Single-panel or multi-panel fabrication

一种面板、构件的技术,应用在i)组合式面板结构,指导叶或转子叶片翼型件领域,能够解决CMC系统破坏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

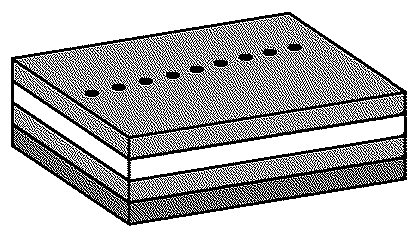

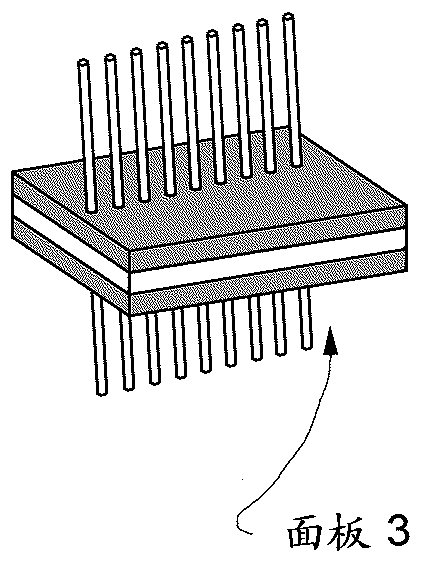

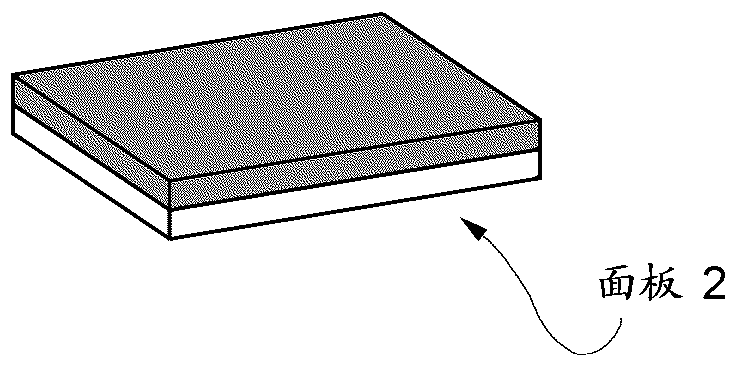

[0129] The figures of this description illustrate various embodiments of single and / or multi-ply CMC panels provided for system arrangements. Basically, CMC panels can be designed with individualized fiber structures according to operational requirements. A proportion of fibers may have different diameters, which are intended to carry mechanical loads (in the case of larger diameters) and thermal stresses mainly during flow application operations.

[0130] Figure 4 shows various examples of panel combinations. In general, a panel means an arrangement of plies or a woven fibrous structure. Figure 4a ) shows a standard CMC panel, also referred to as Panel 1, using a standard arrangement and / or woven fiber structure. The different layers in a multi-layer panel do not necessarily have the same fiber orientation or weave architecture. according to Figure 4b ) brings together a standard CMC panel (made from one of several plies of standard ceramic tissue) and a "cooling patter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com