Novel LED Lamp and implementation method thereof

A technology of LED lamps and LED lamp beads, which is applied in the direction of lighting and heating equipment, light sources, components of lighting devices, etc., can solve the problems of no improvement in heat dissipation and high cost, and achieve good heat dissipation effect, high production efficiency, and stable connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

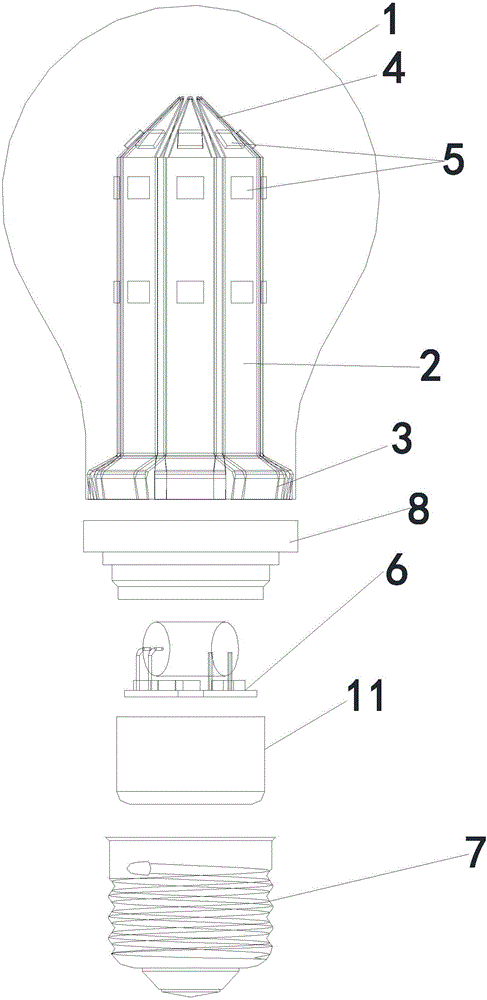

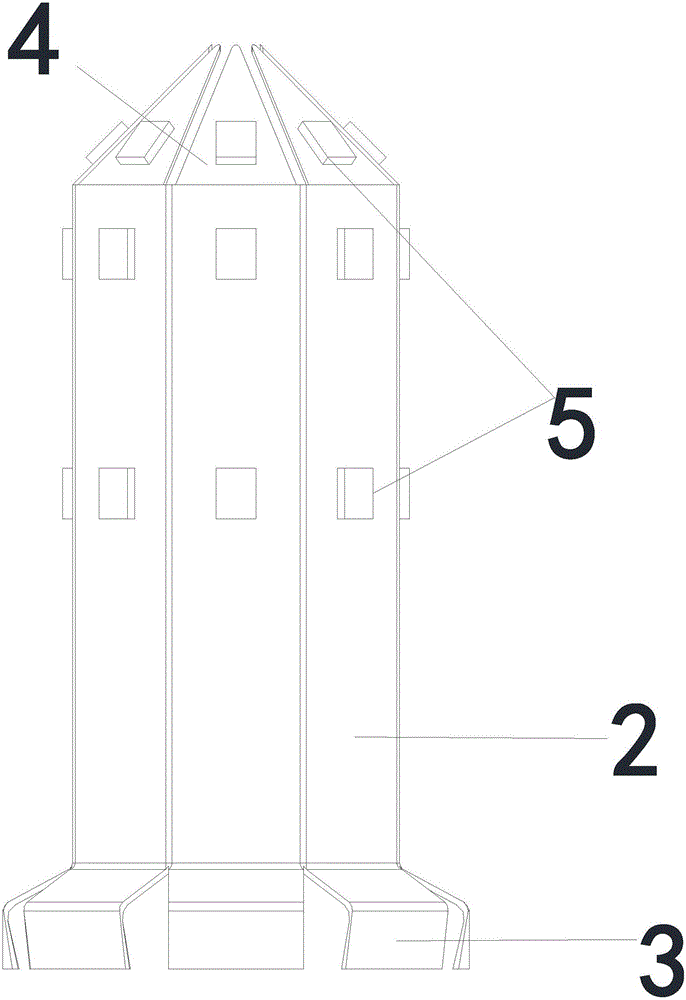

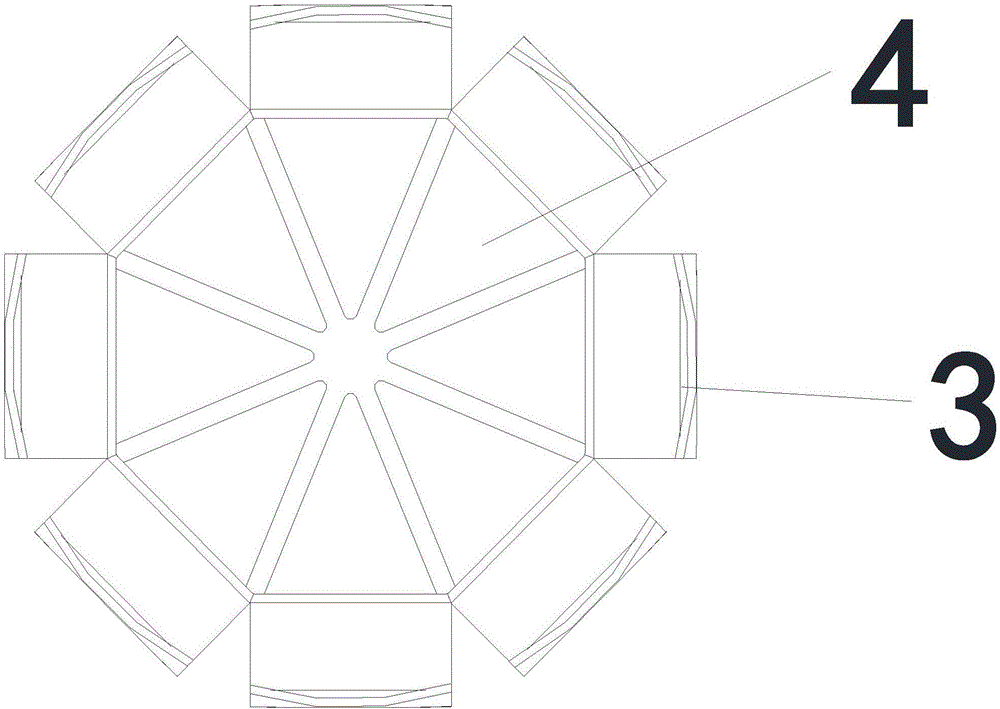

[0035] like Figure 1~3 As shown in 5 and 5, a new type of LED lamp includes a bulb, and an LED substrate is arranged in the bulb. The lower part of the LED substrate is folded into a columnar body by a plurality of quadrilaterals. The lower part of the columnar body is provided with a folding installation part. The triangle is folded into a cone. There are several LED lamp beads on the outer surface of the column and the cone. The folded installation part is connected to the bottom of the bulb. The shells are fitted together and then fixed on the support frame, which is connected to the lamp cap. The upper part of the support frame has a ring groove for putting the bulb and the folding installation part into it. The lower part and the upper part have steps to facilitate the connection of the lower part and the lamp cap.

[0036] The LED lamp beads in this embodiment are adjusted according to actual design needs. The LED substrate is made of high thermal conductivity materials...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that a connection and fixing piece is provided in the middle of the columnar body in this embodiment, and the connection and fixing piece includes a polygonal body, and claws are provided around the polygonal body, and the claws pass through the clamping holes on the columnar body. slot fixed. The columnar body can have 3-10 faces, and the columnar body in this embodiment has 8 faces, with a thickness of 0.3-1 mm. The purpose of this structural design is to increase the strength of the LED substrate, improve the uniformity, and ensure uniform light emission and use effect.

Embodiment 3

[0049] like Figure 4 As shown, the difference between this embodiment and Embodiment 2 is that the stem in this embodiment is fixed through the middle of the connecting and fixing piece, and the fixing method is fixed by the elastic piece. The purpose of the design is to further improve the use effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com