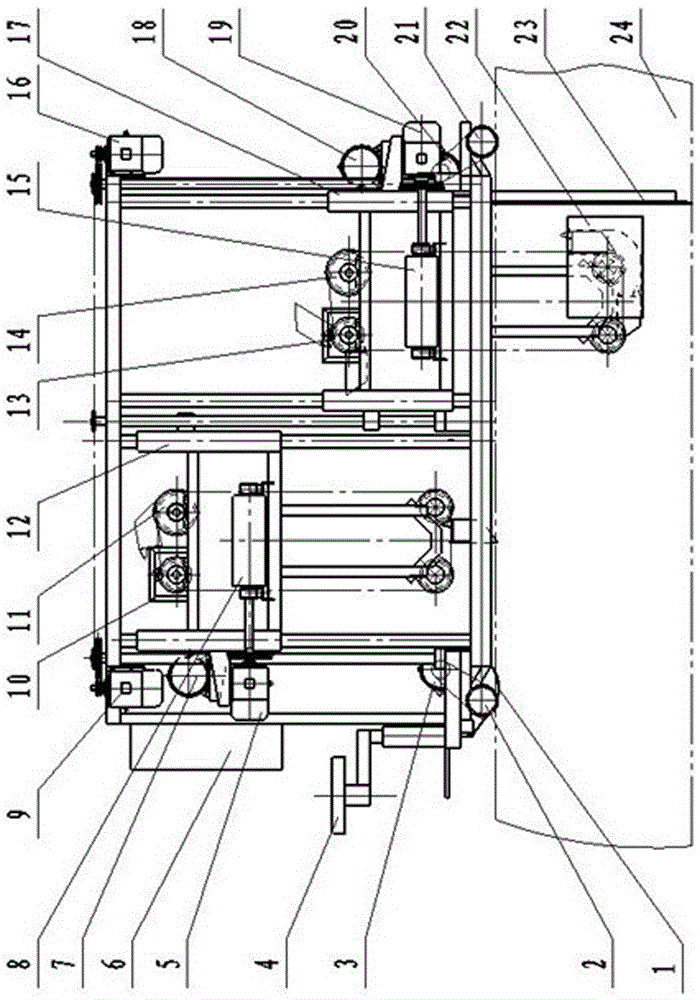

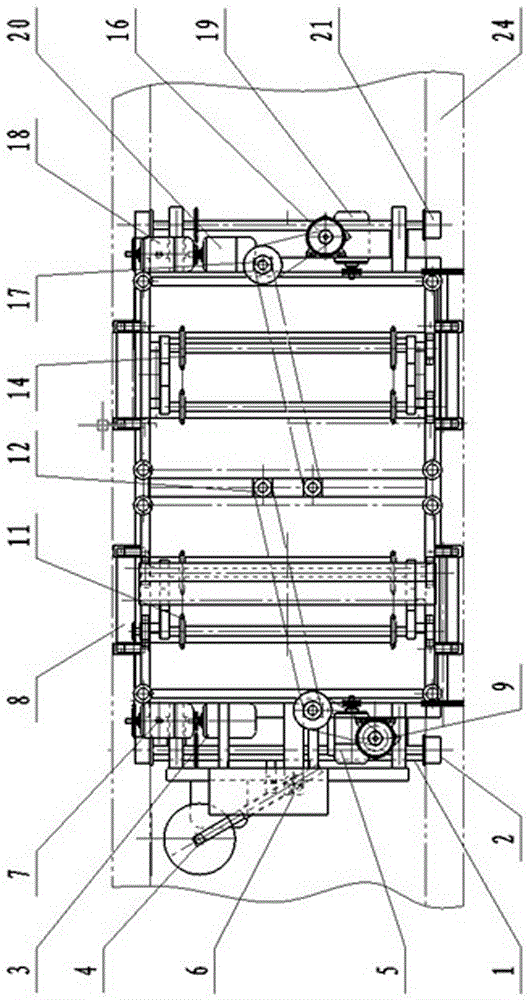

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

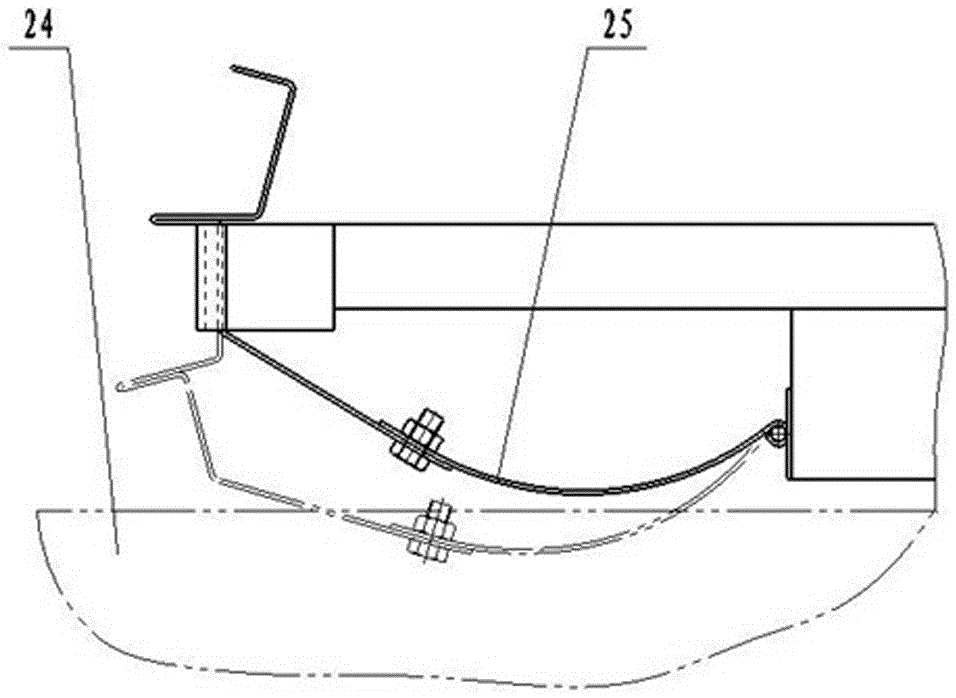

[0022] Turning machine such as Figure 1-2 As shown, it is made up of workbench 4, control box 6, running gear 2, return running gear 21, first working unit, second working unit and unstrained grains clearing mechanism 15. The first operation group consists of the first conveying motor 5, the first fermented grains lifting motor 7, the first lifting motor 9, the first conveying mechanism 8, the first forced bucket buckle mechanism 10, the first fermented grains lifting mechanism 11, and the first lifting mechanism 12 composition. The second operating group consists of a second conveying motor 19, a second lifting motor 18, a second lifting motor 16, a second conveying mechanism 15, a second forced bucket mechanism 13, a second lifting mechanism 14, and a second lifting mechanism 17. , the guide wheel guides the grain loading mechanism 22 to form. Each unit is driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com