A constant-pressure start-up method for hot waxy crude oil pipeline

A technology for oil pipelines and high-pressure startup, which is applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc. It can solve problems such as inapplicability, and achieve the effect of improving the success rate and reducing the risk of stoppage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

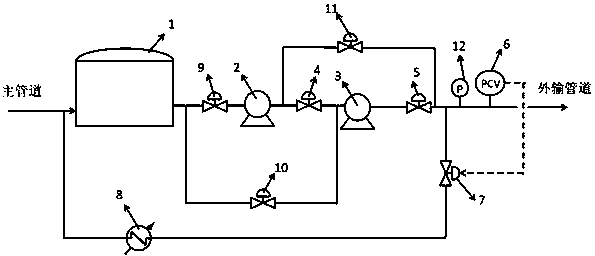

[0038] Such as figure 1 As shown, the waxy crude oil pipeline system of the present invention includes a main oil pump 2, a backup pump 3, an oil pipeline, a buffer tank 1, a process switching valve 4, a pressure relief valve 5, a pressure control system and an internal circulation pipeline 13;

[0039] When the stopped pipeline system is restarted, the standby pump 3 is connected in series to the oil pipeline so that it is located downstream of the main oil pump 2; An internal circulation pipeline 13 is set between the outlet of the first-stage oil delivery pump, that is, the outlet of the backup pump 3 and the inlet of the buffer tank 1, and a branch flow regulating valve 7 is arranged on the internal circulation pipeline; The opening of the road flow regulating valve is used to control the crude oil flow through the internal circulation pipeline, so as to realize the constant high-pressure startup of the crude oil pipeline; when the pressure of the waxy crude oil in the ext...

Embodiment 2

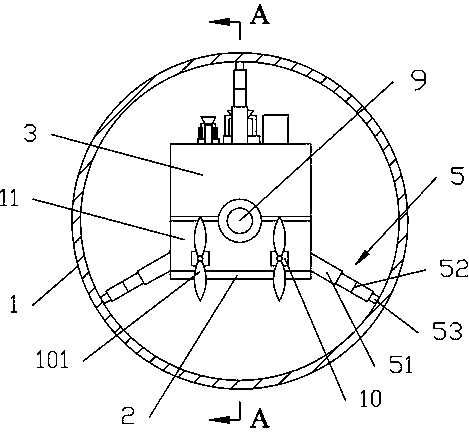

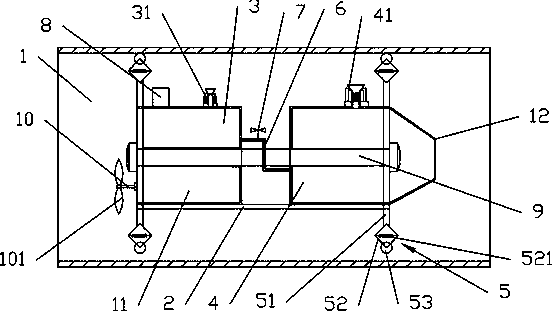

[0046] Such as Figures 2 to 3 As shown, the waxy crude oil pipeline auxiliary starting device used in the present invention includes: vehicle frame 2, liquid storage tank 3, reaction tank 4, control system 8 and propulsion system, and the propulsion system is installed on the vehicle frame 2 for promoting Frame 2 moves. The liquid storage tank 3 and the reaction tank 4 are respectively equipped with reactants for the reaction to generate gas, that is, the liquid storage tank 3 is used to contain the liquid first reactant, and the reaction tank 4 is used to contain the second reactant. The reactant and the second reactant can react to form a gas. The liquid storage tank 3 and the reaction tank 4 are installed on the vehicle frame 2 respectively, and the liquid storage tank 3 is higher than the reaction tank 4, and the liquid storage tank 3 and the reaction tank 4 are communicated through a conduit 6, and one end of the conduit 6 is connected to the liquid storage tank 3 The ...

Embodiment 3

[0060] This embodiment is basically the same as Embodiment 1, except that the wheel mechanism of this embodiment adopts 4 wheels, and the 4 wheels are arranged in a rectangular shape at the lower position of the vehicle frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com