Novel metal surface heat treatment method of oozing nanometer diamond alkene

A technology of nanodiamondene and heat treatment method, applied in metal material coating process, coating, solid-state diffusion coating and other directions, can solve the problems of complex processing process, high equipment requirements, inconvenient machining, etc., and achieves simple and feasible process, Wide application range and convenient finishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A new type of metal surface heat treatment method with nanodiamondene infiltrating, including the following steps:

[0031] 1) The outer surface of the metal parts to be heat treated are covered with a layer of 4mm thick nanodiamondene; first, a clean container that can be sealed is needed, and 4mm thick nanodiamondene is placed on the bottom of the container, and then the metal zero Parts, and then spread a layer of nanodiamondene and then put the parts until the entire container is filled.

[0032] 2) Vacuum the system and introduce reducing protective gas, repeat 3 times, the purpose is to minimize the existence of oxidizing gas;

[0033] 3) Raise the temperature to 100°C above the austenite transformation temperature and keep it for 10 hours, then cool to room temperature with the furnace;

[0034] 4) Take out the metal parts and quench and temper at low temperature. The quenching temperature is the austenite transformation temperature and the low temperature tempering temp...

Embodiment 2

[0043] A new type of metal surface heat treatment method with nanodiamondene infiltrating, including the following steps:

[0044] 1) The outer surface of the metal parts to be heat treated are all wrapped with a layer of 5mm thick nanodiamondene; first, a clean container that can be sealed is needed, and 5mm thick nanodiamondene is laid on the bottom of the container, and then the metal zero Parts, and then spread a layer of nanodiamondene and then put the parts until the entire container is filled.

[0045] 2) Vacuum the system and introduce reducing protective gas, repeat 3 times, the purpose is to minimize the existence of oxidizing gas;

[0046] 3) Raise the temperature to 150°C above the austenite transformation temperature and keep it for 1-20h, then cool to room temperature along with the furnace;

[0047] 4) Take out the metal parts and quench and temper at low temperature. The quenching temperature is 50℃ above the austenite transformation temperature, and the low temperatur...

Embodiment 3

[0056] A new type of metal surface heat treatment method with nanodiamondene. The difference is that in step 1), the outer surface of the metal parts to be heat-treated is covered with a layer of nanodiamondene with a thickness of 4mm; in step 3) the temperature is raised to Austenite Body transition temperature, the rest is the same as in Example 1.

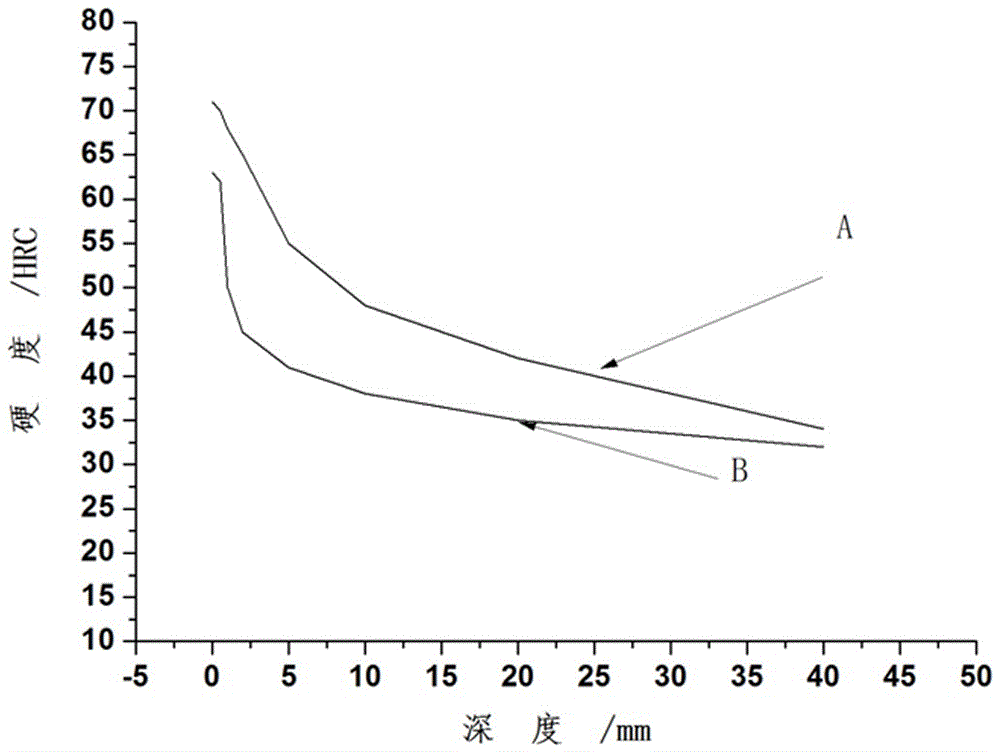

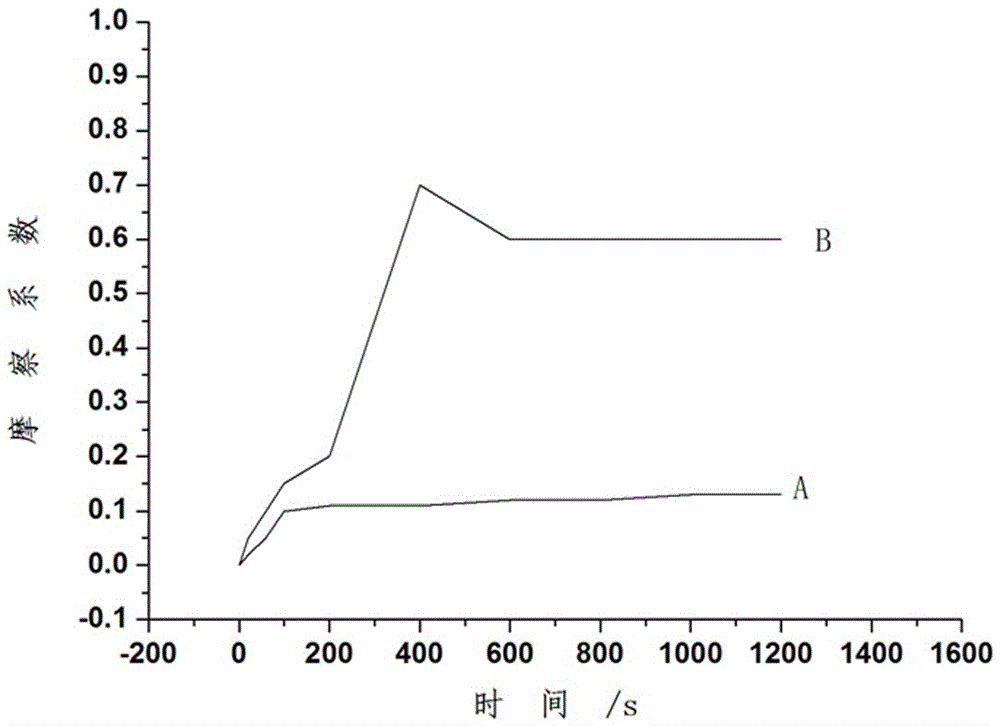

[0057] 1. Experiment and performance testing

[0058] The alloy tool steel Cr12MoV was selected as the test object, and the nano-diamondene treatment and the common carburizing process were carried out according to the present invention, and then their main performance indexes were tested. The results are as follows:

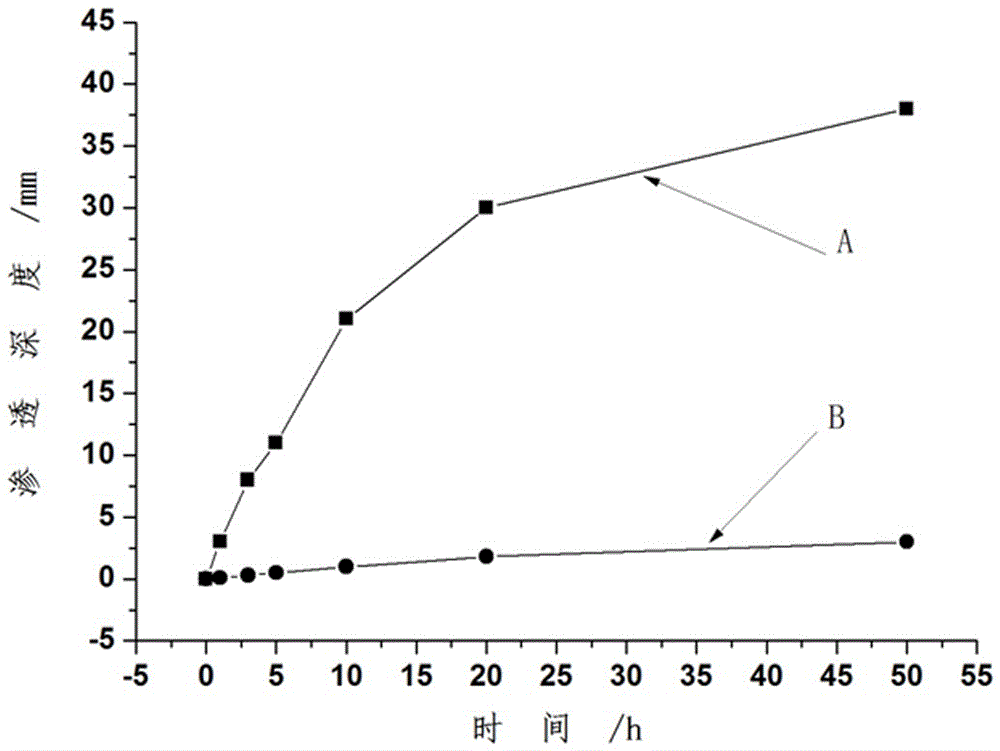

[0059] 1.1 Change in depth of permeable layer with time

[0060] Infiltrate the two samples for 1h, 3h, 5h, 10h, 20h and 50h, and then detect the depth of the seepage layer, and the relationship between the depth of the seepage layer and the penetration time is as follows figure 1 As shown, curve A represents the relation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com