Connecting node for steel pipe constrained steel recycled concrete column and steel beam and construction method thereof

A technology of recycled concrete and connecting nodes, which is applied in the direction of architecture and building structure, can solve the problems of difficult coordination of performance, construction and cost, few node forms, insufficient quantitative research and analysis, etc., to meet the requirements of appearance design, Economical and reliable, conducive to energy saving and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

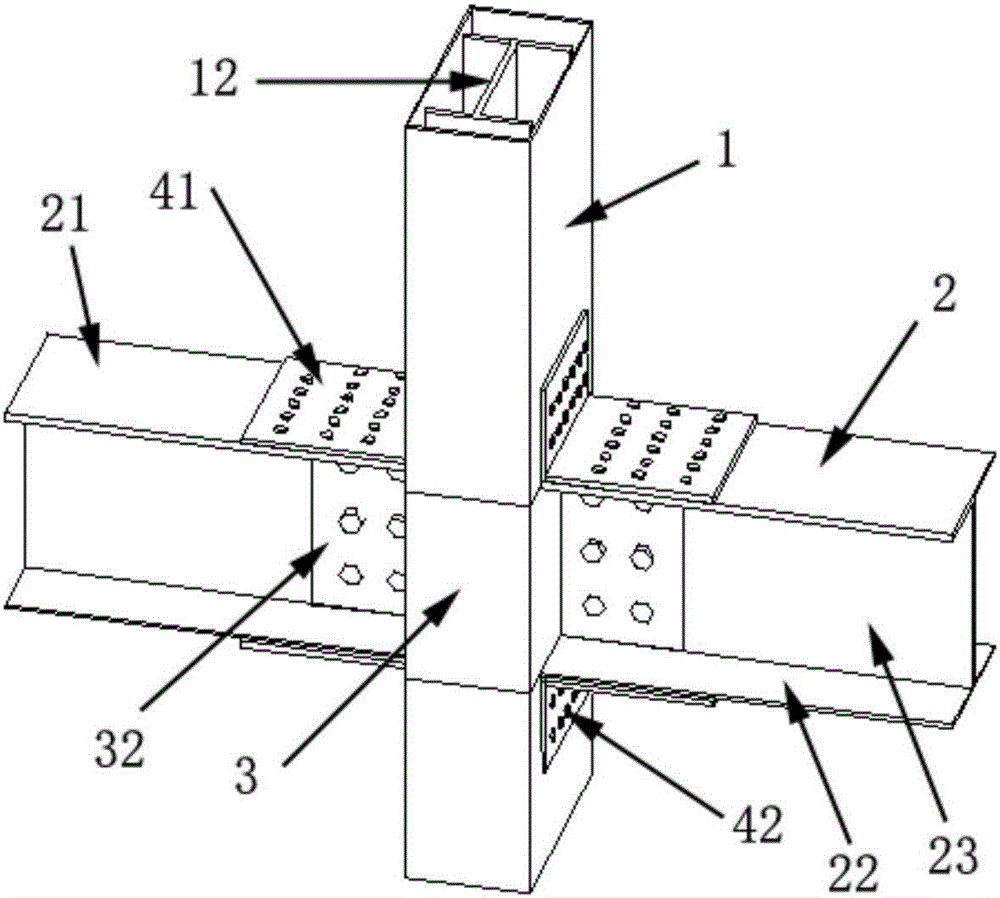

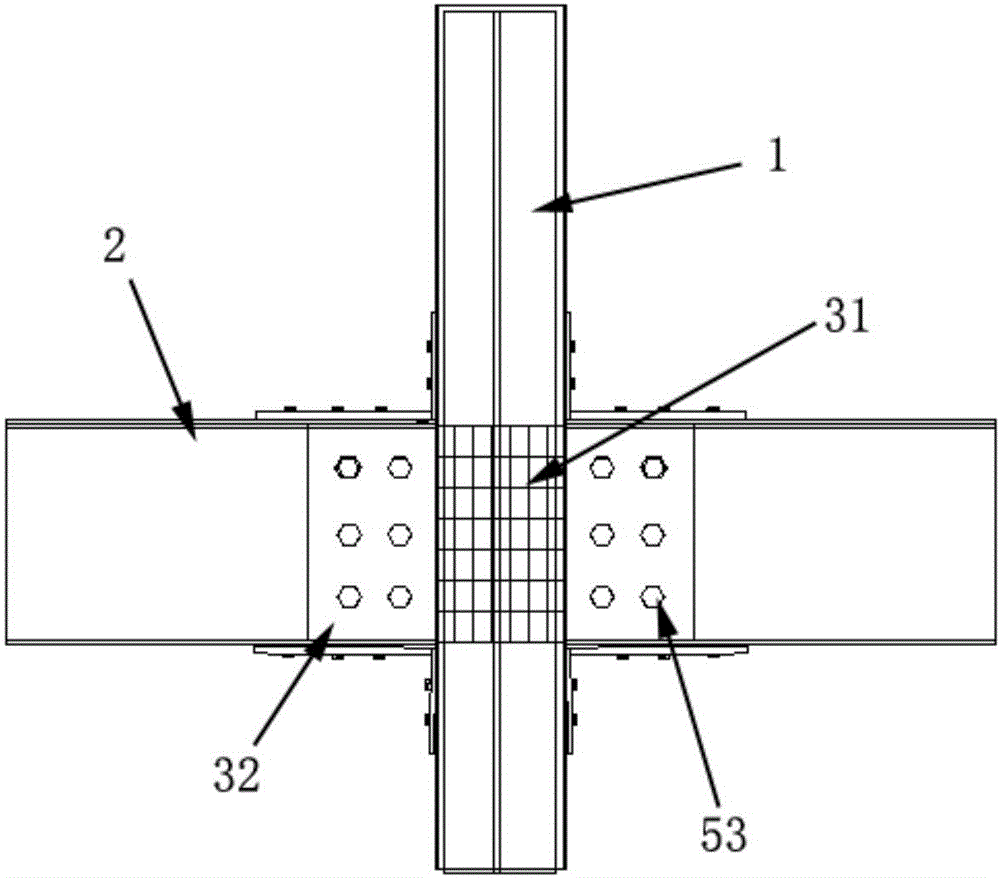

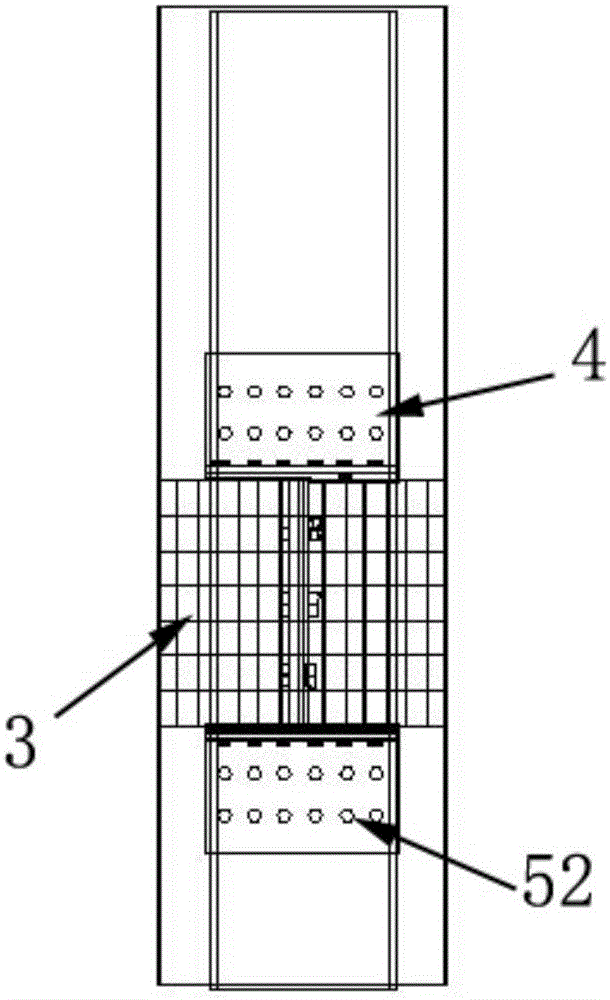

[0035] Such as Figure 1-4 As shown, the joints between steel pipe-constrained steel recycled concrete columns and steel beams include steel pipe-constrained steel recycled concrete columns 1, steel beams 2, jacket clamping pipes 3 and angle steel 4, and the two steel beams 2 are set opposite to each other on the steel pipe-constrained steel recycled concrete On the column 1, the intersection of the steel pipe-constrained steel recycled concrete column 1 and the steel beam 2 forms a node domain. The angle 4 comprises two top angles 41 and two bottom angles 42 . At the node domain, the upper flange 21 of each steel beam is connected to the horizontal plate of a top angle steel 41 through first high-strength bolts 51, and the lower flange 22 of each steel beam is respectively connected to the horizontal plate of a bottom angle steel 42. The plates are fastened and connected by the first high-strength bolts 51, the vertical plates of the two top angle steels 41 are fastened and ...

Embodiment 2

[0046] Such as Figure 5As shown, the joints between steel pipe-constrained steel recycled concrete columns and steel beams include steel pipe-constrained steel recycled concrete columns 1, a steel beam 2, jacket clamping pipe 3 and angle steel 4, and steel beam 2 is set on steel pipe-constrained steel recycled concrete columns 1 , the intersection of the steel pipe-constrained steel recycled concrete column 1 and the steel beam 2 forms a node domain. The angle steel 4 comprises a top angle steel 41 and a bottom angle steel 42 . At the node domain, the upper flange 21 of the steel beam 2 is fastened to the horizontal plate of a top angle steel 41 through the first high-strength bolt 51, and the lower flange 22 of the steel beam 2 is connected to the horizontal plate of a bottom angle steel 42 through the first High-strength bolts 51 are tightly connected. The steel pipe-constrained steel recycled concrete columns 1 are respectively fastened and connected to the vertical plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com