Pipeline leakage monitoring method and control unit, device and system

A technology of a control unit and a monitoring device, which is applied to the pipeline drip monitoring method, control unit, device and system field, can solve the problems of too narrow detection range, increased starting inertia, poor general type, etc., and achieves low power consumption and large Effect of detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

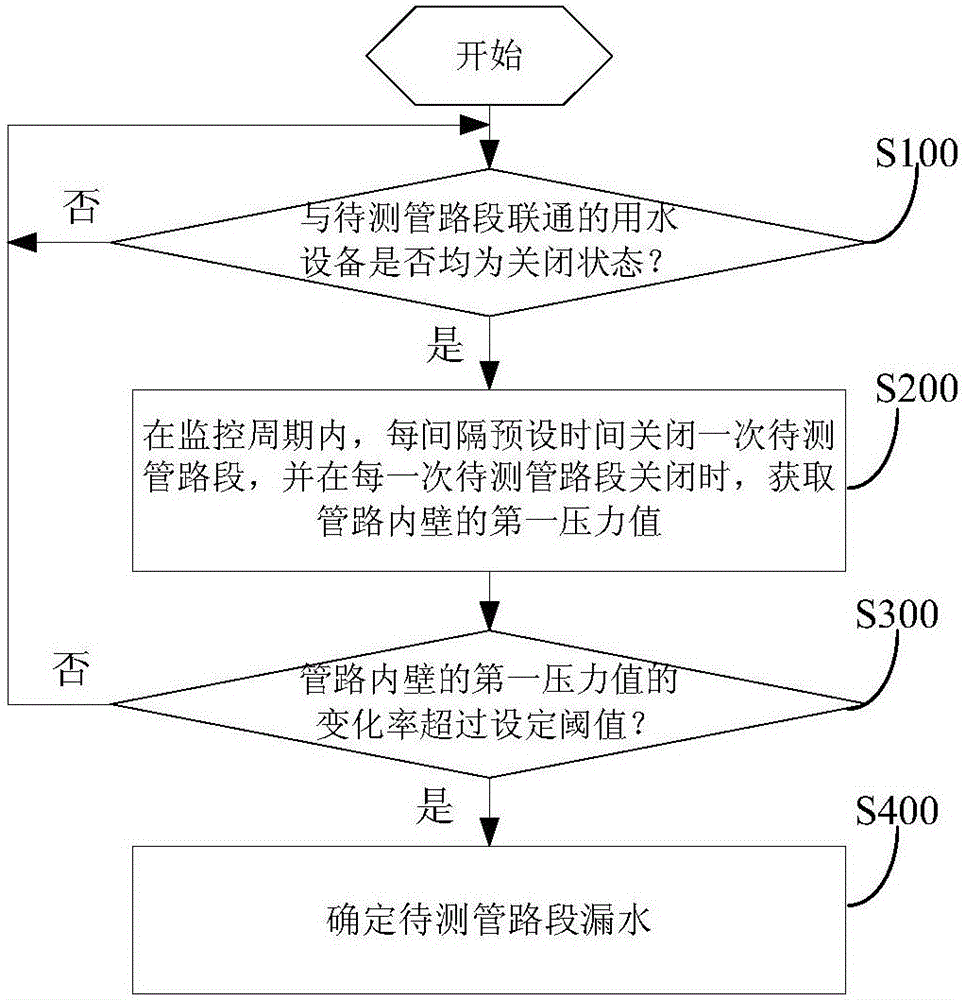

[0061] This embodiment provides a pipeline drip monitoring method, which is applied to equipment for detecting water leakage in domestic water pipelines. The pipelines include water outlet equipment and water pipelines. The water outlet equipment may include showers, kitchen faucets, Toilet water tank, etc., the water pipeline is a pipeline for water circulation. Such as figure 1 shown, including the following steps:

[0062] S100: Judging whether all the water equipment connected to the pipeline section to be tested are in the off state, if so, start the monitoring mode, and perform step S200; that is, only when the water equipment connected to the pipeline section to be tested are all in the off state, start the monitoring mode , to close the section of the pipe to be tested, thereby avoiding affecting the normal water use of the water-using equipment.

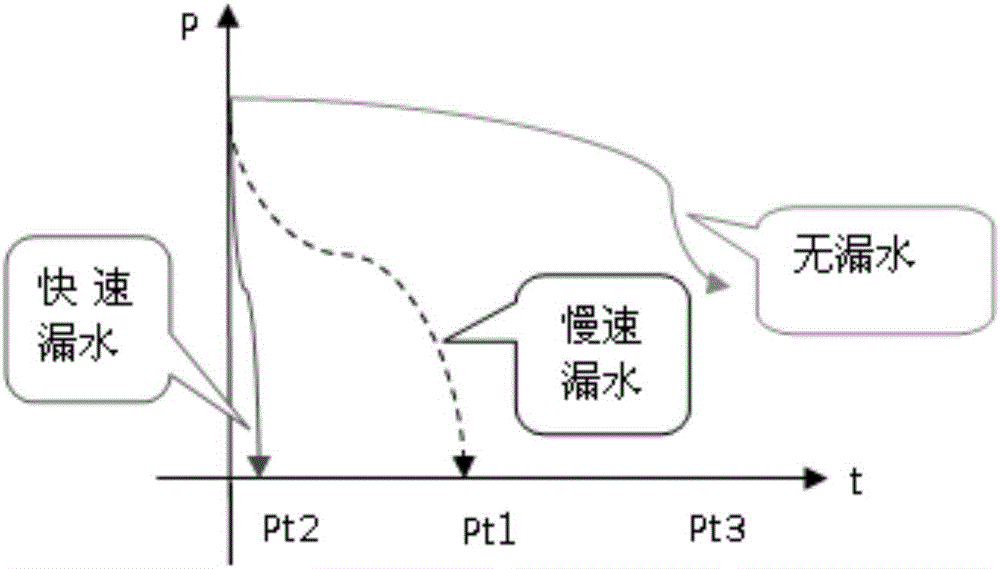

[0063] S200: Execute the monitoring mode, and within the monitoring period, close the section of the pipeline to be test...

Embodiment 2

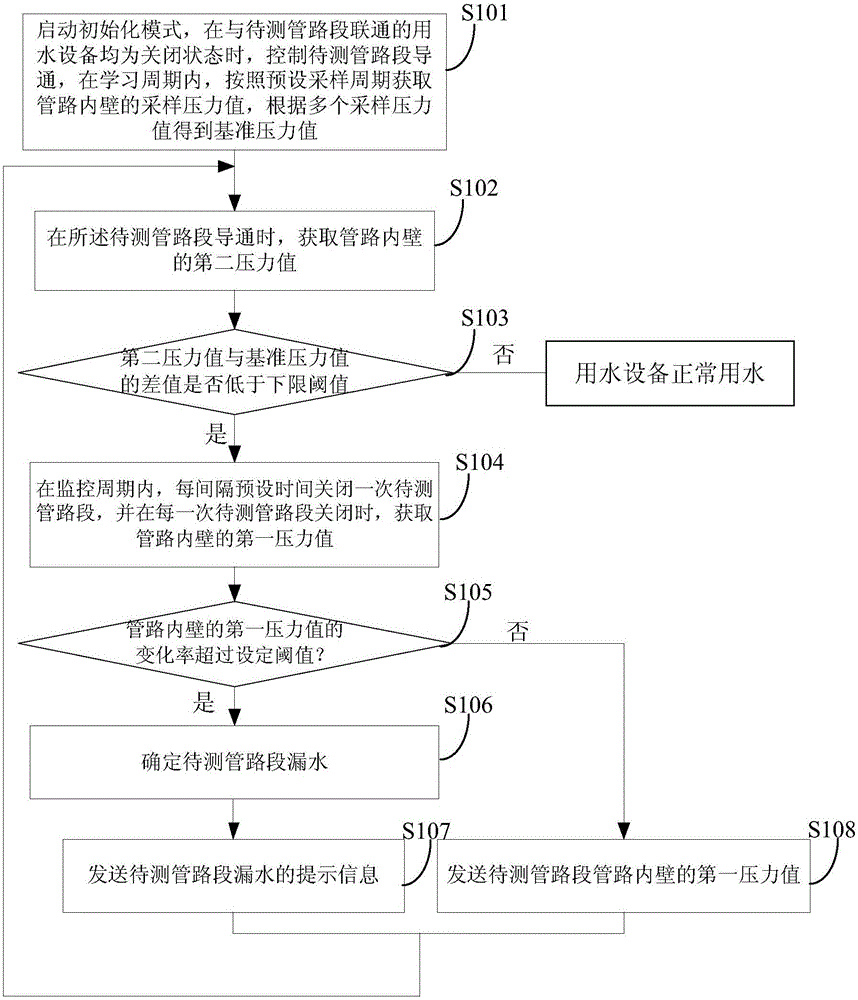

[0069] The pipeline leakage monitoring method provided in this embodiment, such as image 3 shown, including the following steps:

[0070] S101: Start the initialization mode. When the water equipment connected to the pipeline section to be tested is closed, control the conduction of the pipeline section to be tested. During the learning period, obtain the sampling pressure value of the inner wall of the pipeline according to the preset sampling period , obtaining a reference pressure value according to the plurality of sampled pressure values. The learning period may be set as a fixed period, such as ten minutes. The sampling period can be selected as ten seconds, and the reference pressure value is obtained according to the results obtained from multiple samplings. When processing multiple sampled pressure values, filtering, noise reduction and other processing methods are used to eliminate the influence of occasional abnormal values. Use the finally obtained reference pr...

Embodiment 3

[0085] This embodiment provides a control unit, such as Figure 4 shown, including:

[0086] Judgment module 101, judges whether the water equipment connected with the pipeline section to be tested is all closed, and if so, starts the monitoring mode; that is, only when the water equipment connected with the pipeline section to be tested is all closed, the monitoring mode is turned off. The pipe section to be tested can avoid affecting the normal water use of water equipment.

[0087] The monitoring module 102 executes the monitoring mode, and within the monitoring period, closes the pipe section to be tested at intervals of a preset time, and obtains the first pressure value of the inner wall of the pipe every time the pipe section to be tested is closed; The monitoring cycle is set according to the actual household water use conditions. For example, in the morning and evening, when the household water equipment is turned on more often and the water is used more frequently, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com