Energy consumption spherical support base

A technology of spherical bearings and bearing plates, which is applied in bridges, shockproof, bridge parts, etc., can solve the problems of weak energy dissipation capacity, affecting structural safety, and increasing structural displacement response, and achieves low sealing performance requirements, Excellent vibration damping ability, strong energy dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

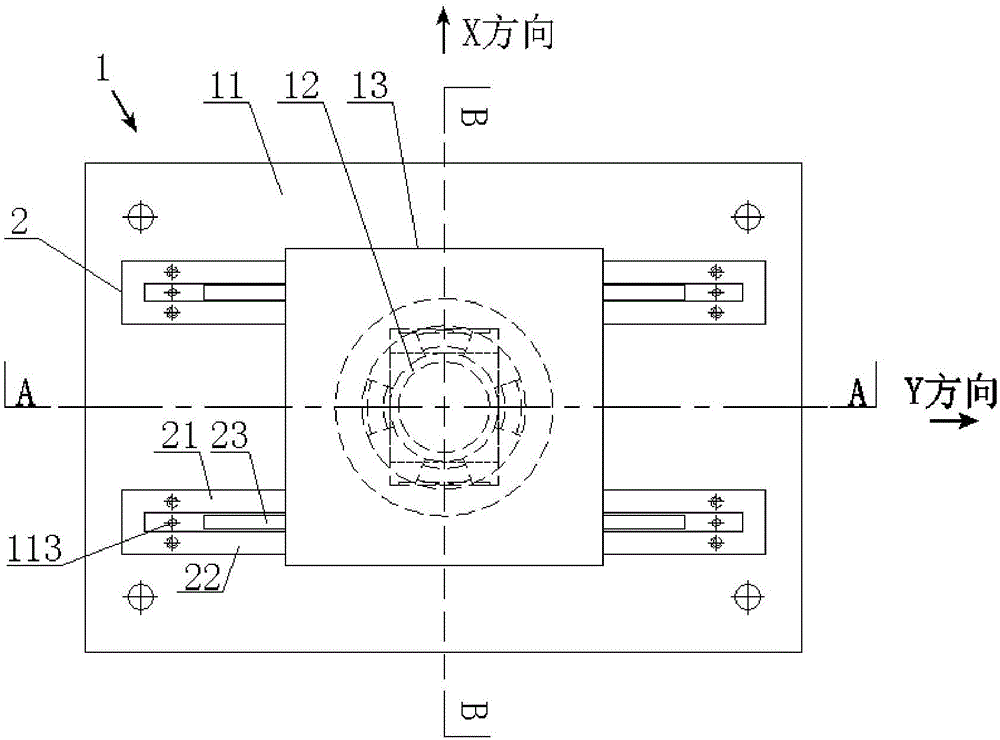

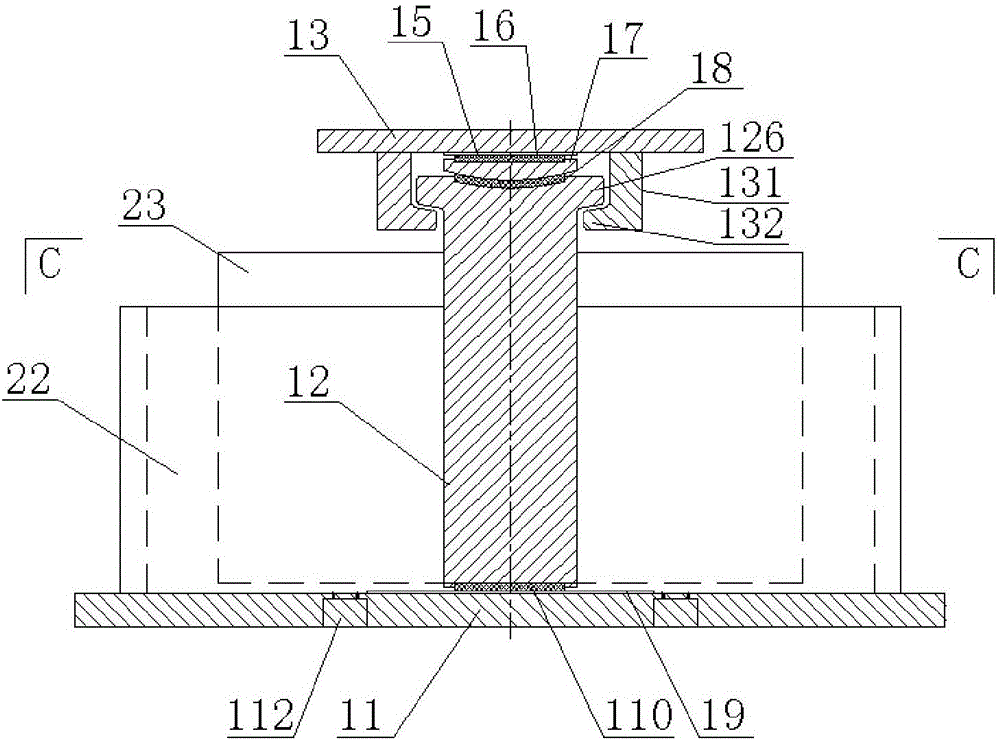

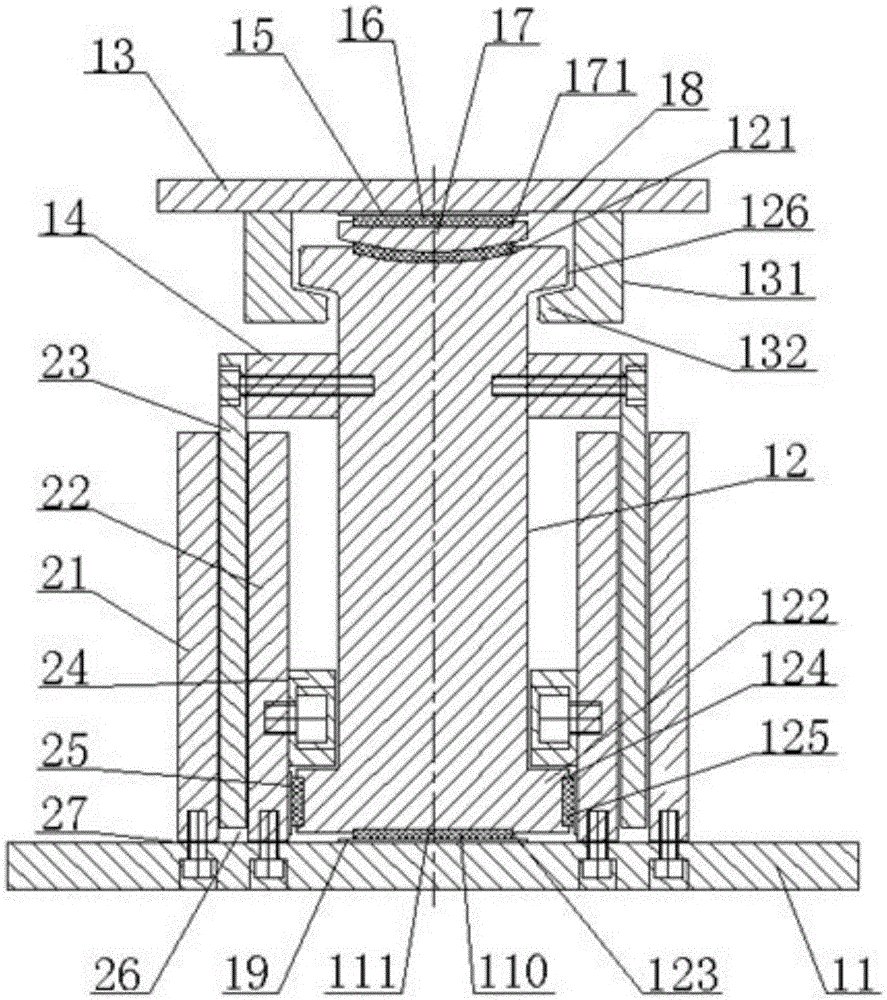

[0032] Such as Figure 1 to Figure 3 As shown, the energy-dissipating spherical bearing of the present invention includes a spherical bearing 1 that can slide in one direction and a damping wall 2 arranged on the spherical bearing 1; the spherical bearing 1 includes a lower bearing plate 11, The middle body 12 arranged on the lower support plate 11, the upper support plate 13 arranged on the middle body 12, the bottom surface of the damping wall 2 is fixed on the top surface of the lower support plate 11 , the upper end of the damping wall 2 is fixedly connected with the intermediate body 12 .

[0033] Such as Figure 1 to Figure 3 As shown, the damping wall 2 includes a first fixed wall 21, a second fixed wall 22 parallel to the first fixed wall 21 and a sliding sliding wall arranged between the first fixed wall 21 and the second fixed wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com