Low-resistance column type ultrasonic heat meter pipe section

A column type, ultrasonic technology, applied in the direction of measuring devices, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve the problems of unfavorable pipeline impurity removal, increase the pressure loss of pipe sections, and the influence of heat meter pressure loss, etc., to achieve structural Simple, reduce pipeline blockage, low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

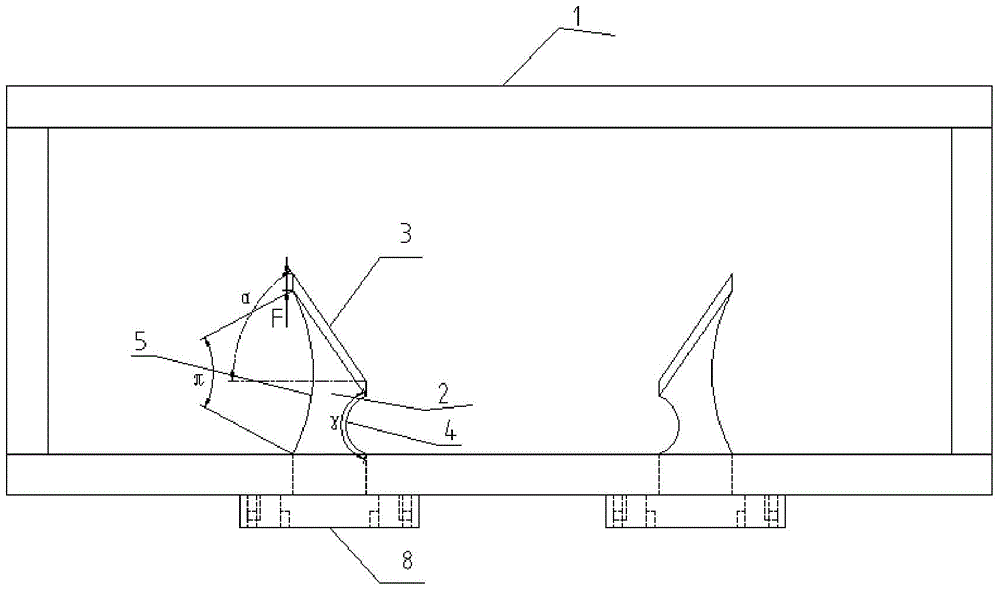

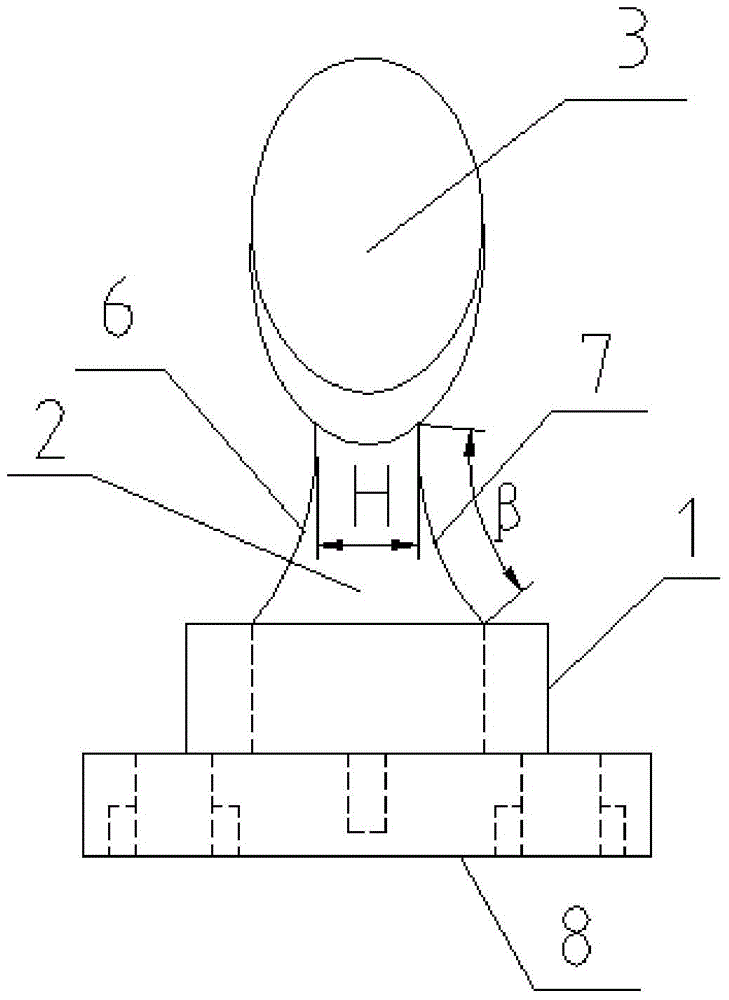

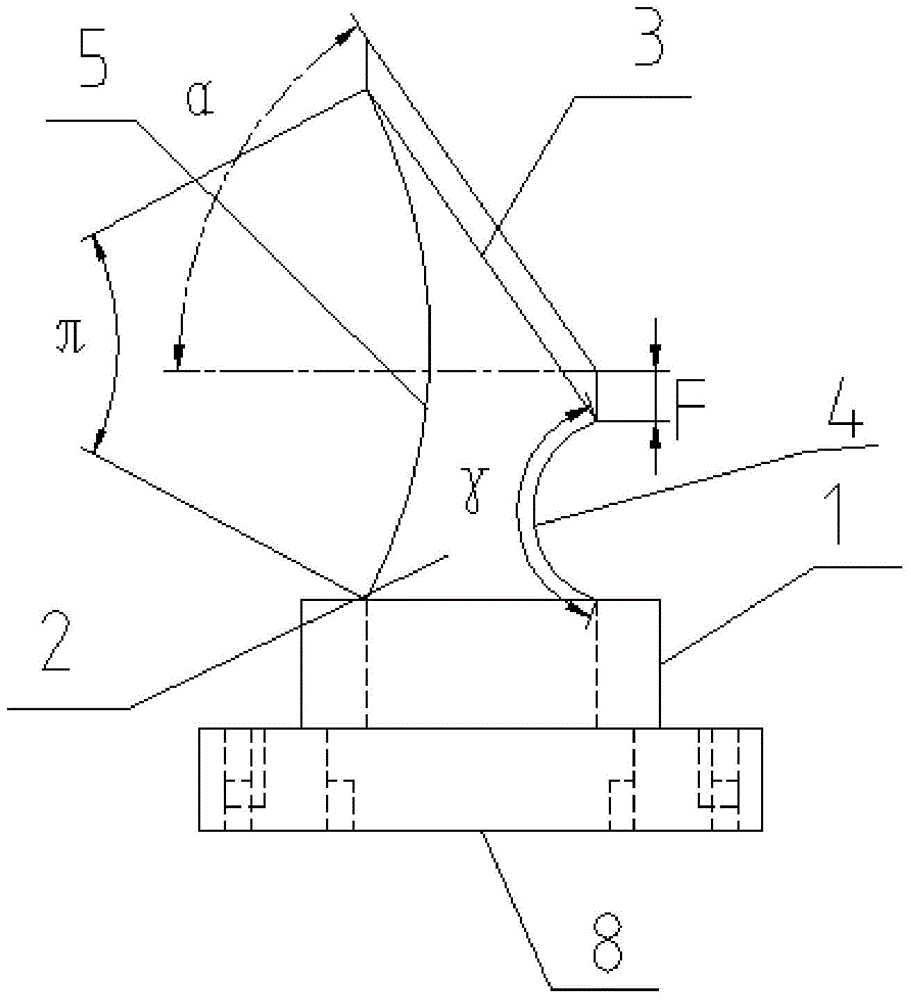

[0017] like figure 1 , 2 , 3, and 4, a low-resistance column-type ultrasonic heat meter pipe section of the present invention includes a pipe section body 1 and two reflection columns 2; the upper end faces of the two reflection columns 2 are provided with a reflection surface 3, two The reflection columns 2 are all arranged in the pipe section body 1, and the distance between the two reflection columns 2 and the midpoint of the pipe section body 1 is 12 mm; the reflection columns 2 include arc-shaped front walls 4. The rear wall 5, the left wall 6, and the right wall 7, the left wall 6 and the right wall 7 are left-right symmetrical structures, the radian β of the left wall 6 and the right wall 7 is 47°, and the radius is 10.2mm , the distance H between the tangents of the left wall 6 and the right wall 7 is 4mm, the arc γ of the front wall 4 is 142.2°, and the radius is 3.7mm, and the arc π of the rear wall 5 is 56.1°, and the radius 21.25mm; the two reflective surfaces 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com