Composite noise-reduction muffler plate

A sound-absorbing panel and sound-absorbing cotton technology, which is applied in the direction of sound insulation, building components, building components, etc., can solve problems such as noise reduction, achieve good noise reduction effects, and facilitate assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

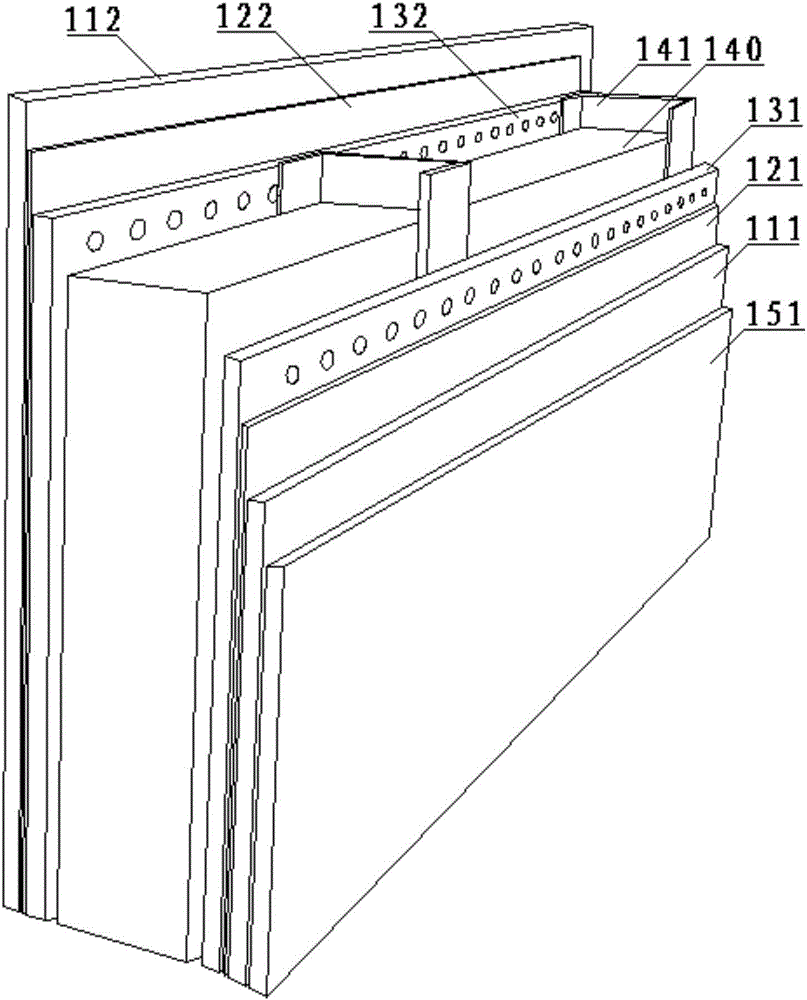

[0010] Such as figure 1 As shown, the schematic diagram of the composite noise-reducing sound-absorbing panel of the present invention. Composite noise-reducing sound-absorbing panels include flame-retardant gypsum board A, sound-absorbing non-woven fabric A, flame-retardant sound-absorbing orifice A, sound-absorbing cotton layer, flame-retardant sound-absorbing orifice B, sound-absorbing non-woven B, and flame-retardant gypsum board laminated in sequence B, flame-retardant gypsum board A, sound-absorbing non-woven fabric A, flame-retardant sound-absorbing orifice A, sound-absorbing cotton layer, flame-retardant sound-absorbing orifice B, sound-absorbing non-woven B, flame-retardant gypsum board B tightly pressed to form a composite noise reduction The sound-absorbing panel as a whole. This scheme can adopt the way of bonding and pressing, and can also use the way of bolt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com