Method for controlling ratio of calcium to aluminum of auto sheet ladle top slag to be 1.2-1.8

A technology of top slag calcium aluminum and automobile plate, which is applied in the field of iron and steel smelting, can solve the problem of unsatisfactory control of the top slag calcium aluminum ratio, and achieve the effect of reducing adverse effects and improving the qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

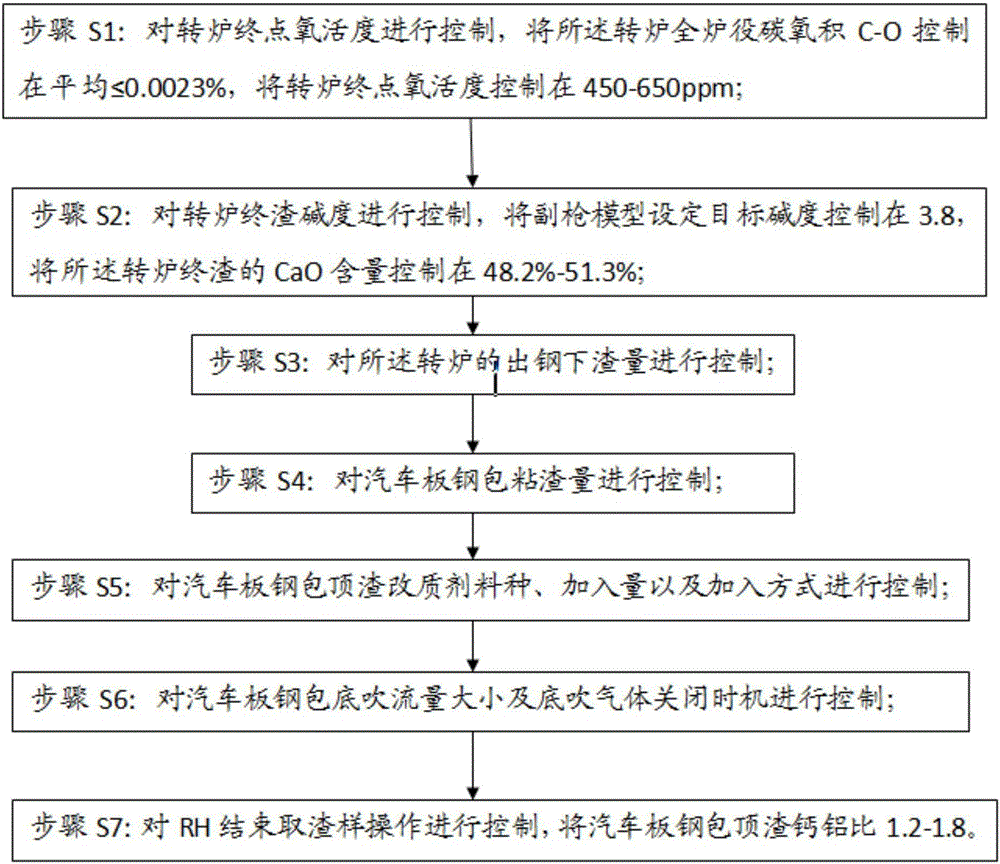

[0059] This embodiment provides a method for controlling the calcium-aluminum ratio of the top slag of the automobile plate ladle to 1.2-1.8, including:

[0060] Step S1: Control the oxygen activity at the end of the converter, control the carbon-oxygen product C-O in the whole furnace of the converter to an average of ≤0.0023%, and control the oxygen activity at the end of the converter to 450-650ppm;

[0061] Step S2: Control the basicity of the final slag of the converter, control the target basicity of the sub-lance model at 3.8, and control the CaO content of the final slag of the converter at 48.2%-51.3%;

[0062] Step S3: controlling the amount of slag discharged from the steel tapping of the converter;

[0063] Step S4: Controlling the amount of slag sticking to the steel ladle of the automobile sheet;

[0064] Step S5: Controlling the type, amount and method of the top slag modifier of the automobile sheet and ladle;

[0065] Step S6: Control the flow rate of the bo...

Embodiment 2

[0108] The difference between this embodiment and Embodiment 1 is that the number of bottom blowing elements described in step SA11 is changed from 12 in the prior art to 4. In step SA43, the post-furnace on-line auto sheet ladle baking is increased, and the proportion of auto sheet steel grades using the number of auto sheet ladles with a baking temperature ≥ 1050° C. is increased from 30% in the prior art to 79.8%. In step S51, the post-furnace slag modifier in the prior art is changed to bauxite, small lime, and high-calcium aluminum slag balls by adding materials such as pre-melted slag, small-grained lime, and high-calcium-aluminum slag balls to optimize the slag modifier materials. In step S52, the amount of slag modifier material added in the prior art is 500Kg of pre-melted slag, 100Kg of small-grained lime and 70Kg of high-calcium-aluminum slag balls, and changed to dynamically adjusted bauxite, small-grained lime and high-calcium-aluminum slag balls ,

[0109] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com