Multi-stage perforation initiation method for oil and gas wells based on rapid pressure detection

A detonation method and technology for oil and gas wells, applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve problems such as repeated pressure detection, achieve the effects of preventing repeated detection, improving success rate, and overcoming interference effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

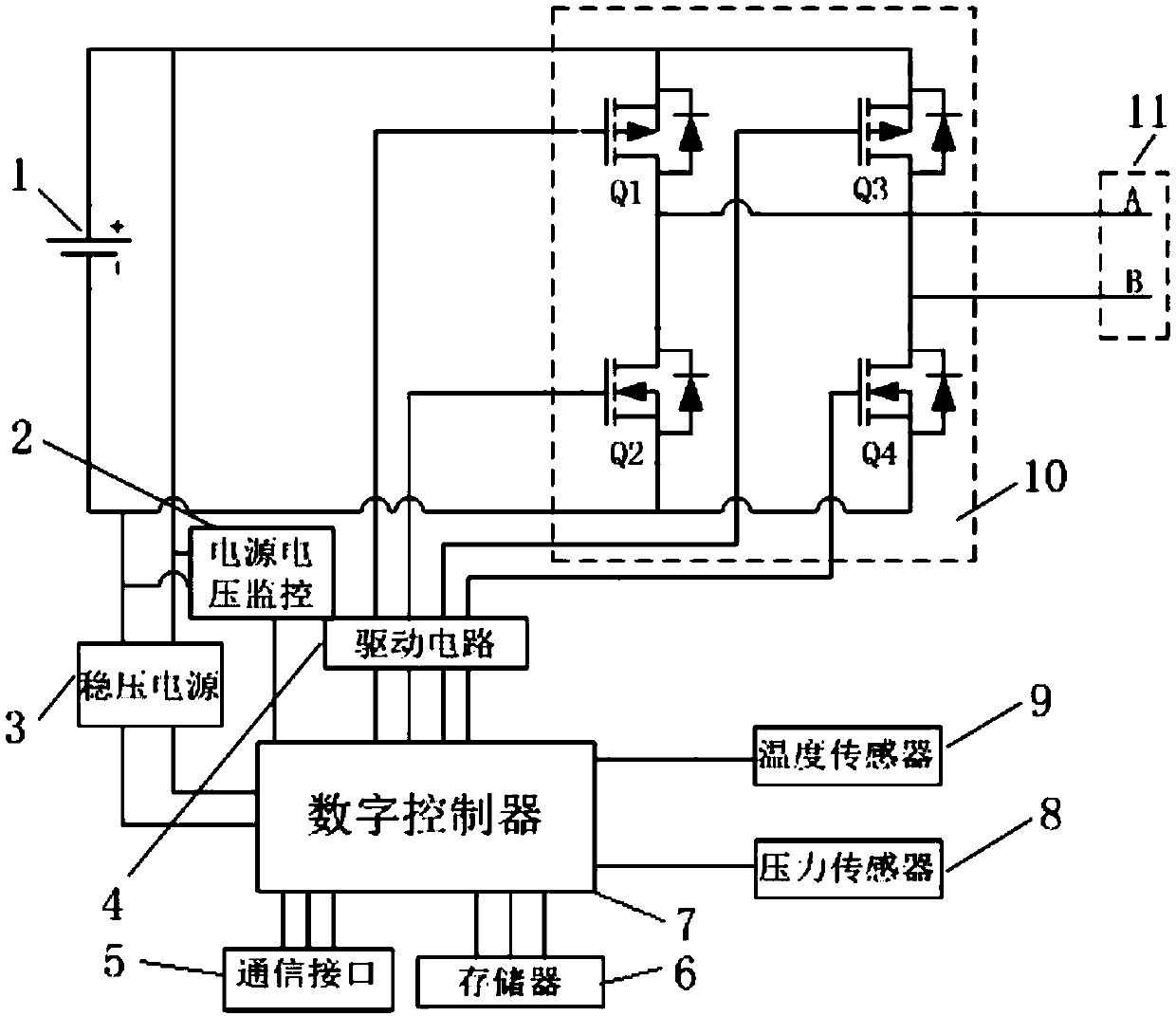

[0034] The multistage perforation detonation method for oil and gas wells based on rapid pressure detection in the present invention adopts figure 1 The control circuit structure of the oil and gas well multi-stage perforation detonator shown (see the patent "Control circuit and control method of oil and gas well multi-stage perforation detonator", application date: 2014.5.6, application number: 2014101889681), wherein, Including power supply 1, power supply voltage monitoring 2, regulated power supply 3, drive circuit 4, communication interface 5, memory 6, digital controller 7, pressure sensor 8, temperature sensor 9, positive and negative voltage conversion circuit 10, output terminal 11.

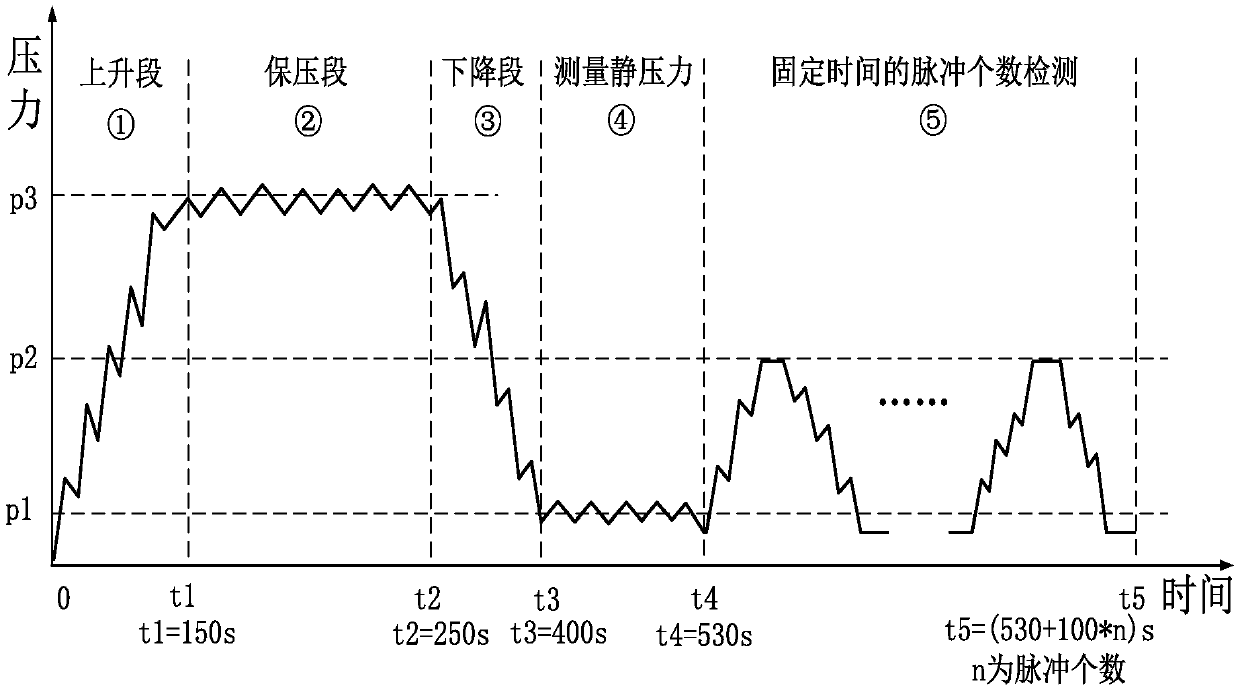

[0035] In order to improve the accuracy of command recognition, in view of the problems of slow pressure change and gas leakage in old wells, the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com