A parallel-flow radial organic working fluid power generation expander and its installation method

An expander and organic technology, which is applied in the field of parallel-flow organic working medium power generation expanders, can solve the problems of complex internal structure, working medium leakage, and low efficiency, so as to improve power generation efficiency, avoid working medium leakage, and ensure good sealing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

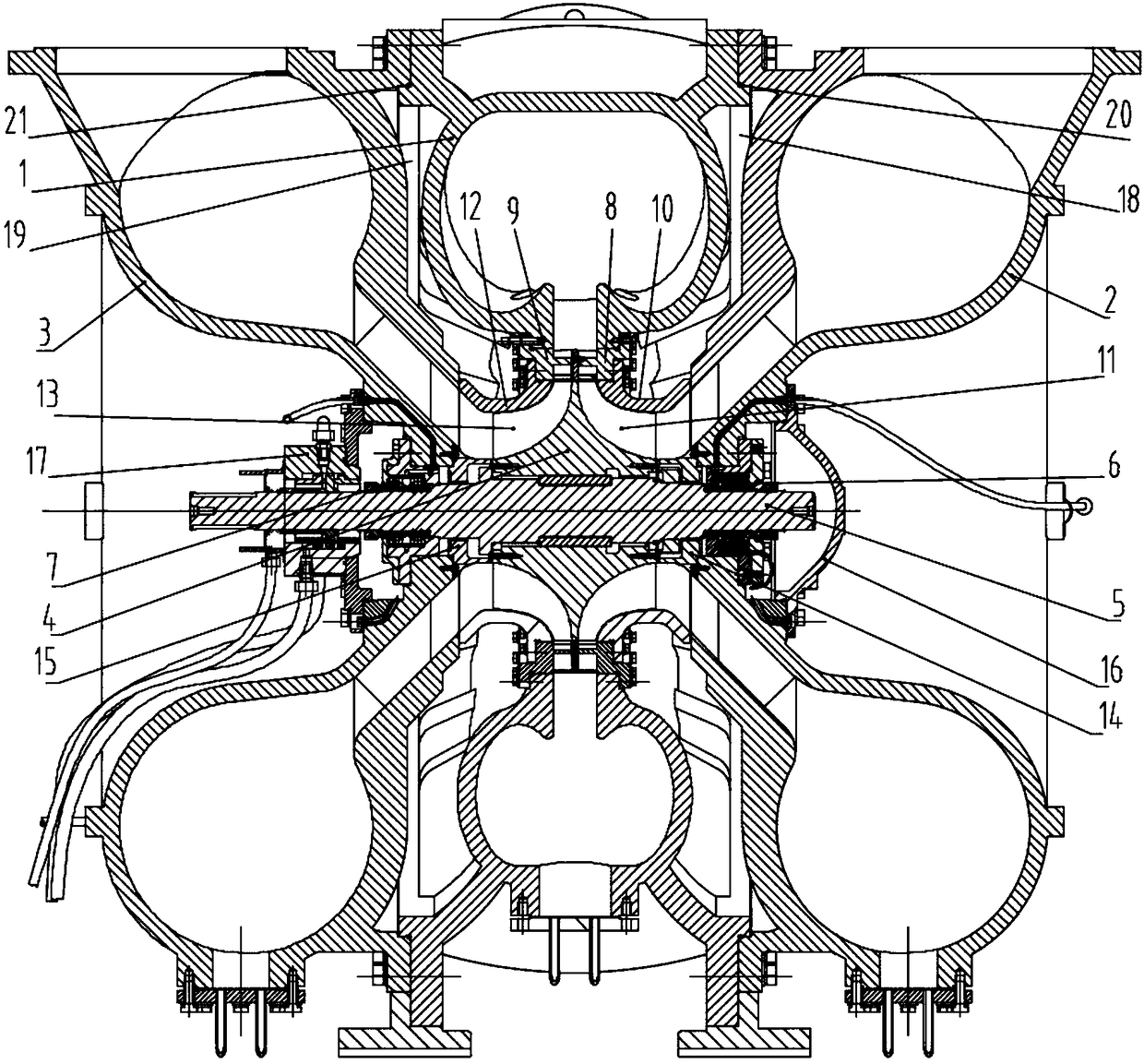

[0014] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] see figure 1 , an embodiment of the co-current flow-to-heart type organic working medium power generation expander, including an air intake shell 1, on which the first exhaust shell 2 and the second exhaust shell 3 are installed in parallel, and also includes a fixed The main shaft 5 of the turbine 4, one end of the main shaft 5 is supported by the first bearing 6 installed on the first exhaust casing 2, and the other end of the main shaft 5 is supported by the second bearing 7 installed on the second exhaust casing 3, and the The output end of the air casing 1 is fixed with a first nozzle ring 8 and a second nozzle ring 9 for adjusting the direction and speed of the airflow, and the first nozzle ring 8 is fixed with a first impeller casing 10 forming a first flow passage 11 with the turbine 4 , the first flow channel 11 communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com