A Super Knock Suppression Method Based on Multi-parameter Regulation

A super detonation and multi-parameter technology, applied in electrical control, engine control, fuel injection control, etc., can solve problems such as engine damage, achieve the effect of increasing scavenging intensity, avoiding high exhaust temperature, and improving engine torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

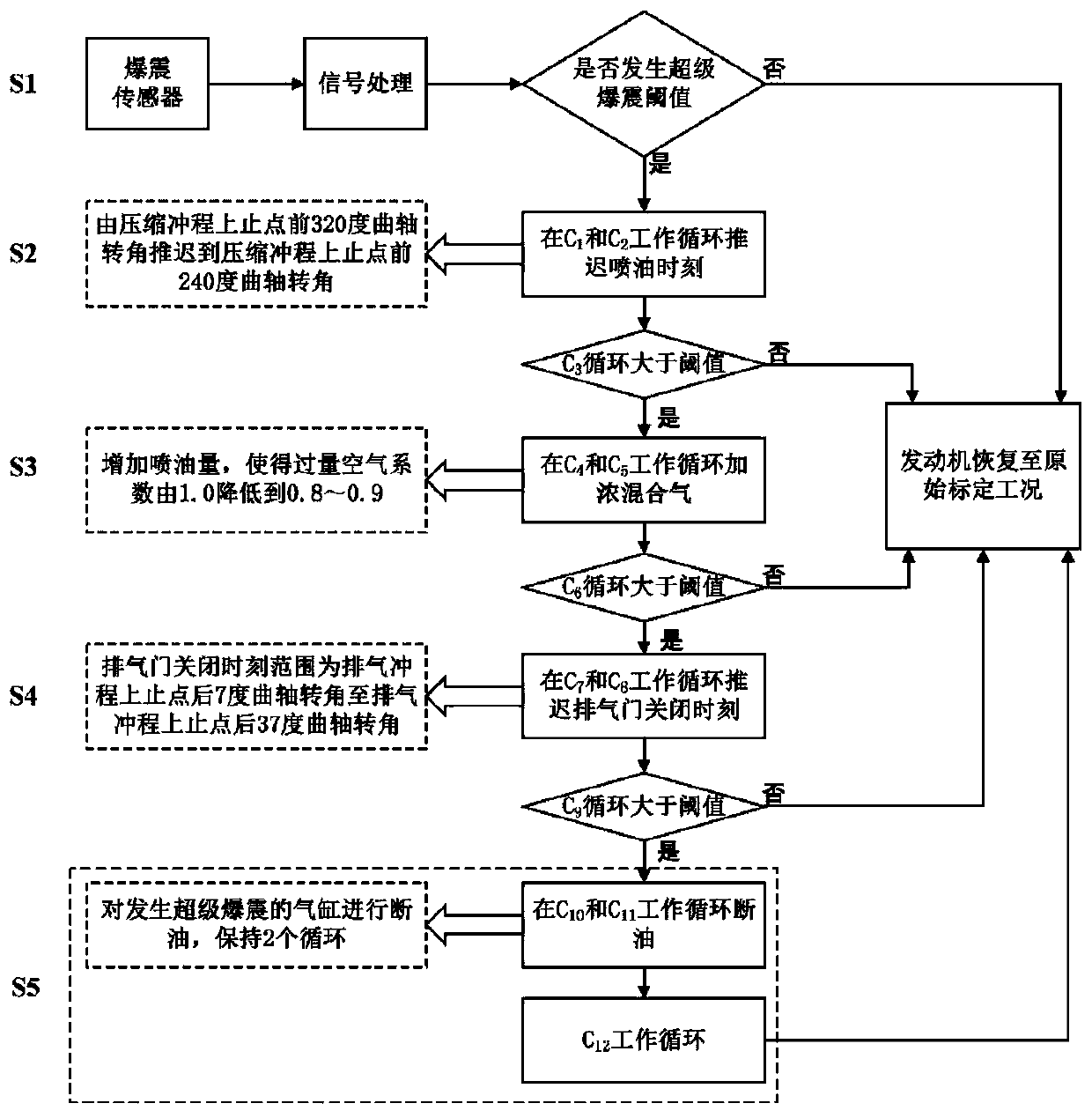

[0026] The present invention will be further described below in conjunction with the accompanying drawings, and n=2 is selected in a specific embodiment of the present invention.

[0027] The invention provides a method for suppressing super-knock based on multi-parameter regulation, the method comprising:

[0028] Step S1: Use the knock sensor to judge whether there is super knock in the engine cylinder during the working cycle, if yes, go to step S2;

[0029] Step S2: In the following 2 working cycles C 1 and C 2 In the process, the fuel injection timing of the cylinder with super knock is postponed, and at the same time, it is judged that the cylinder is in the next working cycle C 3 Whether superknock occurs, if not, then in C 3 restore the fuel injection timing of the cylinder to the calibration working condition; if yes, proceed to the next step.

[0030] Wherein, in step S2, delaying the fuel injection timing of the super-knocking cylinder includes: delaying the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com