Semi-automatic cleaning device for floor rocks of tunnel floor heave region

A semi-automated and clearing device technology, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve the problems of time-consuming and labor-intensive manual processing, hinder transportation and pedestrians, and affect work efficiency, so as to achieve convenient installation, liberate manpower, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

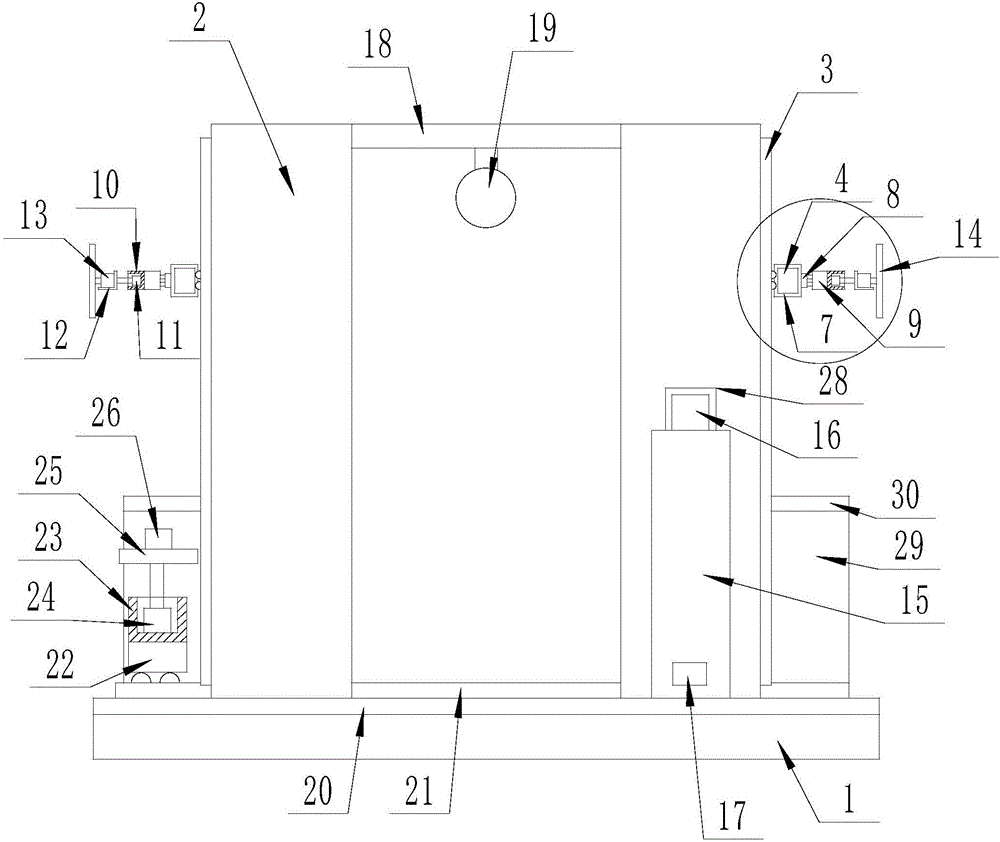

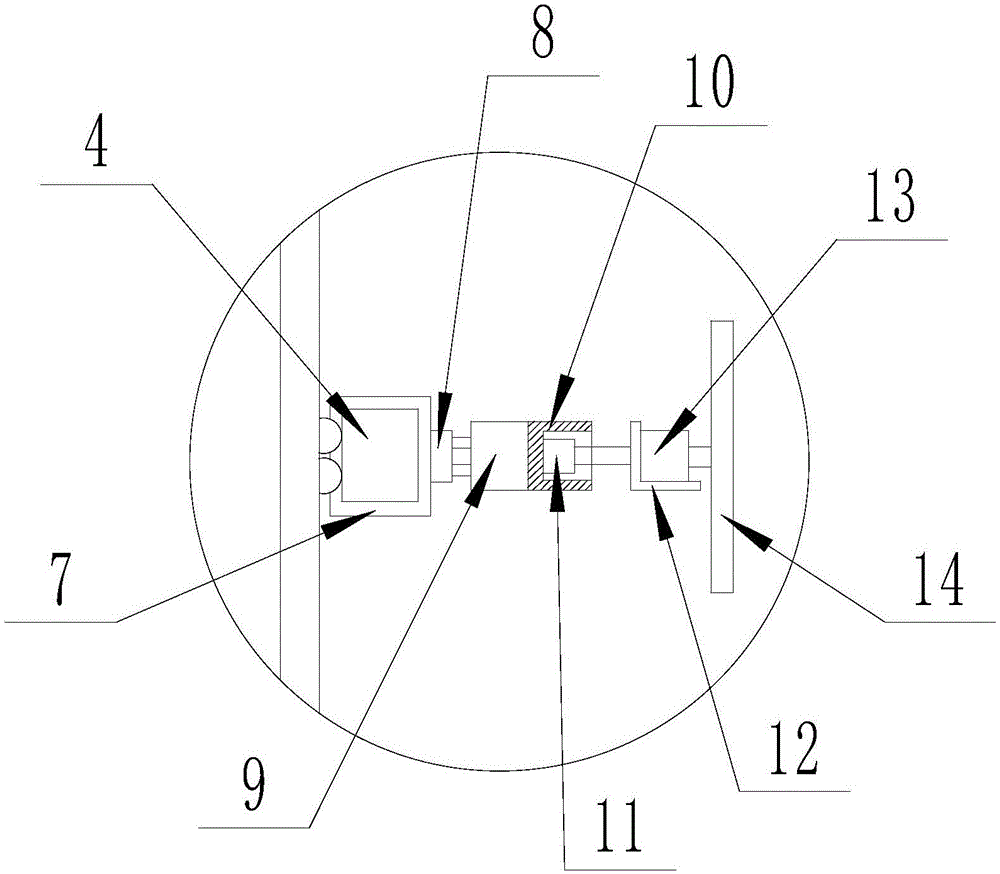

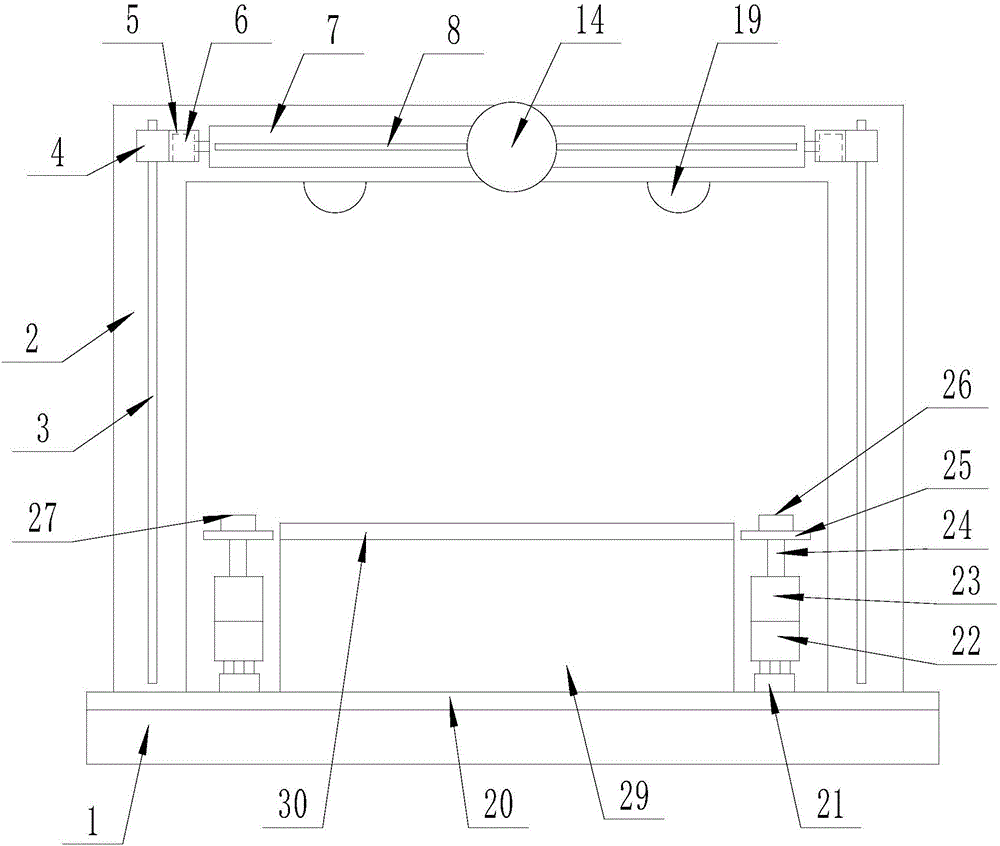

[0017] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a semi-automatic removal device for floor rocks in the bottom sill area of the roadway includes a bearing plate (1), and the upper surface of the bearing plate (1) is provided with a cutting mechanism, and the cutting mechanism is arranged on the bearing plate (1). One group of door-shaped support frames (2) on the surface, one group of vertical slide rails (3) arranged on the two legs of each door-shaped support frame (2), and one group of vertical slide rails (3) arranged on each vertical slide rail (3) The No. 1 electric trolley (4), the mouth-shaped mounting frame (5) arranged on the side surface of each No. 1 electric trolley (4), the mouth-shaped mounting frame (5) arranged on the inner lower surface of each mouth-shaped mounting frame (5) and the rotating end is horizontal The No. 1 rotating motor (6), the rectangular mounting plate (7) arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com