Cooling device for working machine

A technology for cooling devices and operating machinery, applied in engine cooling, mechanical equipment, air cooling, etc., can solve problems such as inability to clean, increased pressure loss on the suction side, and inability to swing out the heat exchanger 11, etc., to achieve easy cleaning , Simple installation structure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

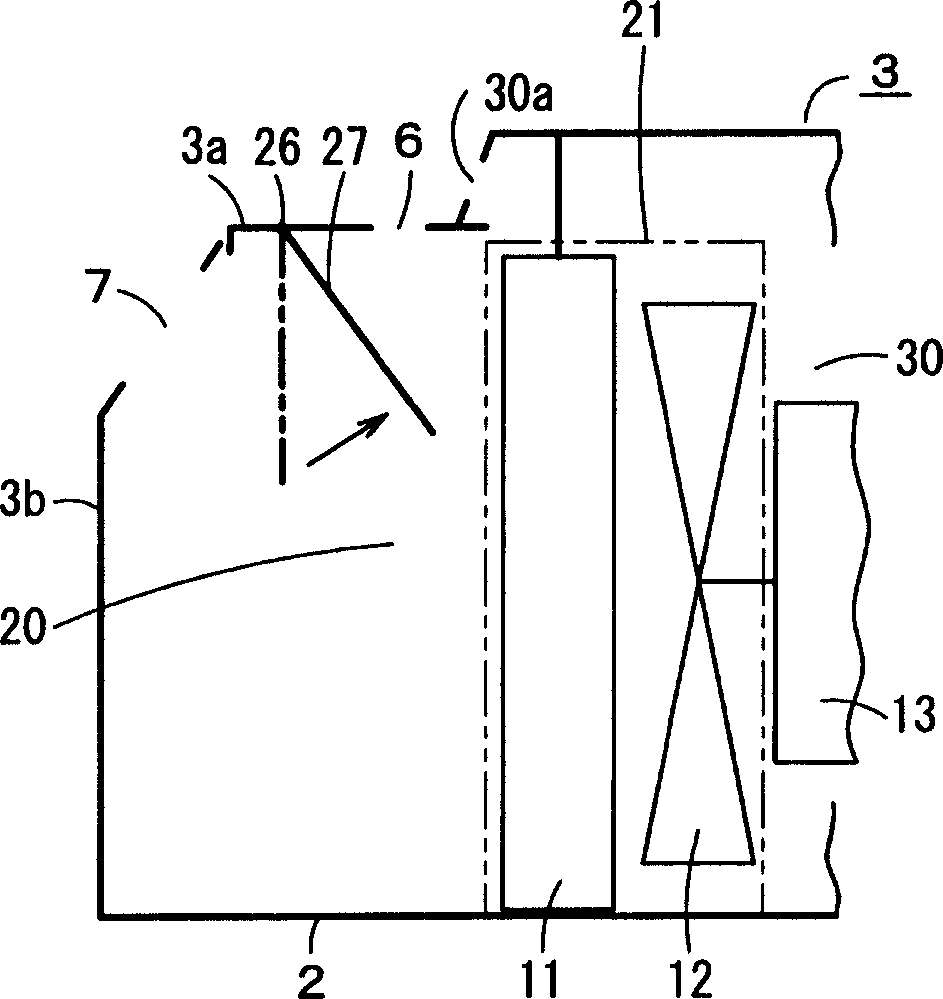

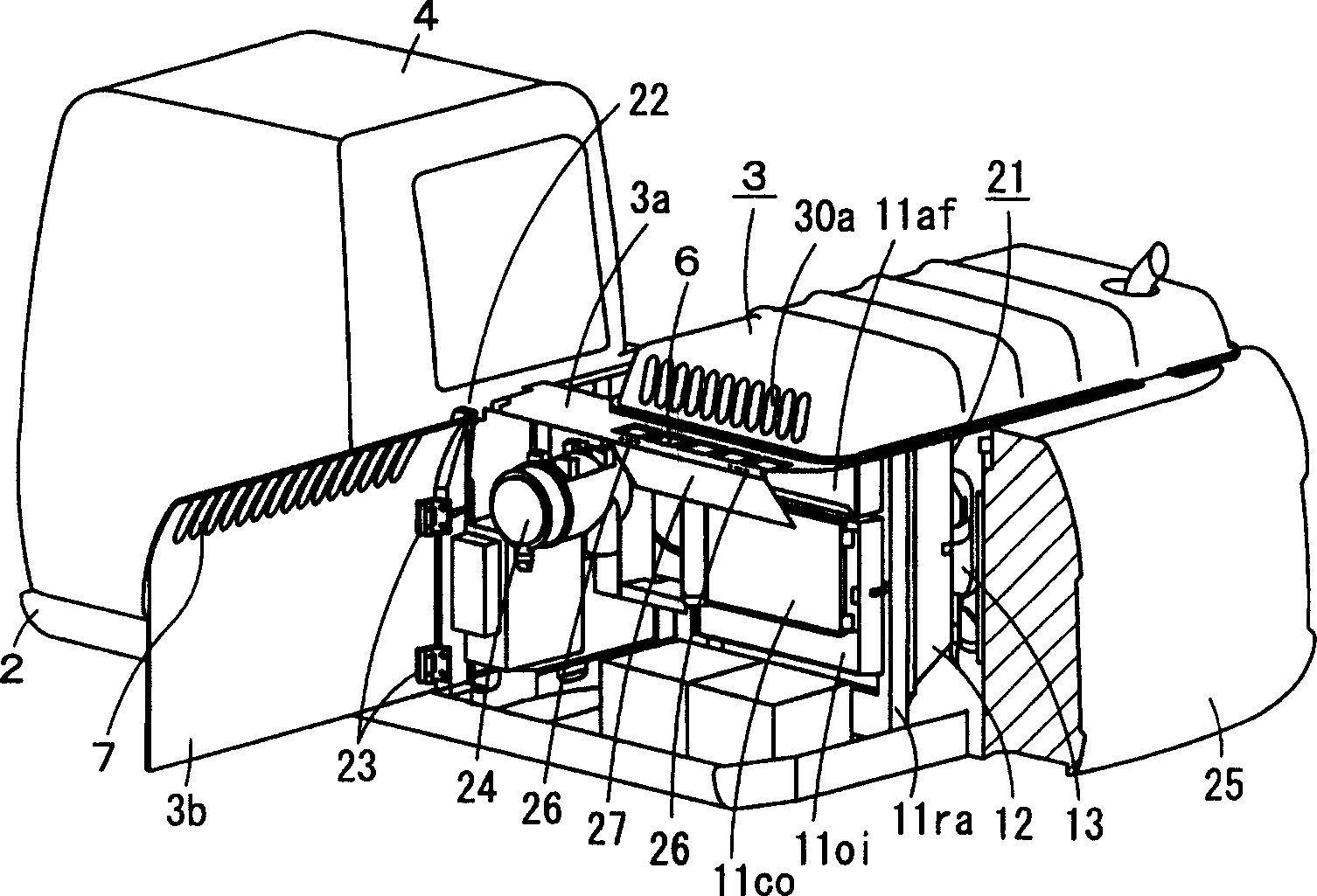

[0072] Below, refer to Figure 1 to Figure 17 The various embodiments shown illustrate the invention. In addition, in the description of the present invention, the hydraulic excavator as the working machine shown in FIG. 18 is also referred to, so the parts corresponding to the parts in FIG. 18 are given the same reference numerals.

[0073] based on Figure 1 to Figure 3 , Embodiment 1 of a cooling device for a hydraulic excavator will be described.

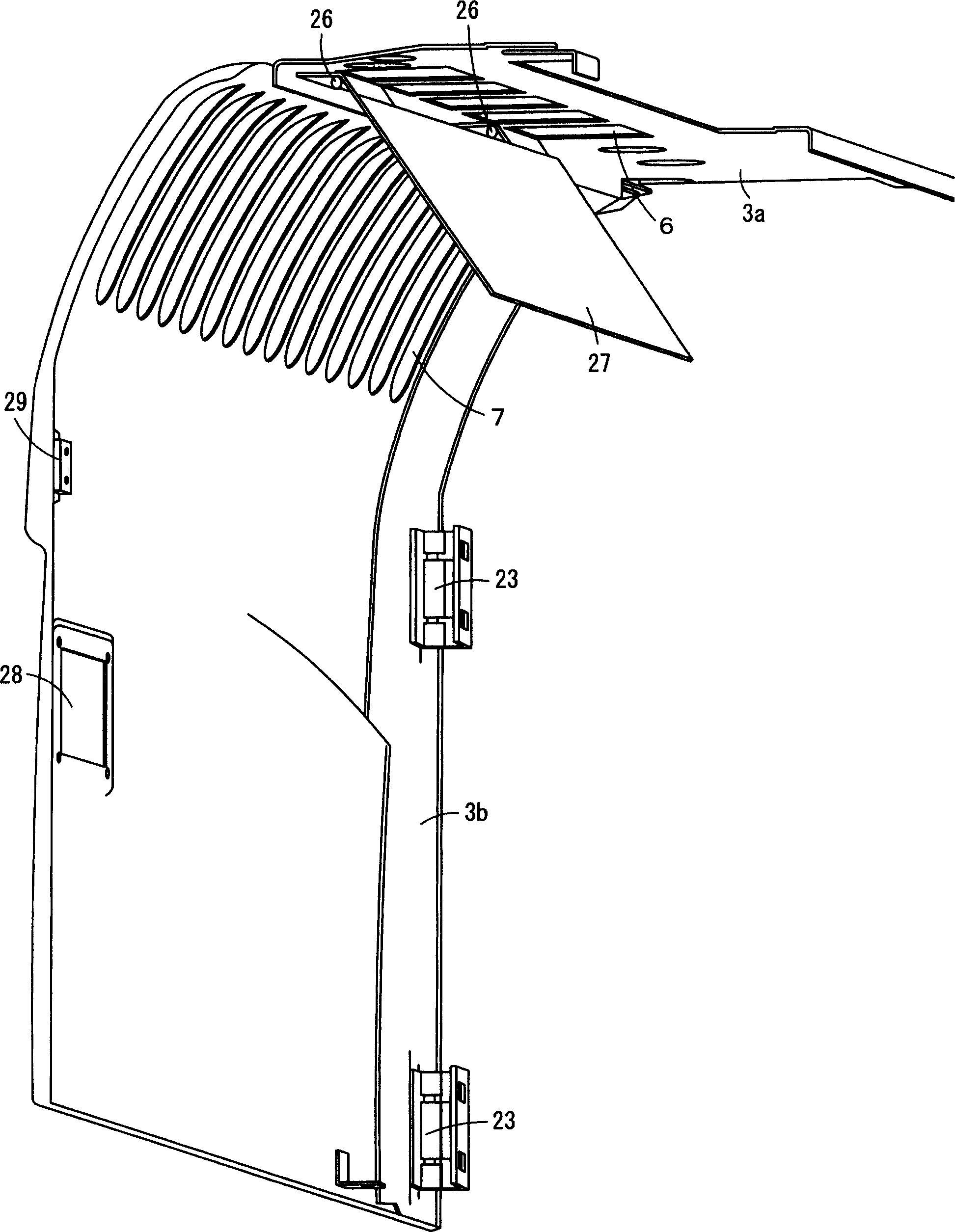

[0074] Such as figure 1 As shown, in the cooling device room 20 of the hydraulic excavator, a cooling assembly 21 is provided. The cooling assembly 21 has a heat exchanger 11 and a cooling fan 12 for cooling a radiator of the engine, and is covered by a cover 3. 21 and engine 13. The cover 3 has an upper cover 3 a provided above the cooling unit 21 , and a side door 3 b serving as a side cover provided on one side of the upper cover 3 a and facing the cooling unit 21 .

[0075] Such as figure 2 As shown, the side door 3b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com