Construction method for filling concrete in steel tube arch bridge tube

A construction method and technology for steel pipe arch bridges, applied to arch bridges, bridges, bridge forms, etc., can solve problems such as time-consuming, labor-intensive, difficult pumping and jacking, and easy interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

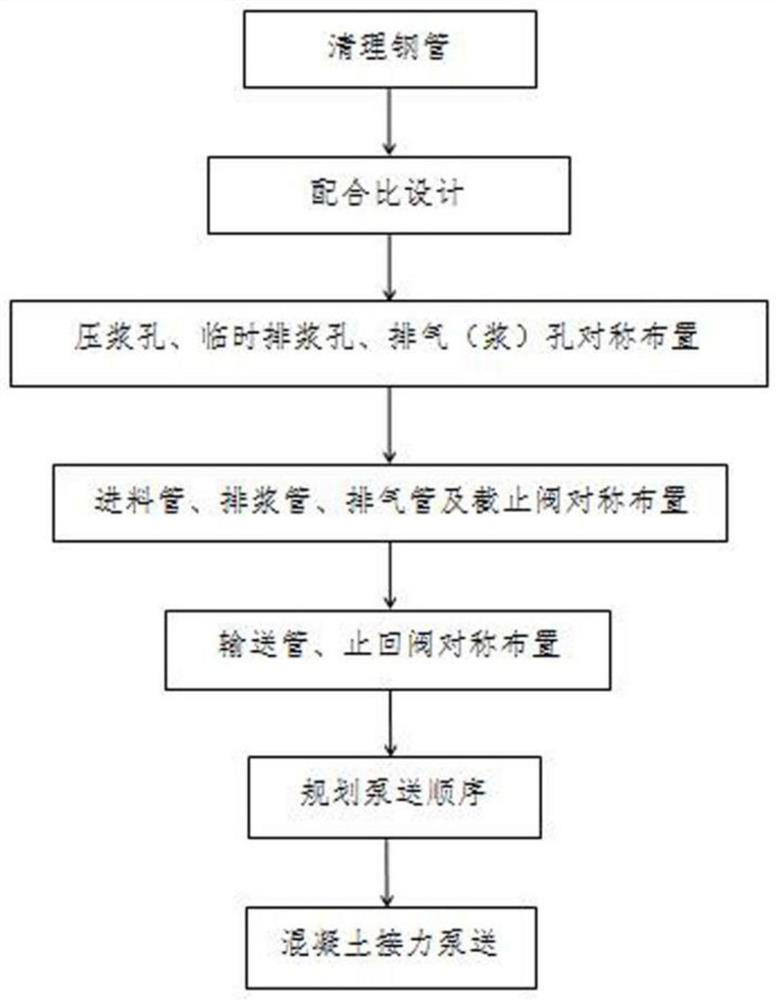

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

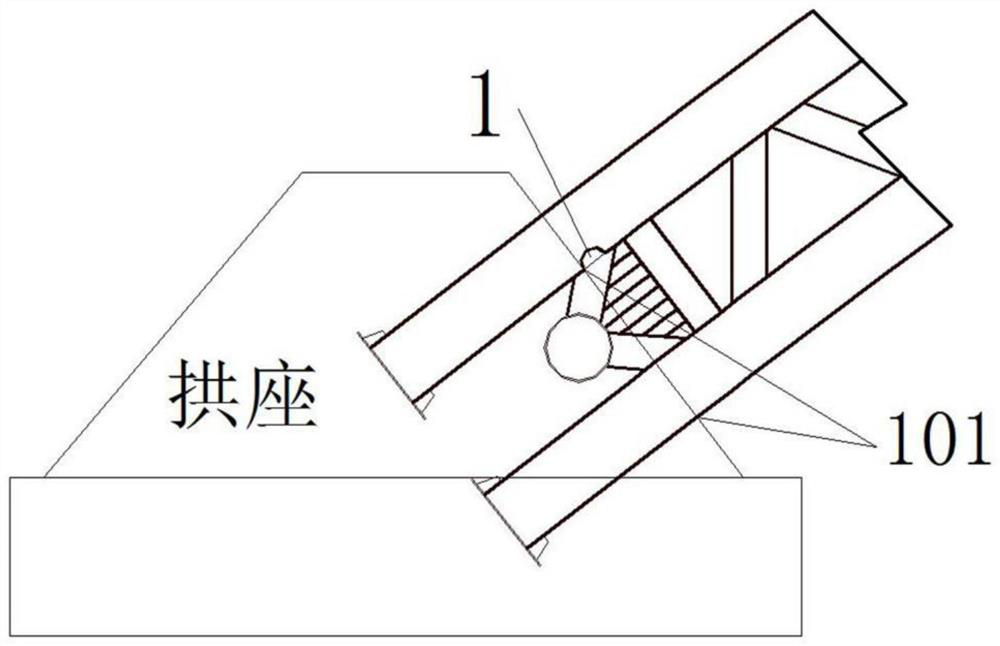

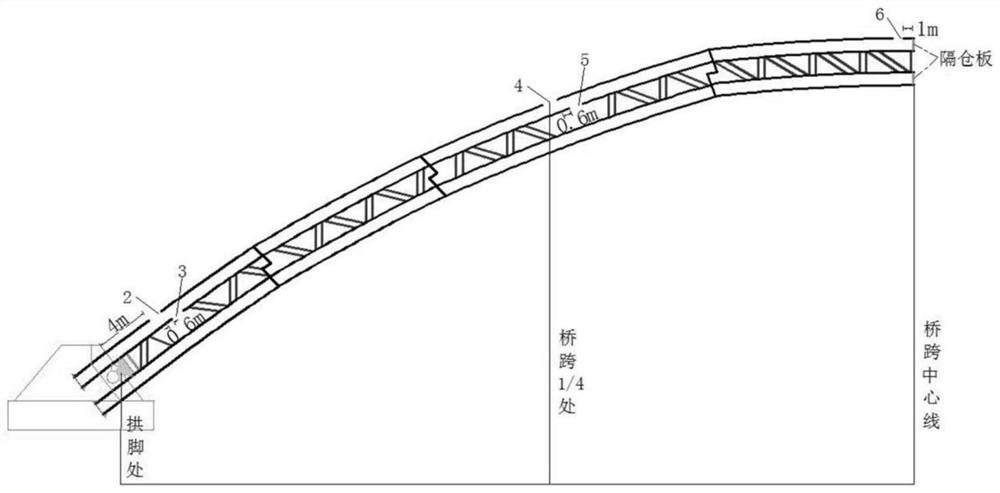

[0039] The control project of the reconstruction project of the Daishan section of National Highway 526—Xinjiangnan Bridge spans the Pumen Waterway. The diameter is 205m, the calculated rise height is 38.68m, and the calculated rise-span ratio is 1 / 5.3. The arch rib of the whole bridge is composed of two steel pipe concrete trusses with equal cross-section, each truss is composed of 4 φ1000mm steel pipes, the length of the upper chord of the main arch rib is 228m, the length of the lower chord is 224m, and the pressure injection in a single pipe is 160m 3 Self-compacting micro-expansion C50 concrete.

[0040] The main arch rib of the New Jiangnan Bridge uses a single steel pipe as a unit, longitudinally symmetrical, synchronous, one-time, step-by-step, continuous pumping, jacki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sand rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com